|

|

|

|

#1 | |

|

Senior Member

Join Date: May 2010

Location: South California

Posts: 6,190

|

Quote:

Very good info for all who care to know details of this matter, and not rely on old tales and hearsay that has been passed on. NOW, maybe this will be passed on and help those with axle problems...but do not know WHY ! Proper amount of Model A axle nut torque has not been discussed, so far. Just what is the proper amount ? When the number of ft lbs is told, the number is NOT believed by most...why ? Without new axles/nuts, Model A owners say....oh, that's not right, is tooo much, I just torque them till their tight  ! !Again, if not lapped right, and not torqued right....nothing is right according to the excellent info that has been provided above. |

|

|

|

|

|

|

#2 |

|

Senior Member

Join Date: Jul 2012

Location: Venice, FL

Posts: 667

|

Bob C,

Thanks for the explanation on self holding tapers. The model 'A' axle tapers and hubs, (sleeves) I've seen are everything but accurate and honed tapers. Mine are pitted warn and gouged. And in many cases not torqued to 100 plus pounds. Thanks for mentioning the use for light and heavy load uses for keyed and non-keyed applications. Al Leach |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#3 | |

|

BANNED

Join Date: May 2010

Location: Wa.

Posts: 5,423

|

Quote:

Read and understand the LAST paragraph in the above BobC's post #17. Bt lapping the hub to the axle and getting a 100% surface, you can run WITHOUT a key in a STOCK model A application. It is NOT a heavy duty application. HOWEVER, it is near to impossible to get 100% surface on an axle and hub with machined surfaces that has been run/abused, corroded and pitted. |

|

|

|

|

|

|

#4 |

|

Senior Member

Join Date: May 2010

Location: South California

Posts: 6,190

|

The original keys are cheap/easy to obtain and made as Ford made them to perform intended function. I'd stay with that metal / key.

Because of the fit of the rear axle/hub, I occasionally check/recheck to ensure proper torque. IMO, you WILL be surprised at what you find, that is, that re-torque check is worthwhile. Only possible exception would be 'perfect' mating/lap joint, IMO. |

|

|

|

|

|

#5 |

|

Senior Member

Join Date: Dec 2010

Location: FRESNO, CA

Posts: 12,560

|

If only the taper were needed for grip, then WHY did Henry do all the extra work to put in a KEY????---Are we over thinking this thing????

Bill Commonsense

__________________

"THE ASSISTANT GURU OF STUFF" |

|

|

|

|

|

#6 |

|

Senior Member

Join Date: May 2010

Location: now Kuna, Idaho

Posts: 3,818

|

Sponsored Links (Register now to hide all advertisements)

|

|

|

|

|

|

#7 | |

|

Senior Member

Join Date: Dec 2010

Location: FRESNO, CA

Posts: 12,560

|

Quote:

They WERE there! They WERE there!Bill Notsosure

__________________

"THE ASSISTANT GURU OF STUFF" |

|

|

|

|

|

|

#8 |

|

Senior Member

Join Date: Mar 2015

Location: Freetown, Massachusetts

Posts: 511

|

When I bought my Model A, one side of the rear axle had a "REX A " carbon steel tool bit for a key. It had been used as a lathe tool.

When we disassembled the rear axle and housing, we were faced with an entire rebuild including axles. What a mess;

__________________

Brian French; 1930 Briggs Town Sedan |

|

|

|

|

|

#9 |

|

Senior Member

Join Date: Mar 2017

Location: Connecticut Shoreline

Posts: 1,977

|

Great reading just checked our 29, nuts were loose. Torque to 100.

Thanks again for the reminder. Your never to old and if you are, you don't know everything. Enjoy. Last edited by WHN; 08-12-2017 at 11:34 AM. |

|

|

|

|

|

#10 |

|

BANNED

Join Date: Apr 2017

Location: Sacramento

Posts: 1,262

|

The use of an assembly compound like anti seize helps to prevent the pitting and galling evident on used axles. On perfect taper applications like machine tools I agree with the clean and dry concept.

|

|

|

|

|

|

#11 |

|

Senior Member

Join Date: May 2010

Location: now Kuna, Idaho

Posts: 3,818

|

Galling is the result of movement without lubrication. If the axle nut is tight enough, there will not be any movement to cause galling.

|

|

|

|

|

|

#12 |

|

Senior Member

Join Date: May 2010

Posts: 1,343

|

I clean the taper and hub with gasolene or cellulose thinners and make sure they really are grease free . The key in ideal circumstances should not be loaded . I worked in the oilfield for a while and you have "tight" then "tight tight" then "tight tight tight" thats what you want,100 ft lbs nothing less . I do not like shims as I dont think you can get a good solid mechanical bond if you use them IMHO .

