|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

Thread Tools | Display Modes |

|

|

#21 |

|

Senior Member

Join Date: May 2010

Location: Spokane, WA.

Posts: 496

|

I am aware that it's an FHP. I'm not sure why that would preclude it from use on a Model A. In the past the belts I bought from Model A vendors didn't last long so I went to NAPA and the first belt they sold me was a cogged belt that scritched. So I did some detective work and found that the "fractional horsepower belts" fit perfectly. I suppose there is an implication that they weren't designed to turn the kind of RPMs that car engines normally turn,(Model A's turn a lot fewer RPMs than modern cars) but I've been running them on 2 of my A's for a couple years now with no problems. I put on about 5,000 miles per year and both of these A's will do over 70 MPH. On long tours (500-600 miles) we generally average about 55 MPH. My 3rd A is a points car and doesn't get many miles so I've never worn out the original belt. Thanks for you comments, but please explain why an FHP belt is not suitable.

Last edited by Larry Seemann; 06-07-2010 at 06:10 PM. |

|

|

|

|

|

#22 |

|

Senior Member

Join Date: May 2010

Location: La Verne, Ca.

Posts: 831

|

Try a Dayco FHP V-Belt P/N 5L440. Exact fit and was in stock at my local parts house. Not Kragen, Auto Zone or the like. My 2 cents. Good luck

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#23 |

|

Senior Member

Join Date: May 2010

Location: Rock Hill, S.C.

Posts: 985

|

If the fan belt and the pulley do not share the exact taper, and the outer edge of the belt is where it is running on the edge of the aluminum fan pulley, it will get stressed out in that area quite quickly, and look like your picture. Looking forward to seeing you and Val in French Lick. I want to get a look at your car.

__________________

Uncle Bud says "too soon old, too late smart!" |

|

|

|

|

|

#24 |

|

Senior Member

Join Date: May 2010

Location: ca.

Posts: 2,522

|

must be a batch of belts from china .................. steve

__________________

V4f |

|

|

|

|

|

#25 | |

|

Senior Member

Join Date: May 2010

Location: The sticks of east Texas

Posts: 474

|

Quote:

Tighten the belt so that it is tight. No more than 1/2"-3/4" deflection. Get a belt from NAPA. I also have had one of the "bad batch" that lasted less than 100 miles. The NAPA belt is still going strong. |

|

|

|

|

|

|

#26 |

|

Senior Member

Join Date: May 2010

Location: Mpls, MN

Posts: 27,582

|

Sponsored Links (Register now to hide all advertisements)

I run an original powerhouse and 2 blade fan and I can easily flex my belt 1 1/2" to 2" midway from the generator to the fan. Most people would think it's too loose, but it isn't, as it doesn't slip with the lights on when I rev the engine. Last edited by Tom Wesenberg; 06-08-2010 at 07:37 AM. |

|

|

|

|

|

#27 |

|

Senior Member

|

Mine doesn't ride as high in the pulley as yours.

__________________

What's right about America is that although we have a mess of problems, we have great capacity - intellect and resources - to do some thing about them. - Henry Ford II |

|

|

|

|

|

#28 |

|

Member

Join Date: May 2010

Location: Charleston, SC

Posts: 59

|

Yep, generators can be looser, but alts need to be tight. Which can be a problem in flathead motors if not properly rebuilt with upgraded bearings because the exta tension can cause premature wear on engine bearings. Powermaster's website touches on this somewhere (I looked but couldn't find it). Relating more to the topic, if you have loose belts, they can be fray, but more likely will be thrown easily.

|

|

|

|

|

|

#29 |

|

Senior Member

Join Date: May 2010

Location: New York

Posts: 158

|

Only buy a automotive belt. Small engine and low power belts have a different angle on the Vee's.

My belt has been on for 3 years with no problem. I have about 5/8" deflection.

__________________

"Some Talk the Walk while others Walk the Walk" Last edited by Bob A.; 08-04-2010 at 09:30 AM. |

|

|

|

|

|

#30 |

|

Senior Member

Join Date: May 2010

Location: ASTON, PA.

Posts: 725

|

Mark,

I had a blindback fordor in my shop that had the same problem, first I alligned the alt. to crank pully, then to water pump. Same problem I removed the waterpump and found the impeller was not pinned and when the r.p.m. went up the waterpump shaft would move toward the radiator. Changed the waterpump and fan blade problem solved , hope this helps. mike |

|

|

|

|

|

#31 |

|

Senior Member

Join Date: May 2010

Location: ASTON, PA.

Posts: 725

|

Mark,

it also liiks like your alt is not alligned with the w/pump |

|

|

|

|

|

#32 |

|

Senior Member

Join Date: May 2010

Location: Ontario, Canada

Posts: 1,470

|

When I performed a search for Model A Ford belts on the Napa site, it gave the following: Product Description Line code UNR Part number 2520426 Description Belt - Accessory Drive Attribute Product Features:Specifically Designed For Heavy-Duty Truck, Bus & Off-Road Equipment Applications. Absorbs Normal Shock Loads w/o Damage To Belt. Special Tensile Cords Give High Stretch Resistance.,Top Width (in):.625",Top Width (mm):16 mm,Outside Circumference (in):42.99",Outside Circumference (mm):1092 mm,Angle Degree:36,Notched Belt:Yes,Section:S Note that it says it is a "Notched Belt" ???? |

