|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

Thread Tools | Display Modes |

|

|

#21 |

|

Senior Member

Join Date: May 2010

Location: Rock Hill, S.C.

Posts: 985

|

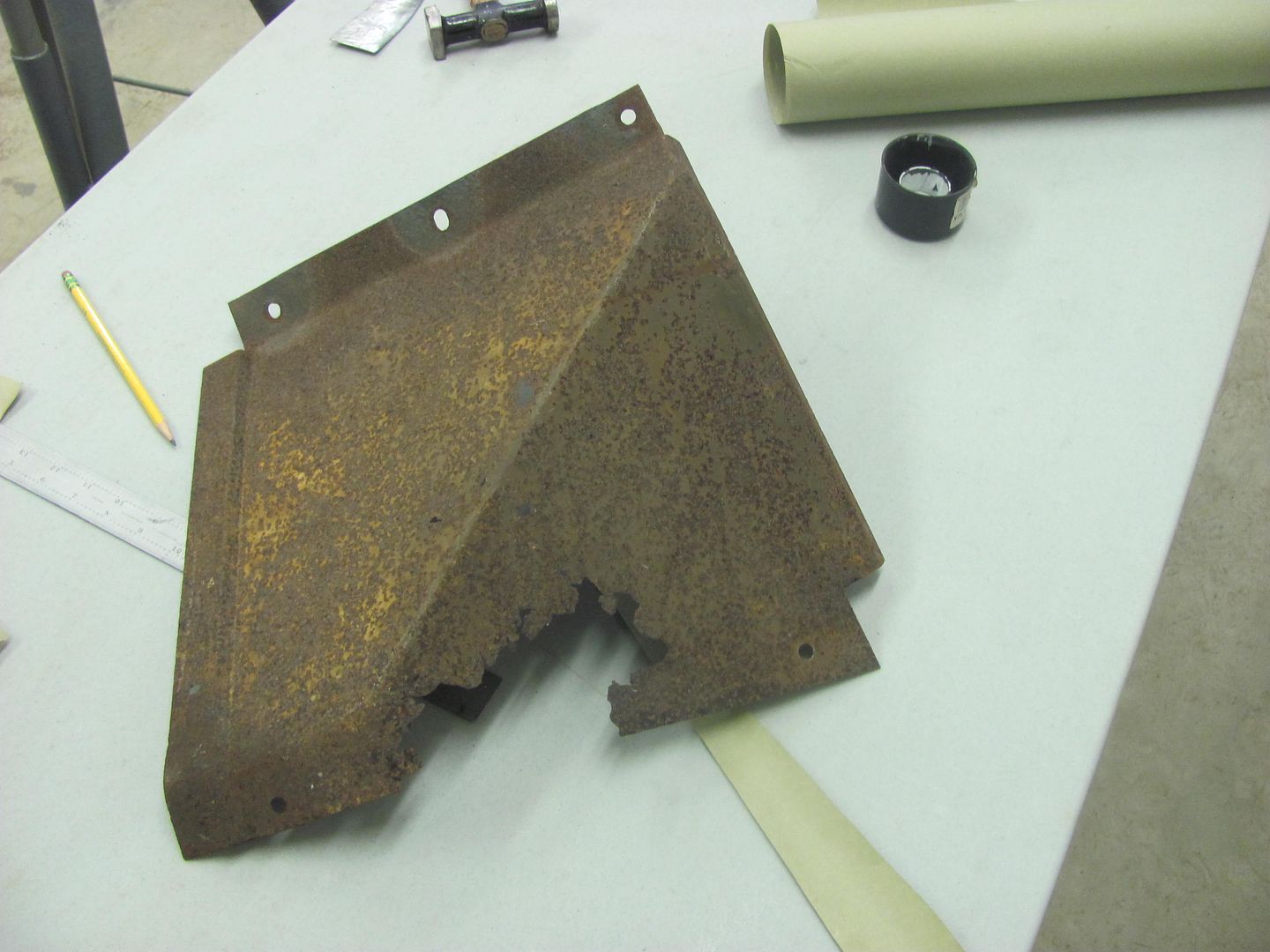

Here are a few more pictures from the class that were sent to me by one of the attendees. On the Model A fender, it required a patch about 6" wide by 8" tall right at the cross brace mounting holes and ran thru the crease. Peter cut and preformed the repair patch in a manner that fit the opening exactly and used the gas welding torch to tack the panel in place. He was very careful to explain the reasoning for the slow initial tacking method and it's effect on the finished repair. When explained by an old world craftsman, it becomes apparent that the more common use of MIG and TIG is an inferior approach to sheet metal when compared to the historical method of gas welding. He explained all the common reasons normally heard about why they can be used, but when explained by some one well versed in ALL types of welding, it becomes quite apparent that MIG and TIG are used to make the repair quicker, but the long term results will suffer. I know this first hand as the Pickup that I restored a few years ago was MIG and some TIG welding done by the paint guy has started to crack. Gas welding will leave the repair in identical condition as the parent metal. Testing with a Rockwell hardness tester will confirm the degree of brittleness and lack of malleability adjacent to the weld on MIG and TIG joints.

Peter completed the repair using no English wheel or other piece of equipment. The weld was so nice that there was no grinding required. He buffed the repair area with a large scotchbright disc and hand finished the repair with a sharp 'corking' tool. The pictures of the 'fire' must have been intended to test my heart rate. Peter noticed a slight flare at the side of the tail section and rapidly began to anneal that section and the fix it with one of his own designed slapper. It scared the crap out of me seeing him aim a torch at it, but it turned out great, and we all learned a good lesson. PetersClass4 001.jpg PetersClass4 002.jpg photo 1.jpg photo 2.jpg

__________________

Uncle Bud says "too soon old, too late smart!" |

|

|

|

|

|

#22 |

|

Senior Member

Join Date: May 2010

Location: Fort Worth, Texas

Posts: 1,055

|

Hey Will, I'd also like to be put back on the list for next years class. That would be great if we could get the same group together again.

__________________

Cowtown A's |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#23 |

|

Senior Member

Join Date: May 2010

Location: Mpls, MN

Posts: 27,582

|

I can understand MIG leaving the weld too hard, but I thought TIG would be similar to gas welding.

|

|

|

|

|

|

#24 |

|

Senior Member

Join Date: May 2010

Location: Rock Hill, S.C.

Posts: 985

|

Tom, it my understanding that the negative about both the TIG and the Mig, is the rapid heat build up and the rapid cooling, leaving a narrower heat affected zone. Any type of welding that has a wider HAZ will result in a longer cooling time which I feel results in a 'self-annealing' process, resulting in a more ductile weld area. My biggest concern with the TIG process is that the rapid cooling time traps bubbles that are created when the weld is liquid. This can be readily seen if you ever saw a TIG weld in half. It is also somewhat easier to fusion weld when gas welding and this results in less weld buildup requiring less post-weld grinding/heat.

Most folks have reasons for choosing their style of welding, but after the recent class with Peter, I am more and more comfortable using gas welding for the common #19 gage steel repairs on the Model A type cars, and using the gas welding of the aluminum on the current Bugatti fender project and similar projects.

__________________

Uncle Bud says "too soon old, too late smart!" Last edited by RockHillWill; 10-01-2015 at 10:32 AM. |

|

|

|

|

|

#25 |

|

Senior Member

Join Date: May 2010

Location: Rock Hill, S.C.

Posts: 985

|

Logan, I was hoping that I could include you as well for the same reason. I already have you on the priority list for the next class(es).

__________________

Uncle Bud says "too soon old, too late smart!" |

|

|

|

|

|

#26 |

|

Senior Member

Join Date: May 2010

Location: Rock Hill, S.C.

Posts: 985

|

Sponsored Links (Register now to hide all advertisements)

I am recording them in the order in which they are received, giving priority to those that attended this years class. I have been pleasantly surprised at how many folks have had an interest in the original form of metal shaping. Logan: I have found and set aside your items.