John in dark cloudy Suffolk County England . |

|

|

|

|

|

#13 |

|

Senior Member

Join Date: May 2010

Location: lafayette,la

Posts: 459

|

I put mine at 125 I think or 150 cant remember. Have fun modelAtony tony white Lafayette, LA

|

|

|

|

|

|

#14 |

|

Senior Member

Join Date: Mar 2017

Location: Connecticut Shoreline

Posts: 1,977

|

No matter what you think about keys. Please check your torque. Reason I say this.

After reading a post earlier this summer on this subject. I took a few minutes, removed rear wheels, and checked the axel nuts. You could take them off by hand. I had a complete brake job done less than 1,500 miles ago by a really well known Model T and Model A restorer. Even if done properly, they need checking. Anyway, I re-torqued to100. Everything looks to be OK. Last edited by WHN; 09-24-2017 at 02:31 PM. |

|

|

|

|

|

#15 |

|

Senior Member

Join Date: May 2010

Location: Portland OR

Posts: 6,408

|

I take mine to 90 then then turn till the slots line up. If the slots line up at 90 I use a different nut. Be sure you use the correct nuts, they are not an off the shelf garden store variety. They are hardened but I can not tell you what grade they are off the top of my head.

__________________

I know the voices aren't real but damn they have some good ideas!

|

|

|

|

|

|

#16 |

|

Senior Member

Join Date: Aug 2016

Location: Alberta

Posts: 930

|

Great thread. I am about to change the axles in my car as the right one has stripped threads. They are PROBABLY OK as the threads near the hub are OK but I have a good axle with perfect threads and a perfect keyway so I'm going to use it. The other axle has good threads but the keyway is wallowed out a bit. My plan WAS to have the keyway recut while I have the axles out. Two options, weld up the old one and recut it or just leave the old one and cut a new one on the other side. My concern is with the other thread about the broken axle and that they tend to break right where the keyway starts. Cutting a second keyway may weaken this area more increasing my chance of a broken axle and I don't know what effect welding may have on the axle. After reading tis thread, now I'm thinking perhaps not messing with it, just put in a new key, keep the nut torqued to 100lbs and go. Thoughts?

|

|

|

|

|

|

#17 |

|

Senior Member

Join Date: Jun 2015

Posts: 1,425

|

Not sure anyone answered the question from dahrens 1, taper orientation ? Bratton's says taper in toward diff. and down (in keyway). Other prior posts/ threads may differ.

|

|

|

|

|

|

#18 |

|

Senior Member

Join Date: May 2010

Location: Mpls, MN

Posts: 27,582

|

Yes, the taper faces down and in.

|

|

|

|

|

|

#19 |

|

Senior Member

Join Date: Jun 2015

Posts: 1,425

|

Glad this thread was posted; pulled rear wheels to do some adjustments and found one axle nut loose !! was able to get to 95'# and align cotter. Also, powder coated wheels need periodic checking to 60'#, even with paint removal at nuts, etc.

|

|

|

|

|

|

#20 |

|

Member

Join Date: May 2010

Location: Carlsbad, CA

Posts: 76

|

Great thread here. After reading I removed the rear wheels and checked the torque on mine and only had 50 # or so on the right side and 75 # on the drivers side. Did a total brake restoration 5 yrs and 1500 miles ago with new parts throughout.

Disassembled to check the condition of the brakes, etc. and noticed the keys were worn. New parts on order. Definitely will be checking torque frequently from now on. Thanks for all the information here on the Barn! |

|

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 07:48 PM.

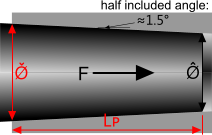

Fig 2. Self-Holding Tapers

Fig 2. Self-Holding Tapers

Hybrid Mode

Hybrid Mode