|

|

|

|

|

#33 |

|

Senior Member

Join Date: May 2010

Location: Mpls, MN

Posts: 27,582

|

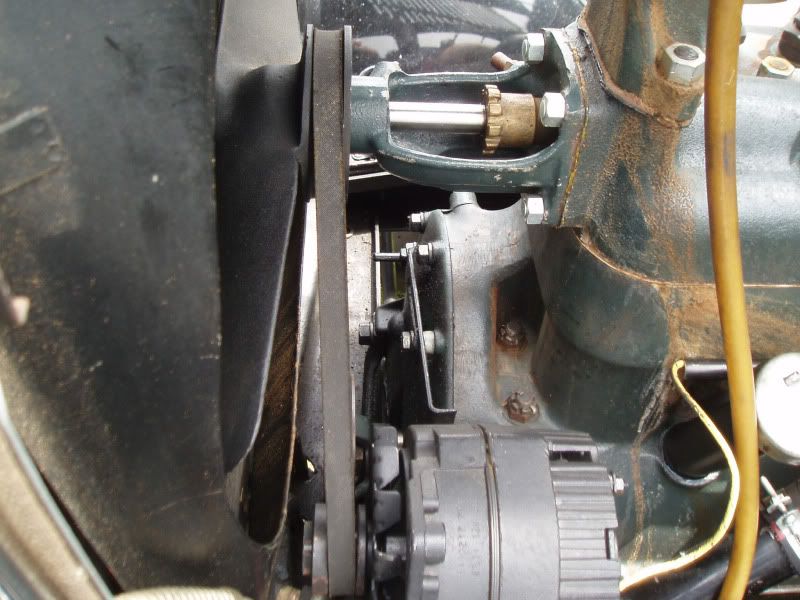

I didn't see belt misalignment in Mark's pictures of his engine, but this picture of a different engine shows belt misalignment I often see when people use alternators. Also grab your aluminum fan and try to rock it on the shaft to make sure it's well seated to the taper. |

|

|

|

|

|

#34 |

|

Senior Member

Join Date: May 2010

Posts: 107

|

I had the same problem with a 60amp alternator and I couldn't tighten the belt tight enough to keep it from slipping on the alternator. After trying many things and having many failures, I purchased a 3 inch pulley for the alternator from the local rebuild shop. This gave me a lot more belt in the alternator pulley and the larger pulley turned the alternator armiture easier than the small 2 inch. I am using the B-41 belt for over 3,000 miles now and don't need to tighten it down to banjo string tightness.

|

|

|

|

|

|

#35 |

|

Senior Member

Join Date: May 2010

Location: Connecticut

Posts: 272

|

Hi Mark, Its difficult to see in the picture, but I believe I see a misalignment between the crank pulley and the waterpump pulley. Put a straightedge on the crank pulley and line it up with the waterpump pulley. Does the belt run parallel with the line of the crank pulley? Or at an angle? The alternator side looks good in your picture, but you should check that as well. If they are not in alignment, then you will have to make choices as to how you are going to correct the geometry of the crank, waterpump, and alternator pulleys. Im my own car ('29) I had to shorten the waterpump shaft to move the wp pulley back, AND move the generator forward in order to get complete compliance of the three pulleys. Good Luck!

|

|

|

|

|

|

#36 |

|

Senior Member

Join Date: May 2010

Location: Sarasota Florida

Posts: 604

|

I just went out and look at the part # on my belt. The one I have is not a gates like I thought It is a Dayco (its notch/clogged) and has 3 # on it 1st#( 23425) 2nd# (16A1080) 3rd# (1295). I don't know why I thought I had a Gates.

|

|

|

|

|

|

#37 |

|

BANNED

Join Date: May 2010

Location: Gothenburg Nebraska Just off I-80

Posts: 4,893

|

The older Dayco belt I have is a 5L430. I seem to recall this one being alittle tight, but had alot of room for stretch amd adjustment. Not sure how it will work with your set up. Was working good with my original fan and generator. The one I removed was a 4L440 and it was at the end of its adjustment, but was on the engine when I bought it. Rod

__________________

Do the RIGHT thing - Support the H.A.M.B. Alliance!!!! |

|

|

|

|

|

#38 |

|

Senior Member

Join Date: May 2010

Location: Cincinnati, Ohio

Posts: 798

|

I can understand not wanting to buy NAPA'S cogged belt, especially if you are a "fine point guy." However, Bratton's carries the correct Gates belt that fits the Model A.

Bratton's number is their specific catalog number, but the number that is on the belt is G 07. That's the number on my spare, but it may have changed. Jack

__________________

Cincinnati, Ohio |

|

|

|

|

|

#39 | |

|

Senior Member

|

Quote:

G07 you are saying is the GATES belt number from brattons??

__________________

Mark Maron Ill., Region MARC & MAFCA MARC JSC Member MAFFI Trustee National Facebook Admin. https://www.facebook.com/groups/MARC.group/ A7191-Sport Coupe 29 Roadster 29-Town Sedan 29-Original Special Coupe |

|

|

|

|

|

|

#40 |

|

Junior Member

Join Date: May 2010

Location: Orangevale, Calif

Posts: 15

|

I had the same problem last year. The small dia alt pulley has a wide grove but was not deep enough so the belt was riding on the inside of the belt. My belts would fray on the inside make noise and come apart in a short time. I replaced the alt pulley with the two peace 2 1/4 in dia type it has a deeper grove so the belt rides on the side not the inside so far so good. Iím now using a stock 43 in belt with less tension and it still looks good after a year now. Before changing the pulley I tried to slip a thin paper gauge under the belt to see it had any clearance. It was riding on the inside of the belt slipping and overheating then failing. Hope this helps.

Mike with a 1928 Tudor |

|

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 10:20 PM.

Linear Mode

Linear Mode