__________________

Uncle Bud says "too soon old, too late smart!" |

|

|

|

|

|

#27 |

|

Senior Member

Join Date: Nov 2012

Location: West Berkshire, United Kingdom

Posts: 368

|

Thanks for the post and the pictures, very jealous

__________________

Kevin Flood West Berkshire UK Member MAFCGB, VHRA, SAH, Brooklands Trust Sporadic progress on My 1929 Sport Coupe can be found here along with my blog  http://automotiveamerican.com/ |

|

|

|

|

|

#28 |

|

Junior Member

Join Date: May 2010

Posts: 17

|

Will, if I could impose, may as well keep these together in one thread...

Here are some of the pictures from the Tommasini class in MD.. Here are some of the highlights of Thursday's class.... Peter shows how to prepare a stump for shrinking....     Discussing weld location in panel forming....   Using magnets to hold a paper pattern for layout....      Wheeling, tuck shrinking and annealing aluminum sheet...

|

|

|

|

|

|

#29 |

|

Junior Member

Join Date: May 2010

Posts: 17

|

Capturing the tuck and shrinking on aluminum sheet

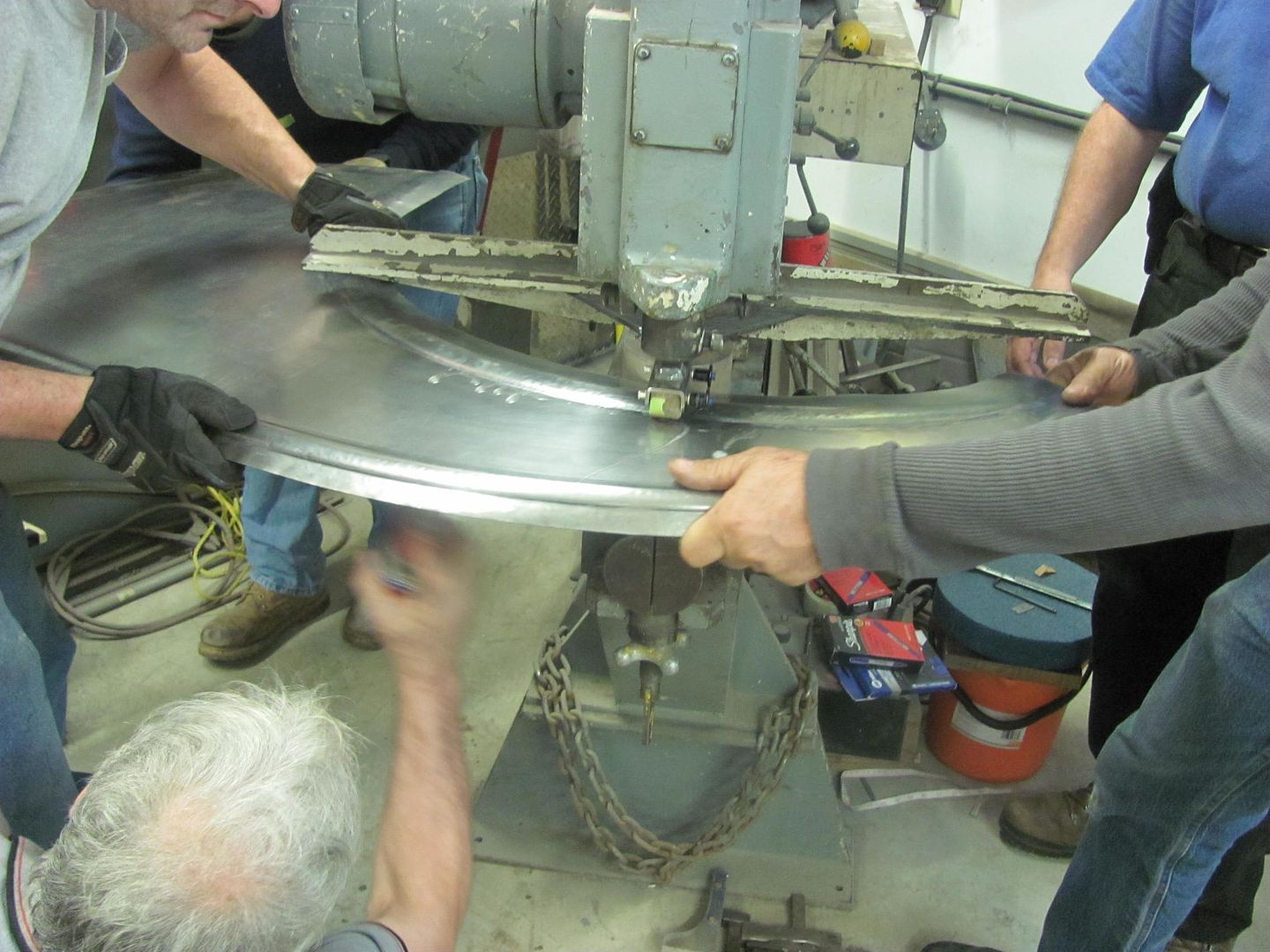

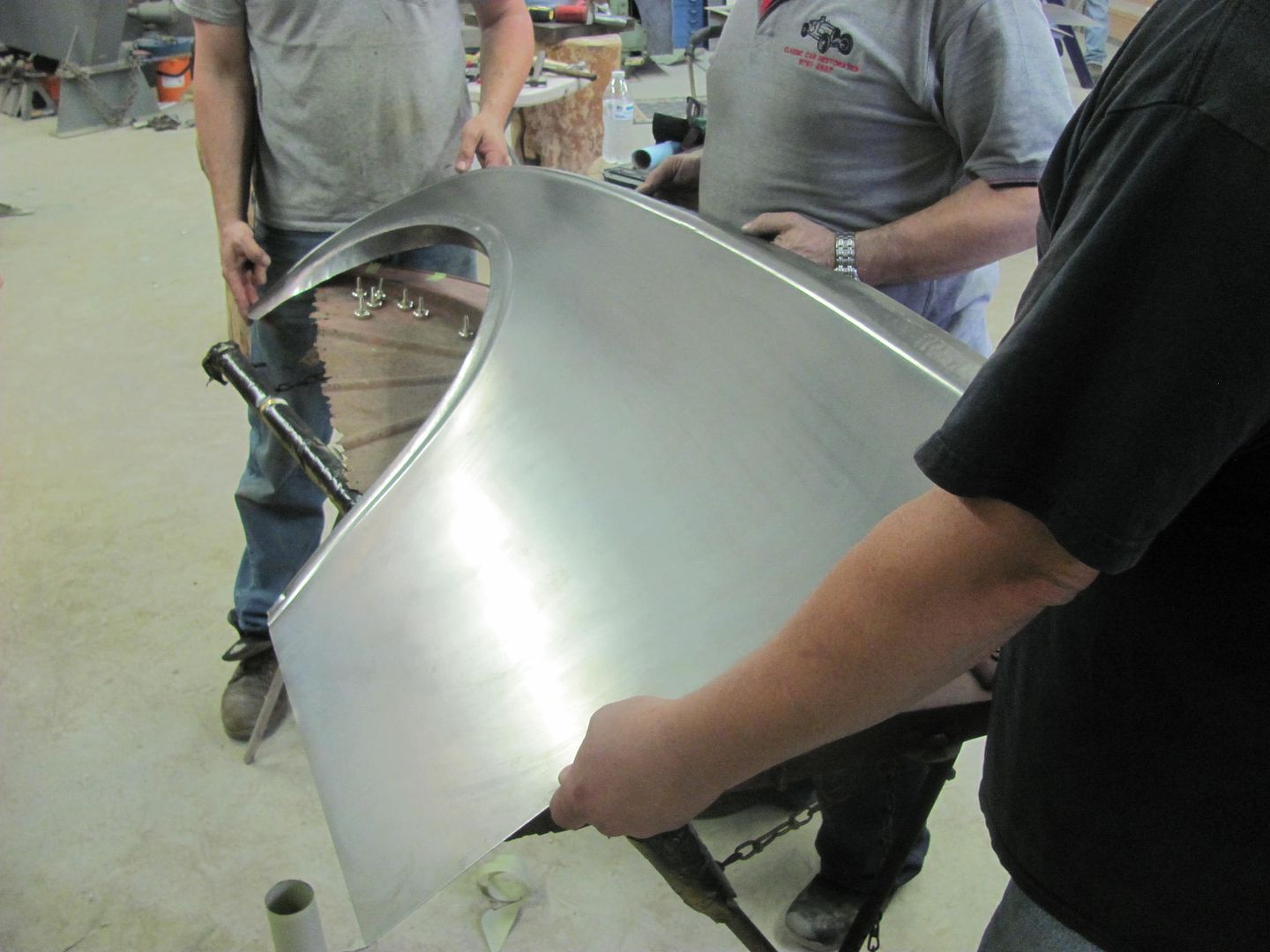

Blocking and wheeling our 19 gauge steel fender panel...   Forming the rear corner for a Model A..     Blocking on the sand bags and shrinking on the stump....     Wheeling....

|

|

|

|

|

|

#30 |

|

Junior Member

Join Date: May 2010

Posts: 17

|

Here's some of today's class projects.

