|

|

|

|

#1 |

|

Senior Member

Join Date: May 2010

Location: So Cal

Posts: 9,359

|

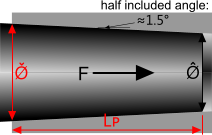

Self-Holding Tapers

Fig 2. Self-Holding Tapers Fig 2. Self-Holding TapersA special case for the beneficial use of friction is 'self-holding' Tapers (Fig 2) for easy machine/equipment component assembly and disassembly such as drill chucks and lathe tail-stock accessories. A self-holding 'Taper' is an accurately machined tapering shaft and mating sleeve (both of which are dry and clean) that lock together using the coefficient of friction between the two surfaces (shaft and sleeve) and an assembly force (F). If the Taper is machined correctly, the same force (F) will be needed to separate the shaft and sleeve. If the angle of the Taper is 'exactly right', the shaft or sleeve will be capable of driving the other with no additional assistance for light duty applications and yet part easily with no resultant damage to either of the mating surfaces. It is important to remember that a plain self-holding taper is only capable of transmitting a force achievable from 'frictional' grip and is thereby limited in its driving capacity. For heavy duty applications the taper is usually provided with a key, the frictional grip providing the holding capacity only. |

|

|

|

|

|

#2 | |

|

Senior Member

Join Date: May 2010

Location: South California

Posts: 6,190

|

Quote:

Very good info for all who care to know details of this matter, and not rely on old tales and hearsay that has been passed on. NOW, maybe this will be passed on and help those with axle problems...but do not know WHY ! Proper amount of Model A axle nut torque has not been discussed, so far. Just what is the proper amount ? When the number of ft lbs is told, the number is NOT believed by most...why ? Without new axles/nuts, Model A owners say....oh, that's not right, is tooo much, I just torque them till their tight  ! !Again, if not lapped right, and not torqued right....nothing is right according to the excellent info that has been provided above. |

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#3 |

|

Senior Member

Join Date: Jul 2012

Location: Venice, FL

Posts: 667

|

Bob C,

Thanks for the explanation on self holding tapers. The model 'A' axle tapers and hubs, (sleeves) I've seen are everything but accurate and honed tapers. Mine are pitted warn and gouged. And in many cases not torqued to 100 plus pounds. Thanks for mentioning the use for light and heavy load uses for keyed and non-keyed applications. Al Leach |

|

|

|

|

|

#4 | |

|

BANNED

Join Date: May 2010

Location: Wa.

Posts: 5,423

|

Quote:

Read and understand the LAST paragraph in the above BobC's post #17. Bt lapping the hub to the axle and getting a 100% surface, you can run WITHOUT a key in a STOCK model A application. It is NOT a heavy duty application. HOWEVER, it is near to impossible to get 100% surface on an axle and hub with machined surfaces that has been run/abused, corroded and pitted. |

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 01:37 AM.

Hybrid Mode

Hybrid Mode