|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Senior Member

Join Date: May 2010

Location: Spokane, WA

Posts: 2,976

|

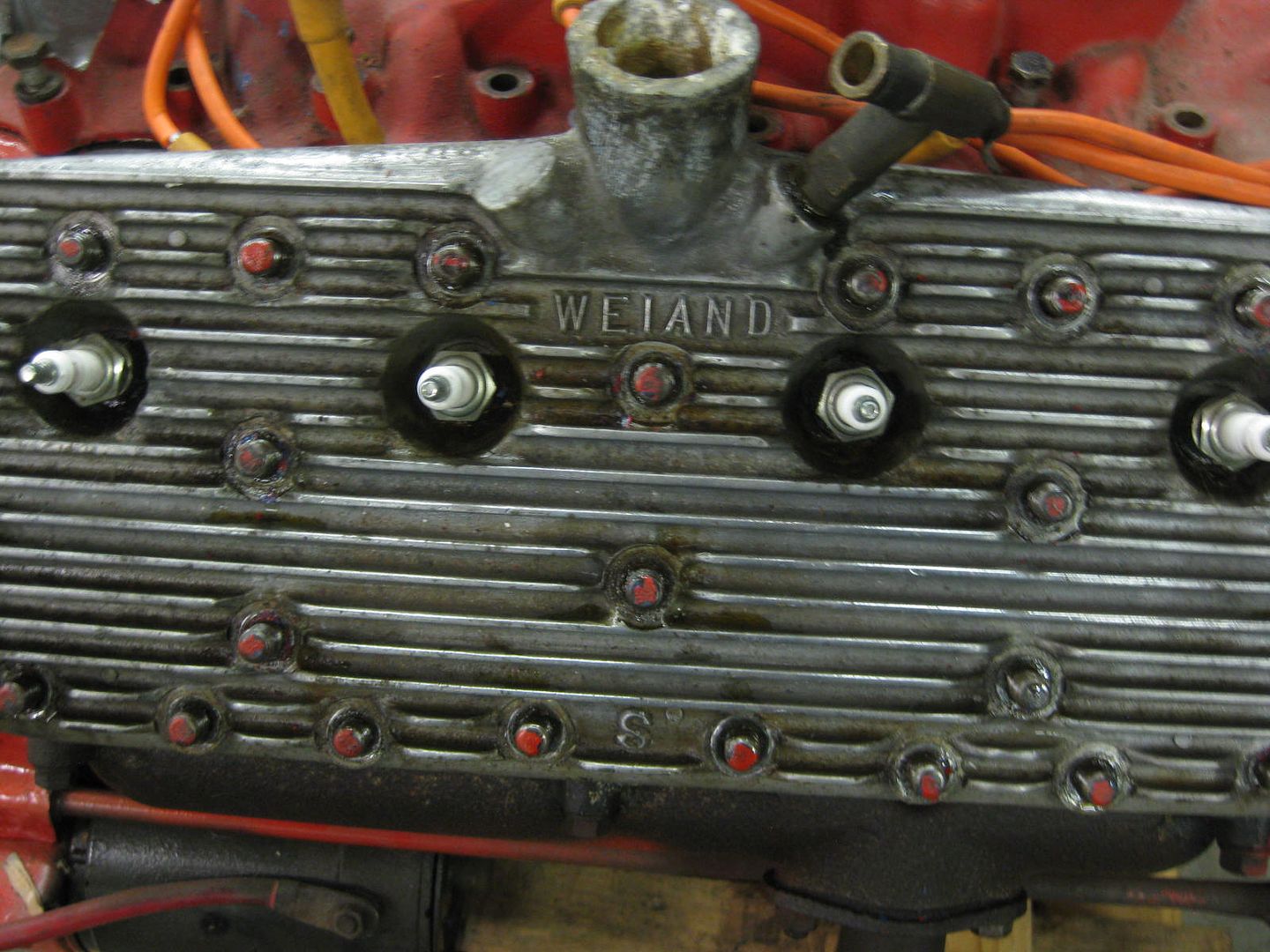

I thought I could get em, but man they are not budging! I am being very careful however as not to damage the heads. I got this engine a week ago, been squirting penetrating oil on each stud every day since! I have tried cranking it over with the plugs in, made some T handle pullers using spark plugs to thread into the holes, tapped and tapped on em all over...they will just not budge. Anyone else run into some suborn ones? How did you get em off without damaging anything?

__________________

Thee Inland Emperors |

|

|

|

|

|

#2 |

|

Senior Member

Join Date: May 2010

Location: Florence Ma.

Posts: 2,404

|

Have you tried the Rope in the cylinder trick ?

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#3 |

|

Senior Member

Join Date: Jan 2012

Location: Roswell NM

Posts: 162

|

I used a heat gun on the studs

|

|

|

|

|

|

#4 |

|

Senior Member

Join Date: Sep 2010

Location: Independence, VA

Posts: 423

|

Looks like you have everything there you need to start it up,,,,

|

|

|

|

|

|

#5 |

|

Senior Member

Join Date: Apr 2011

Location: Oregon

Posts: 220

|

I made a head puller using a steel plate with holes to match the plug locations.