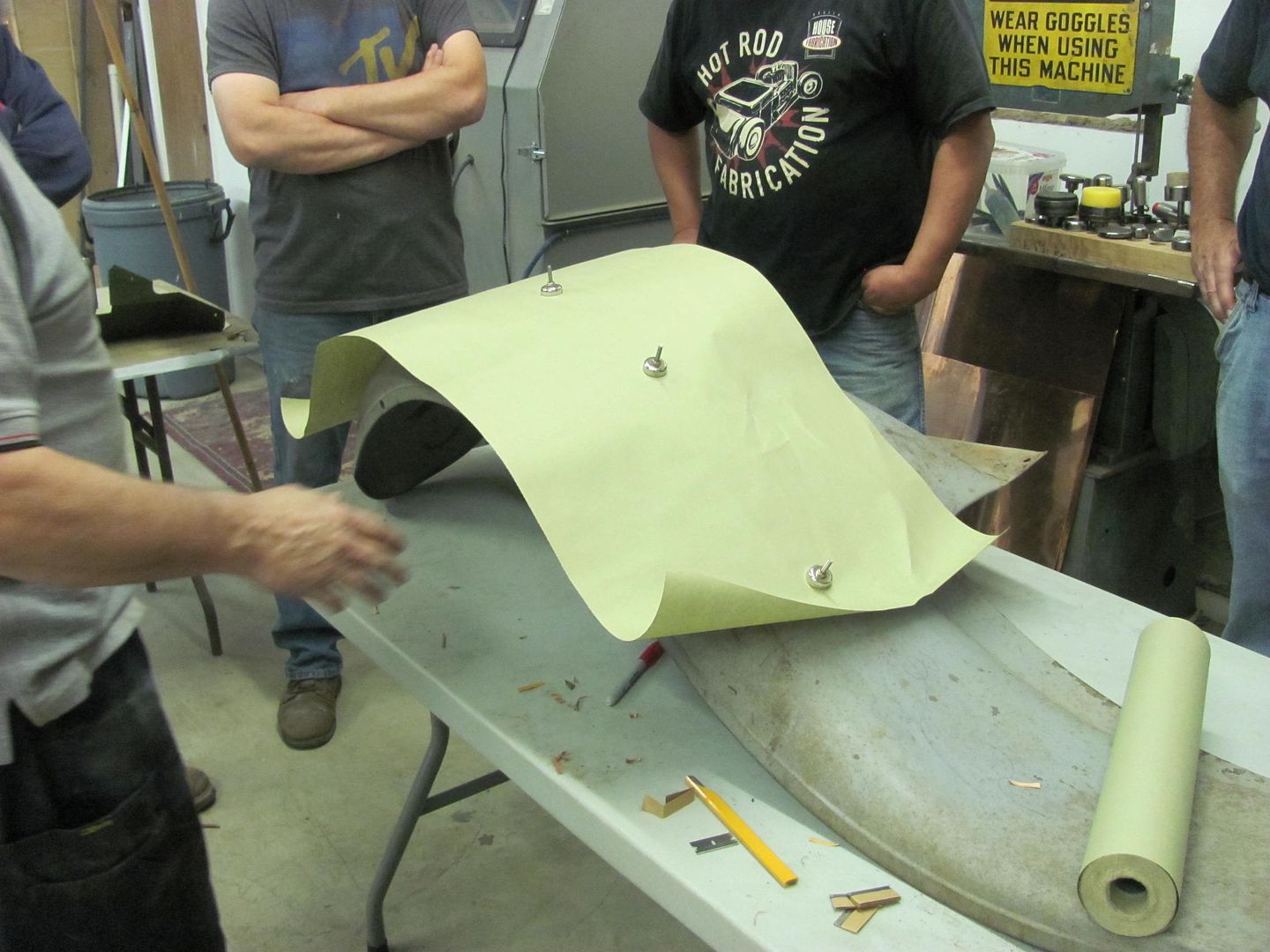

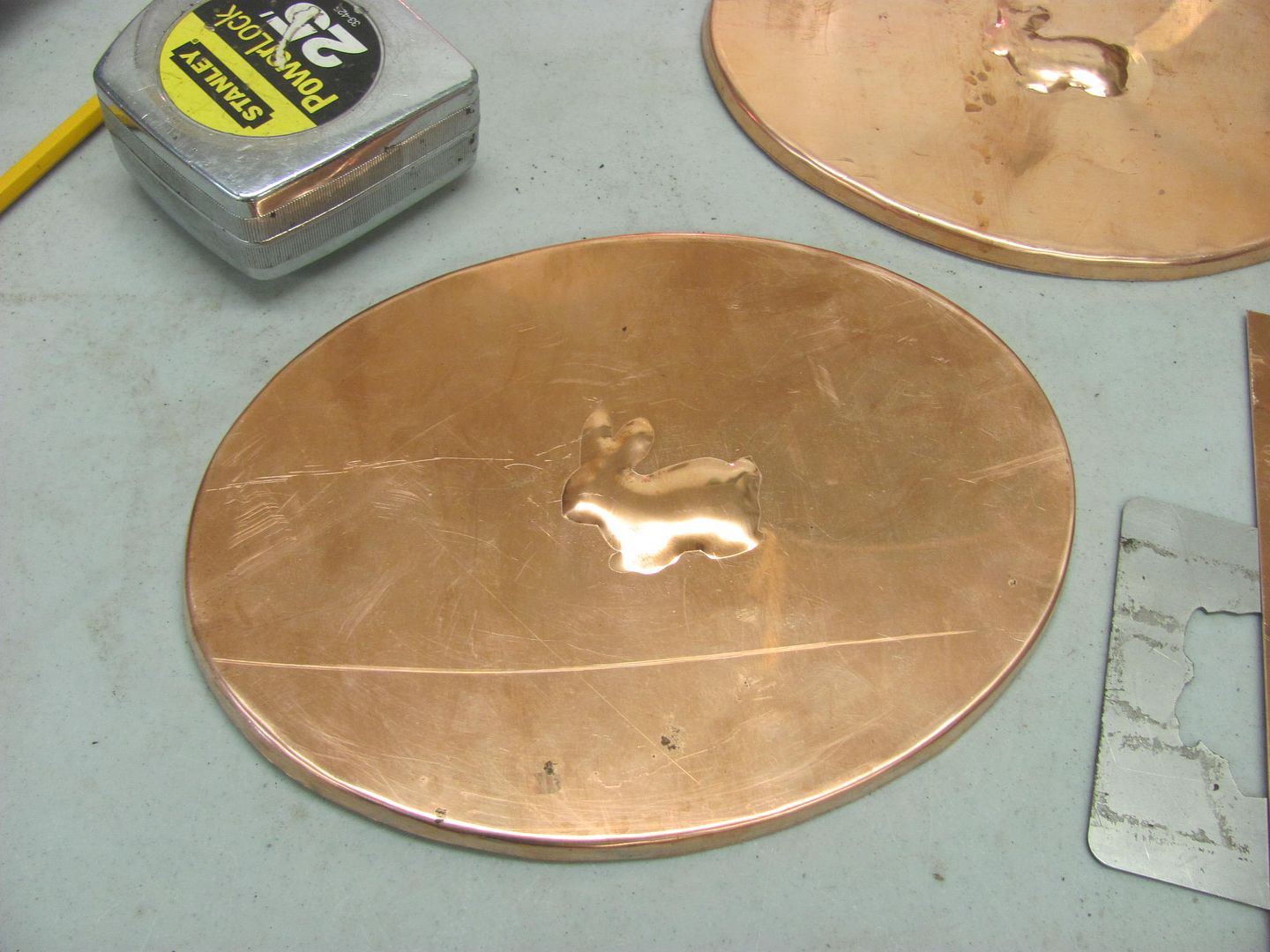

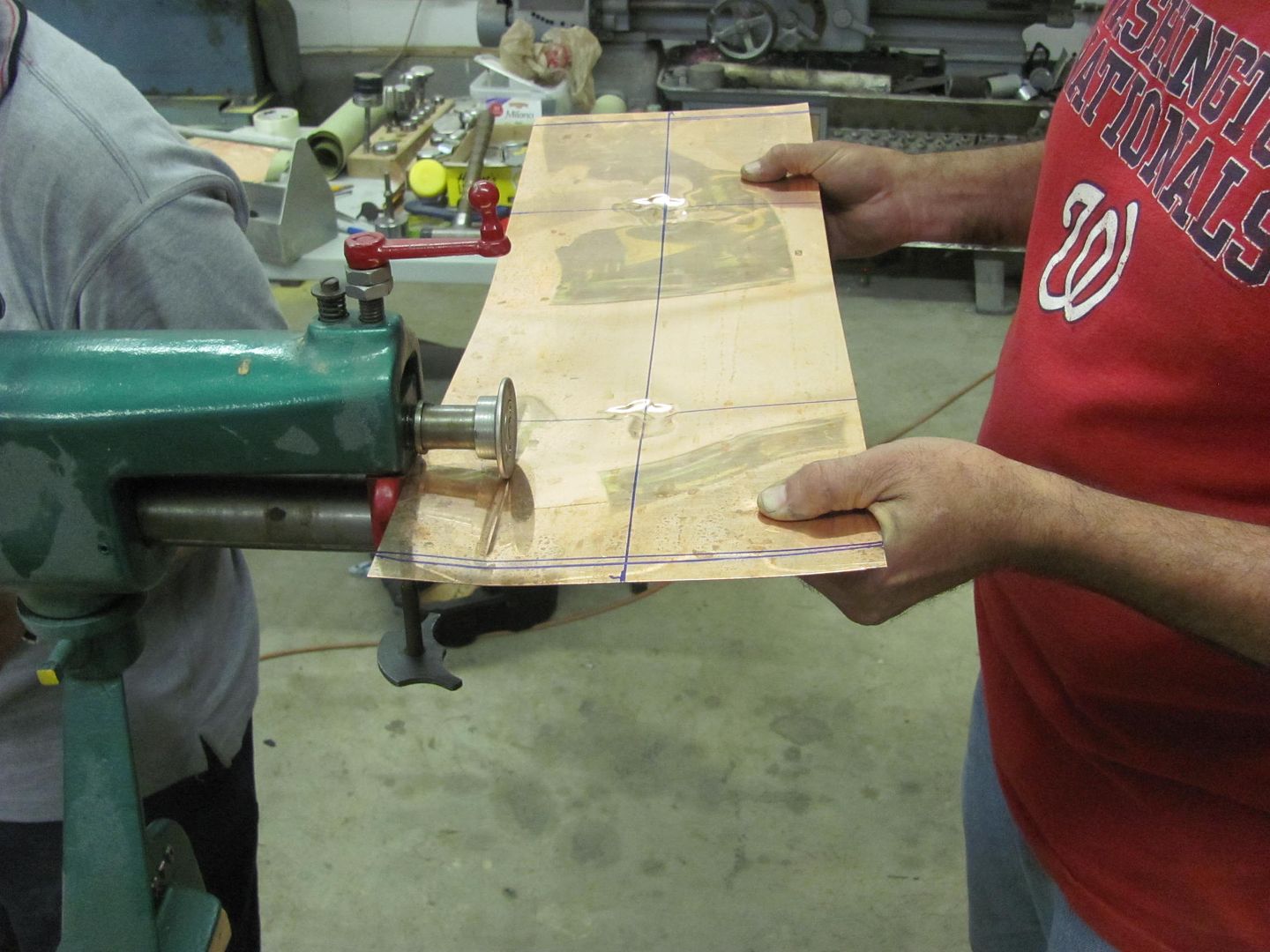

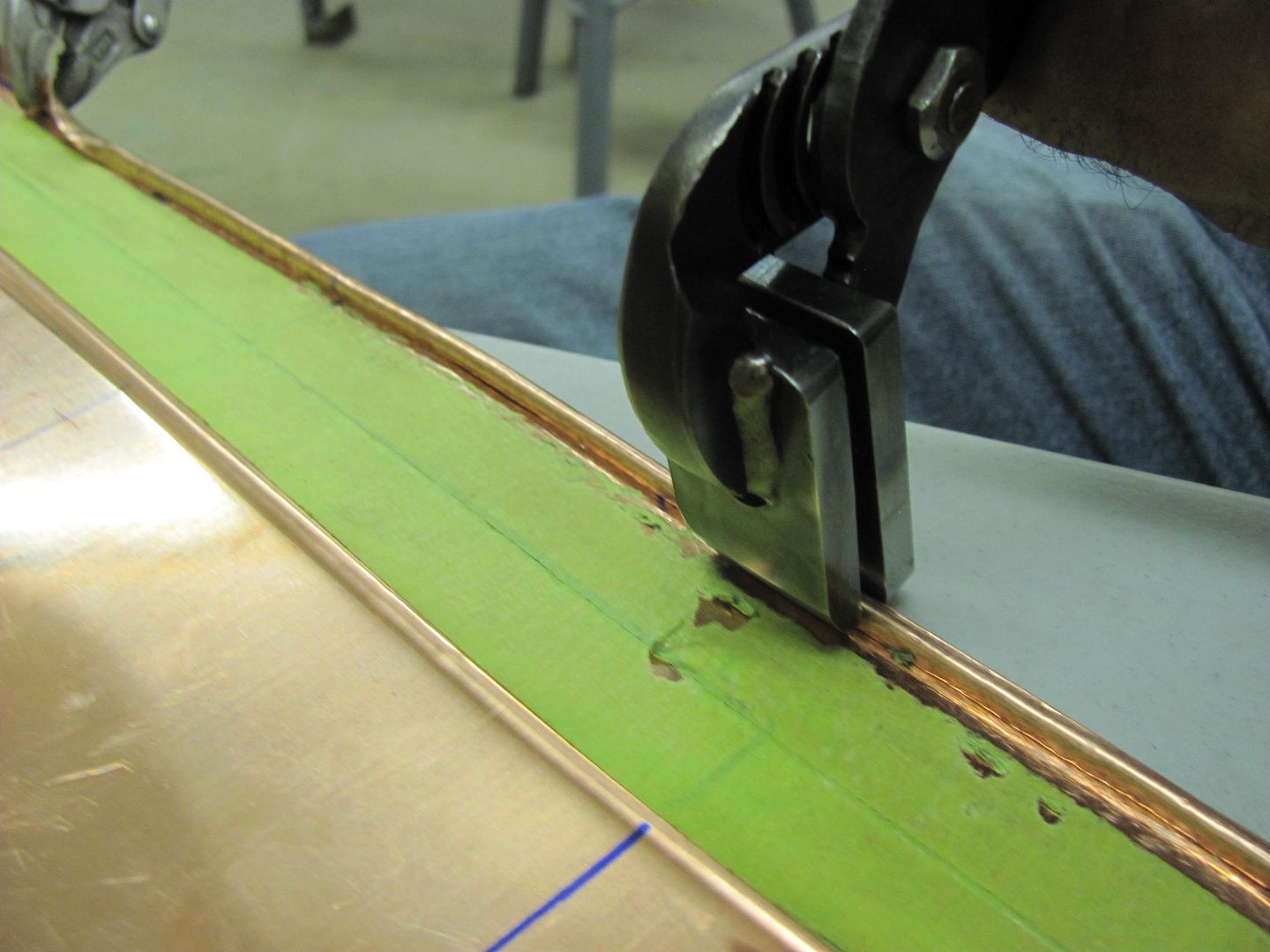

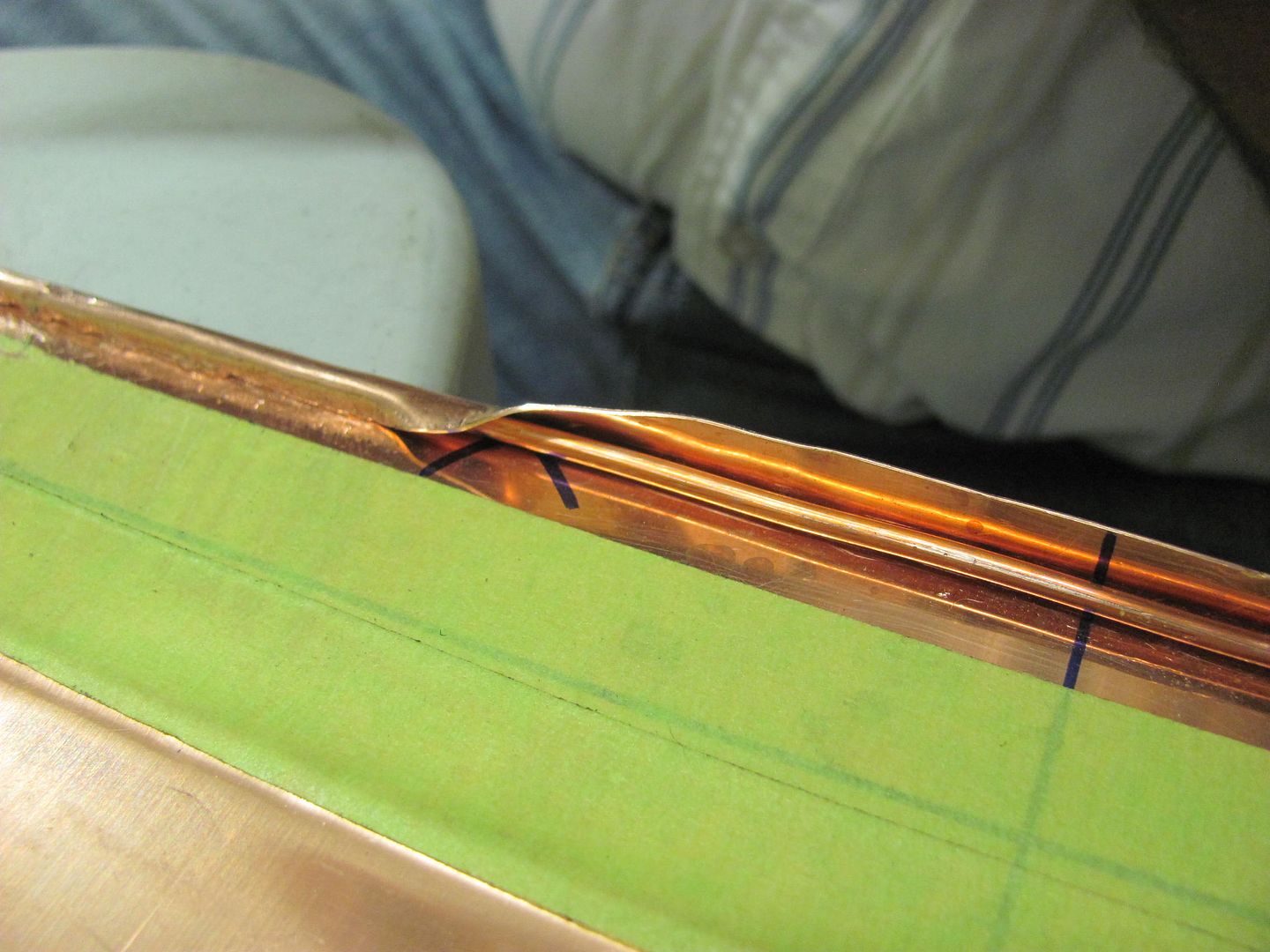

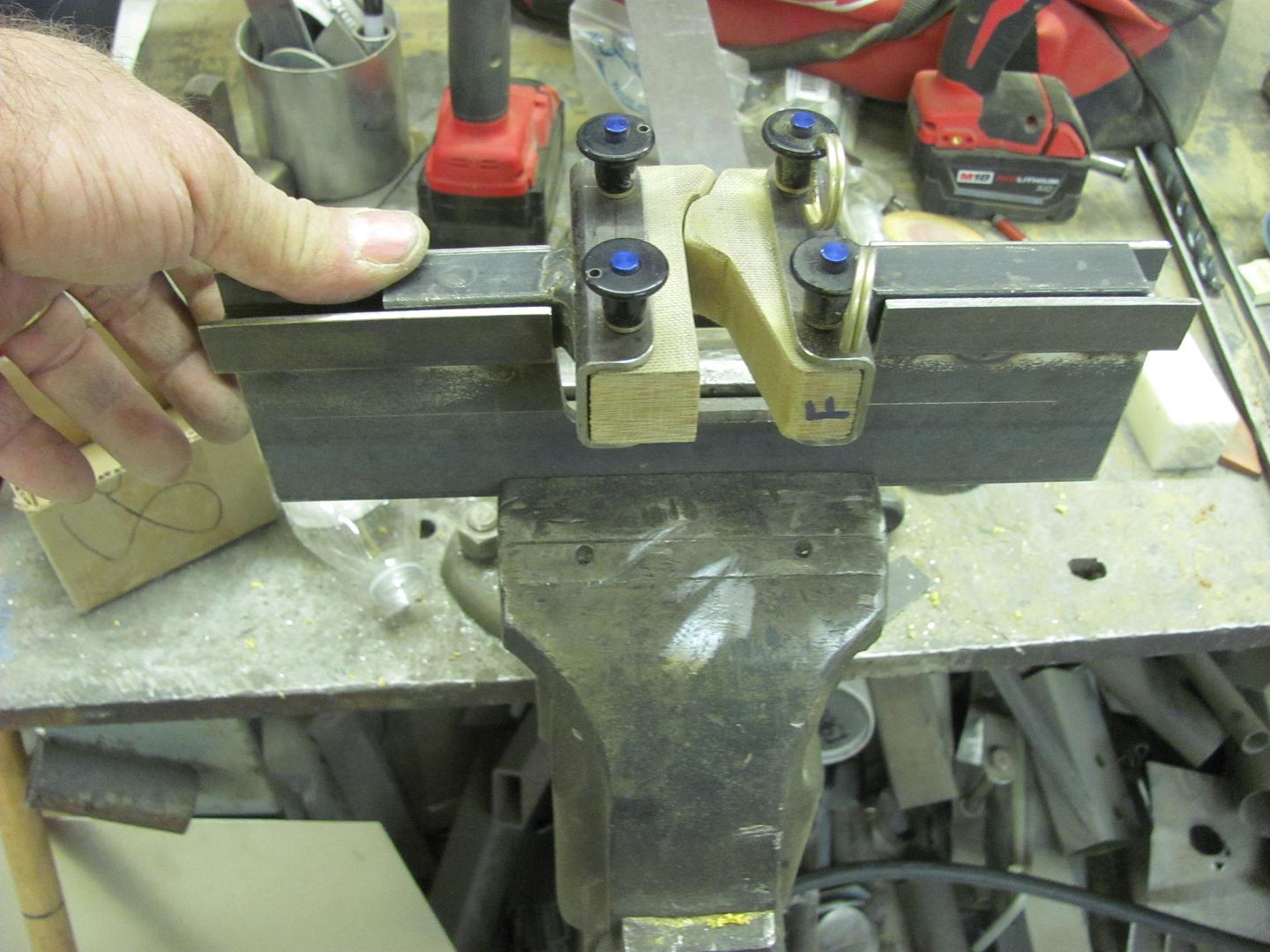