Then remove the innards from some old plugs and tap them. Screw all-thread into the tapped plugs. With the plugs in the head, place the steel plate down on the studs with the all-thread sticking through the holes in the plate. Put nuts onto the all-thread and as you tighten the nuts the head will lift up. Once the top of the head reaches the top of the studs remove the steel plate and switch to some wooden wedges to get the head the rest of the way off. My original design has 4 holes in the plate because I thought that I might need the lifting power of all 4 plugs. But the two outside ones were more than enough to do the job. I also used channel rather than a flat steel plate because it would be more rigid. That was also overkill. A 1/4" steel plate should be strong enough. I could take some pictures if you need more info. Tom |

|

|

|

|

|

#6 |

|

Senior Member

Join Date: May 2010

Location: Kokomo, Indiana

Posts: 1,731

|

Sponsored Links (Register now to hide all advertisements)

|

|

|

|

|

|

#7 |

|

Senior Member

Join Date: May 2010

Location: Northeast Pennsylvania

Posts: 1,582

|

I'd get a stud-puller and remove as many studs as possible.

|

|

|

|

|

|

#8 |

|

Senior Member

Join Date: May 2010

Location: middle of Iowa

Posts: 651

|

|

|

|

|

|

|

#9 |

|

Senior Member

Join Date: May 2010

Posts: 1,835

|

This would be the worse way to use a stud puller,if you could even get a good grip on about 1/2"-5/8" area that is threaded you are pulling studs from the very top. This would enable entire stud out of block to twist and break,you need to use stud puller as low to block as you can get.

__________________

"Never complain,never explain"... Henry Ford II |

|

|

|

|

|

#10 | |

|

Senior Member

Join Date: May 2010

Location: NJ

Posts: 6,231

|

Quote:

There was a thread about this a few weeks ago that may be worth while checking out. |

|

|

|

|

|

|

#11 |

|

Senior Member

Join Date: Jul 2011

Location: SF Bay Area

Posts: 6,671

|

Chris, check the comments on the "penetrating Oil" thread. Looks like a 50/50 home brew of ATF fluid and Acetone gets better reviews than any of the commercial products.

__________________

Alan |

|

|

|

|

|

#12 |

|

Senior Member

Join Date: May 2010

Location: West Michigan

Posts: 1,218

|

47COE-

I have thought about doing something like what you have done but isn't there a danger of stripping the spark plug threads especially with very stuck aluminum heads? Pictures are always nice! Thanks Tom |

|

|

|

|

|

#13 |

|

Senior Member

Join Date: May 2010

Location: Solihull, England.

Posts: 8,777

|

I've never seen one, but I have heard of very thin hole saw type tools that you use to cut down through the corrosion. They would probably take out some head material too. Commonly used on older Brit stuff.

Would it be worth sacrificing the studs? Weld nuts on them, remove as many as will come out and then The heads should come off a lot easier. Then you would have a bunch of broken studs to deal with, but that may be the case no matter how you do it. Mart. |

|

|

|

|

|

#14 | |

|

Senior Member

Join Date: Apr 2011

Location: Oregon

Posts: 220

|

Quote:

The failsafe is the threads tapped into the plug to receive the all-thread rod. The inside diameter of the plug is a bit big for the nearest size tap. So the threads aren't full depth. Even if the head was totally welded to the block and you applied gorilla force, the all-thread would pull out of the plug long before the plug threads would strip out of the head. I'll see about taking photos tomorrow. Tom |

|

|

|

|

|

|

#15 | |

|

Senior Member

Join Date: May 2010

Location: Northeast Pennsylvania

Posts: 1,582

|

Quote:

I actually had a spark plug explode out of an aluminum head, fly right by my head, dent the underside of my hood, and continue across the garage. |

|

|

|

|

|

|

#16 |

|

Senior Member

Join Date: Jun 2011

Location: Oregon

Posts: 315

|

I have used Tom's puller and it is easy. I had heads that were really stuck on my 36 and they came off without any force on the nuts that do the pulling. That is the nuts that are on the all thread that goes through the old plugs. The secret seems to be the force is in just the right place and in the right direction. It works.

Bill |

|

|

|

|

|

#17 |

|

Senior Member

Join Date: Aug 2012

Location: Nebraska

Posts: 603

|

How about throwing air pressure to a cylinder with both valves closed? Piston will go to BDC but you'll put 125 psi air to the cylinder?

Just need a modified plug to accept an air line quick connect. If you think 125 psi is to much you could regulate it to less and increase as needed. |

|

|

|

|

|

#18 |

|

Senior Member

Join Date: May 2010

Location: Florida and Penna.

Posts: 4,471

|

I have several thin hole saws that were made for this purpose. There is a holder with a "T" handle or can be usd with an electric drill. It is 7/16" ID and 1/2" OD. This leaves a .032 wall thickness.You have to be careful or they can break. If you could find a 7/16 iD deep hole saw the OD could be turned or if to hard ground to 1/2. This removes them and very little material is removed it's all corrosive junk. Some of these heads are so porous they pull apart or break if the original Ford or KRW chisel type head puller is used. These looked like ice tongs. G.M.

__________________

www.fordcollector.com |

|

|

|

|

|

#19 |

|

Senior Member

Join Date: May 2010

Location: so cal, placerville, vegas

Posts: 1,396

|

Lots of choices here. I never had much luck with the little hole-saws - they just seem to gum up, and they also tend to enlarge the hole in the head, which I would prefer not doing. My preference is the arc-welded-on nut, then hammer them with a substantial air-driven impact wrench. Work the impact on 'forward', and 'reverse', on the really stuck ones. (Don't try to muscle them off with a wrench or breaker-bar. That's how you end up with broken studs.) The studs are sacrificed, but the heads are not damaged.

|

|

|

|

|

|

#20 |

|

Senior Member

Join Date: May 2010

Posts: 2,174

|

scrapiron>>>Looks like you have everything there you need to start it up>>>

x2. Don't rev it up too much though. 8^) Jack E/NJ |

|

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 04:13 PM.

Linear Mode

Linear Mode