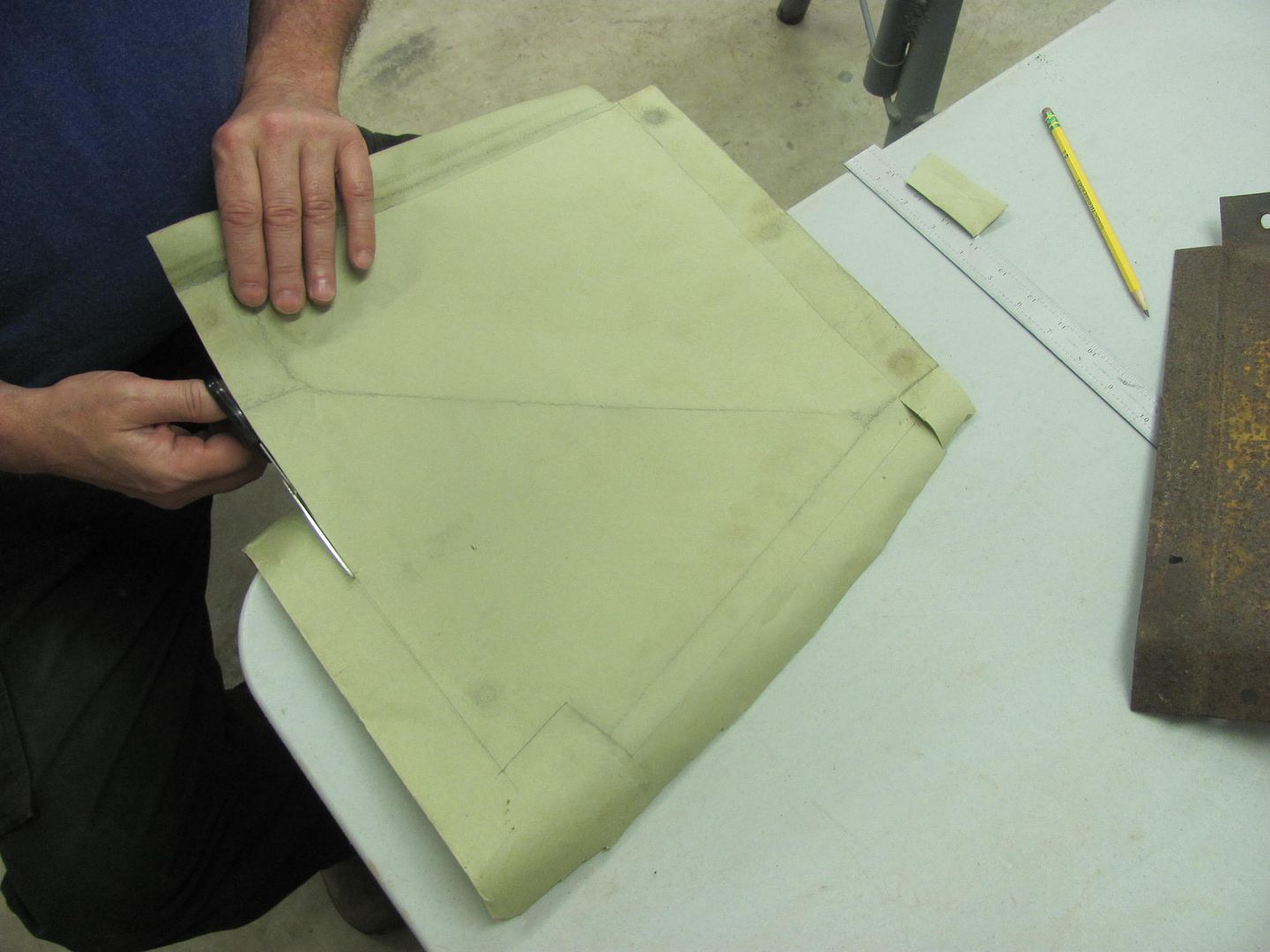

The start of a scooter fender...  Test fit of a fender panel...  Copper work, trash can taking shape...       Paper pattern on a roadster quarter panel....    Using the blocking hammer to pre-stretch  Making a pattern for the dies

|

|

|

|

|

|

#31 |

|

Junior Member

Join Date: May 2010

Posts: 17

|

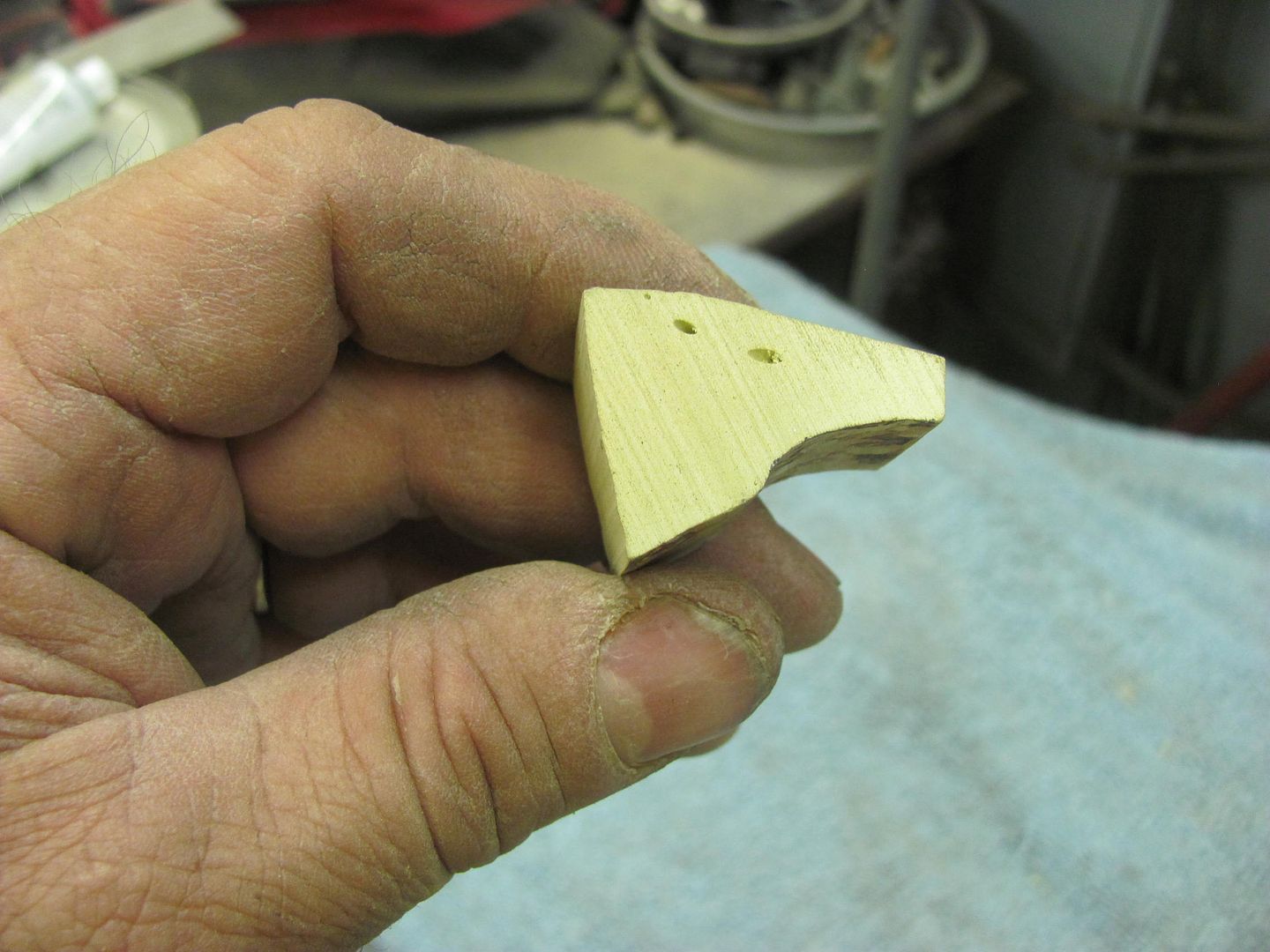

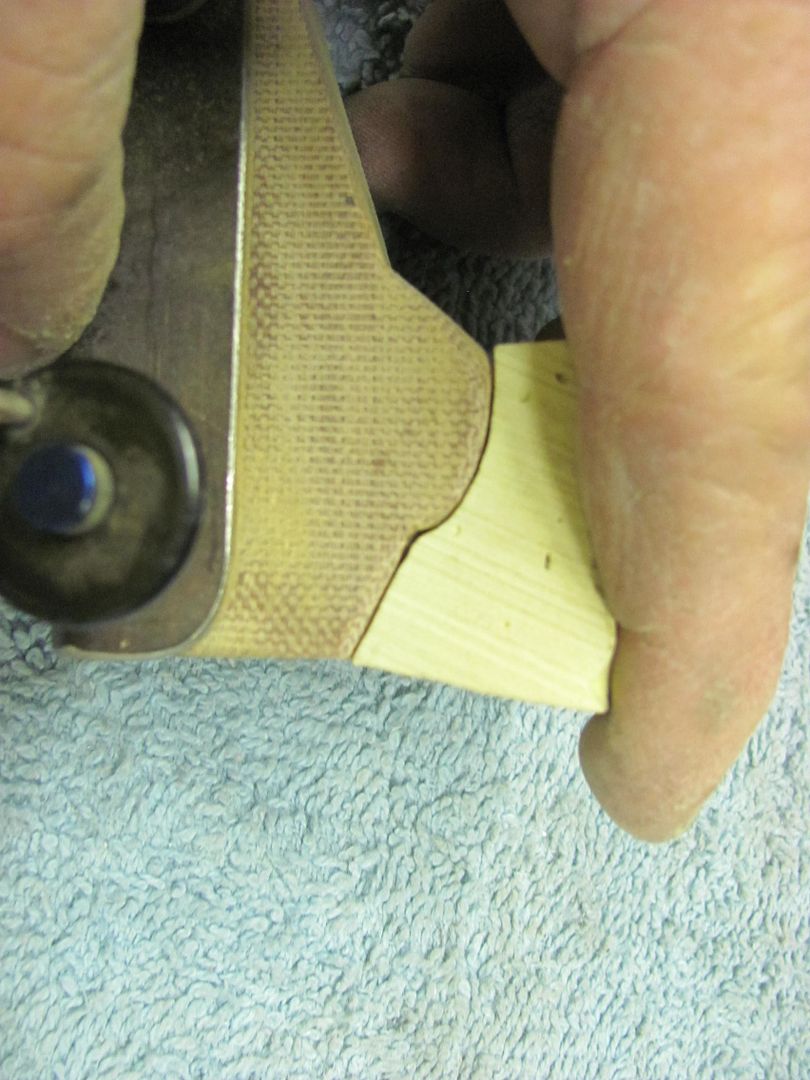

Making a pattern of luan board for a divider offset in trimming the top edge..

What happens when a metal shaper gets around wood products...   Trimming and filing up the top edge....  On to the Lennox....

|

|

|

|

|

|

#32 |

|

Senior Member

Join Date: May 2010

Location: Rock Hill, S.C.

Posts: 985

|

Richard, make yourself at home here. It is good to share metal shaping knowledge from every available source. There are many talented folks that visit this site. Several of us here at the Rock Hill class made notes on Peters method of 'finishing' the top of a stump, but looking at your photos clears up more about the shape and contour size. You have a very impressive assortment of tools and equipment in your shop, and I hope those in attendance appreciate your opening up your shop for their personal use. Keep the pictures coming, especially of the Model A parts being made. I have made an assortment of hammer forms for some of the interior reinforcement panels for the fenders, and will gather some pics today, if possible.

__________________

Uncle Bud says "too soon old, too late smart!" |

|

|

|

|

|

#33 |

|

Junior Member

Join Date: May 2010

Posts: 17

|

Project updates for todays class:

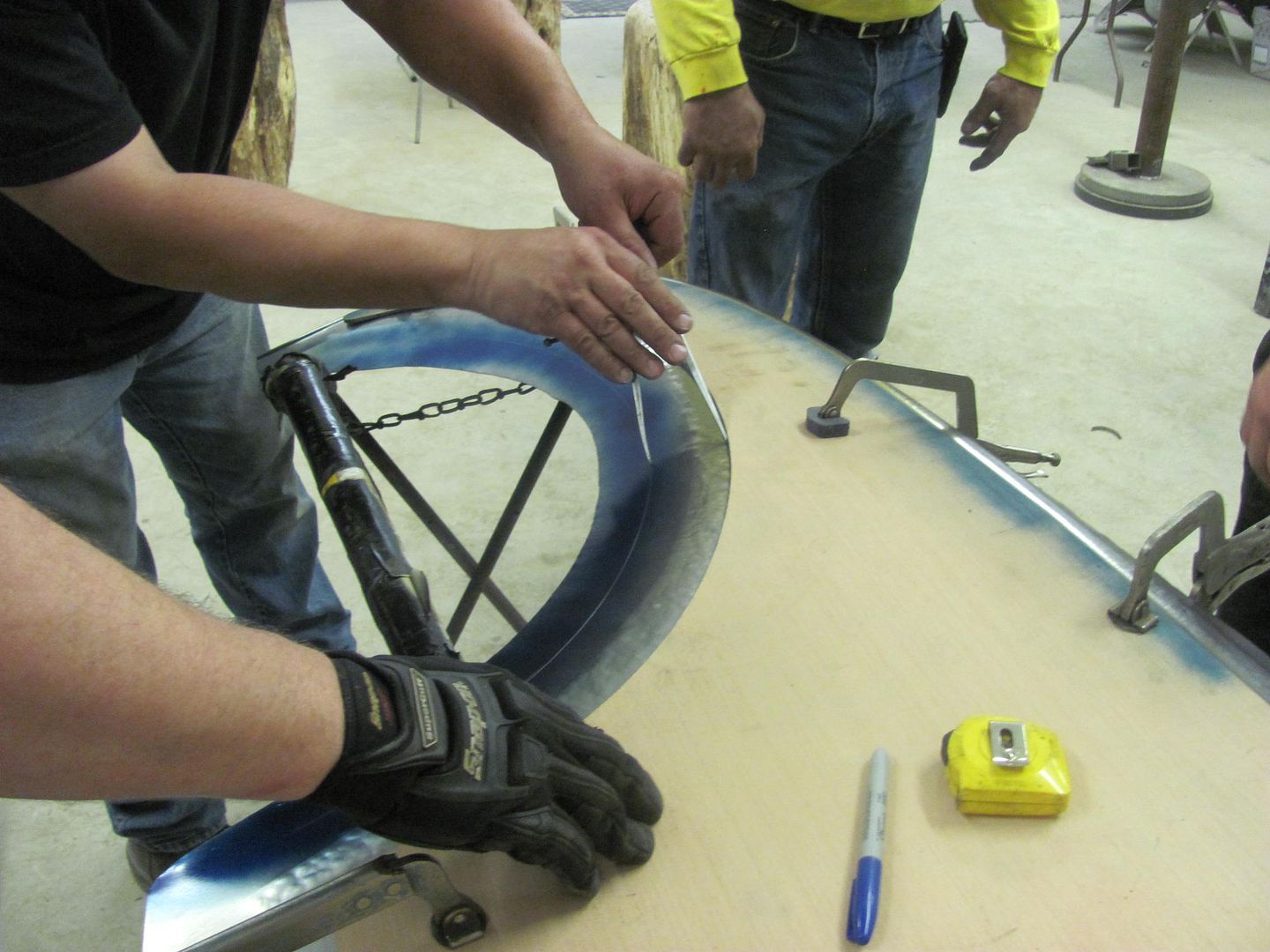

Wiring top edge of the copper trash can..        Roadster quarter, making dies for the upper bead detail....     Sharpening the crease   A bit of shrinking....  Test fit...   Marking for trimming the wheel opening...

|

|

|

|

|

|

#34 |

|

Junior Member

Join Date: May 2010

Posts: 17

|

Inside radius backstop

Scooter fender...  Trimming...  [IMG]http://i5.photobucket.com/albums/y167 /rmccartney/Metalworking/Picture%203399.jpg[/IMG]  Prepping for Sport Coupe door skin removal    We took a short break for a Maryland treat...   of course, using only the correct utensils....   Blocking the top section of the roadster quarter.....

|

|

|

|

|

|

#35 |

|

Member

Join Date: Oct 2013

Location: Holden, Ma

Posts: 41

|

Where is this? I'd love to attend classes

|

|

|

|

|

|

#36 |

|

Senior Member

Join Date: Sep 2015

Location: western n.c.

Posts: 407

|

a few years age ron covel was giving metel working classes in charlotte n.c. I managed to make two of them before the economy crapped out and he stopped the ones in n.c. they were great and I wish I could take some more. I hope to hear more about future classes.

|

|

|

|

|

|

#37 |

|

Junior Member

Join Date: May 2010

Posts: 17

|

Will's class was held in Rock Hill, SC. My class was held in Leonardtown, MD. Here's a tuck shrinking video I forgot to include yesterday.. https://youtu.be/qBG4XNzDKs8 . |

|

|

|

|

|

#38 |

|

Junior Member

Join Date: May 2010

Posts: 17

|

Final update of the class, pictures from yesterday.

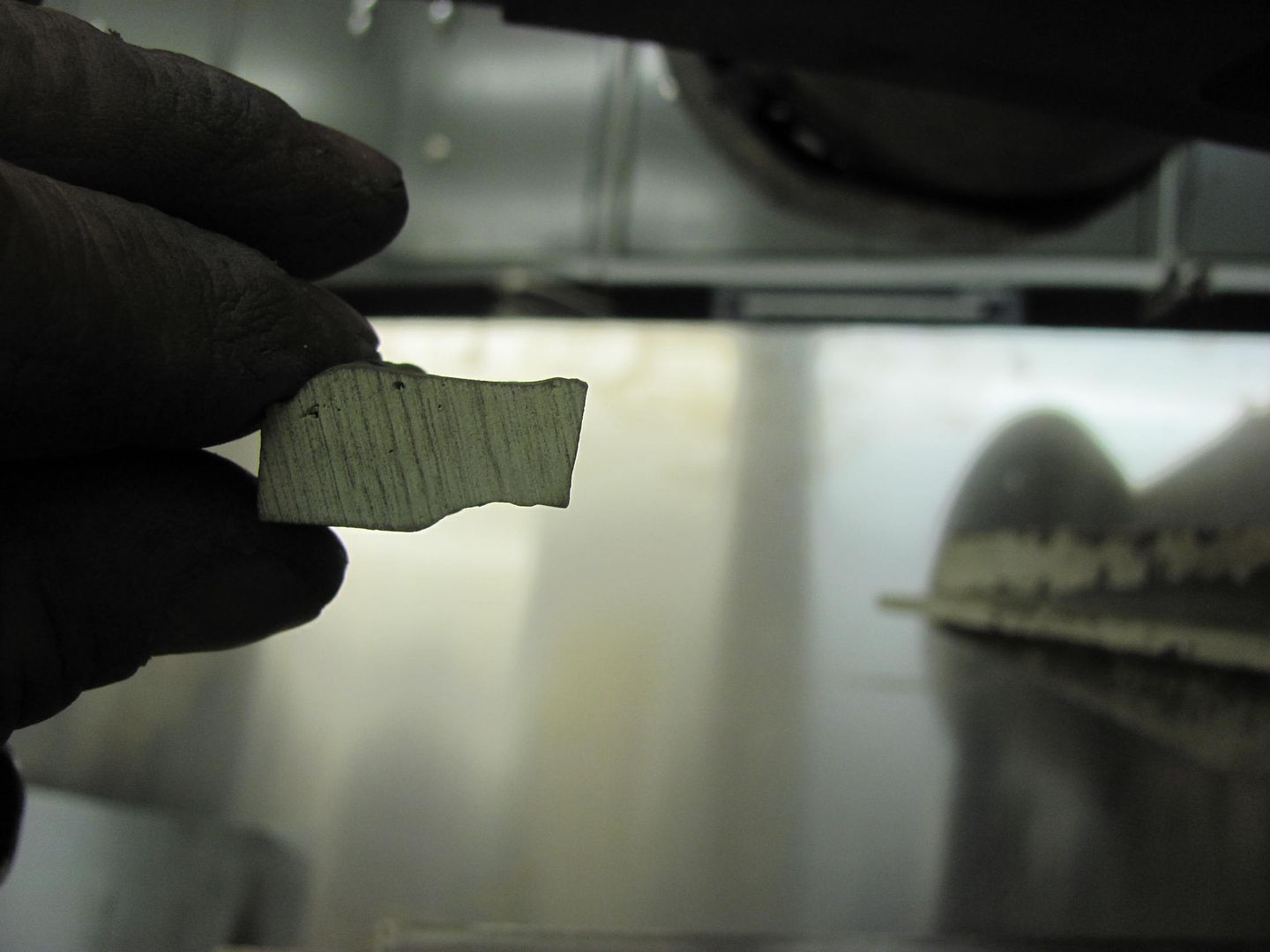

Wheeling door skin for a sport coupe:    Annealing copper wire to use as rivets:     Cover plate for military vehicle:  Paper pattern    Tuck shrinking on post dolly   Forming upper quarter reverse

|

|

|

|

|

|

#39 |

|

Junior Member

Join Date: May 2010

Posts: 17

|

Wheel opening bead detail added

Tipping flange with vise grips with jaws that have been smoothed...  Stretching          Loading stumps for the journey to their new home..    This class has been a blast, Peter is a wealth of knowledge and experience, and we are honored to have him share and pass this on to others. Anxiously looking forward to next year! |

|

|

|

|

|

#40 |

|

Junior Member

Join Date: May 2010

Posts: 17

|

I have some ear protection that was left behind from this weekend, if one of the class participants would like to claim them.....

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 06:57 PM.

Linear Mode

Linear Mode