|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Senior Member

Join Date: Jan 2011

Location: Massachusetts

Posts: 465

|

Has anyone drilled the rear axle to install a vent after installing the torque tube adapter? Is it necessary?

|

|

|

|

|

|

#2 |

|

Senior Member

Join Date: May 2010

Location: Williamsburg, Virginia

Posts: 2,656

|

Yes - did it on the passenger top-side about 10 inches from center of the pumpkin. Tapped and placed a fitting in there for a 1/4" brake line - put a twirl in the line to keep the water/debris out ....

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#3 |

|

Senior Member

Join Date: May 2010

Location: upstate SC

Posts: 2,983

|

I have seen some where a drilled stud was used to replace a bolt on the banjo then a hose was run from there. Drilled carb studs were used for vacuum so you may be able to find one.

|

|

|

|

|

|

#4 |

|

Senior Member

Join Date: May 2010

Location: Napier, New Zealand

Posts: 2,001

|

|

|

|

|

|

|

#5 |

|

Senior Member

Join Date: May 2010

Location: SLC Utah

Posts: 799

|

Drilled mine at about 10 o'clock on the driver's side, to keep it away from the churning ring and pinion.

__________________

RIP Tyler... My Son, Helper & Best Friend. Feb '78 to Father's Day '10. www.97-express.com ~ [email protected] |

|

|

|

|

|

#6 |

|

Senior Member

Join Date: May 2010

Location: Capital of Corruption , NY

Posts: 816

|

Sponsored Links (Register now to hide all advertisements)

http://www.jegs.com/i/Currie/272/95065/10002/-1 |

|

|

|

|

|

#7 |

|

Senior Member

Join Date: May 2010

Location: Mill Valley,Ca.

Posts: 1,509

|

I found that without a vent, there was a pressure buildup from the heat, pull the fill plug after running sometime... This made me think about my rear brakes.

I drilled the torque tube... and added a hose connection. After trying different positions around the banjo, ALL of them produced oil on ground. As a refinement, I put an inline fuel filter on the breather, to filter the air... Karl |

|

|

|

|

|

#8 |

|

Senior Member

Join Date: May 2010

Location: warwick Rhode Island

Posts: 464

|

BUT as CC33 said "is it necessary"?

|

|

|

|

|

|

#9 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

If you don't vent a modified rear axle it will build up pressure and can shove axle fluid out the bearings and seals. Everything I have seen tried on the center section has had problems because of the ring gear throwing so much oil around. I drilled my axle housing about a 1/3 of the distance from the backing plate. In a totally stock Ford banjo rear end this shouldn't be a problem because the axle, torque tube and transmission are all vented together. Modification can mess up this system and require an axle vent. I am running a open QC rear axle and it has to have a vent.

|

|

|

|

|

|

#10 |

|

Senior Member

Join Date: Aug 2012

Location: Perth, Western Australia

Posts: 2,687

|

Thinking about it where does the standard setup vent from?

__________________

"Came too close to dying to stop living now!" |

|

|

|

|

|

#11 |

|

Senior Member

Join Date: Jan 2011

Location: Massachusetts

Posts: 465

|

|

|

|

|

|

|

#12 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

I'm not an expert on original stuff, but it has something to do with the transmission. As long as it is in the system it works. I would guess ether there is venting built into the transmission or it acts as a buffer for the system. I have read all of this in the past just don't remember all the details. It doesn't matter that much to me, if it's stock, it works. If it's modified it needs fixed. Seems simple to me. If people are really that interested in how the stock system works I'm sure I can find the information fairly easily.

|

|

|

|

|

|

#13 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

That's one persons option (not saying it wrong, just saying it's an option). It's not how I would do it, but I'm sure it would work. The issue is staying away from the ring gear, not an exact location. A lot of it depends on your setup and the looks, etc. Mine is on the passenger side out nearer the center of the housing on the backing plate side. There are lots of axles with vents on them if you are looking for some ideas.

|

|

|

|

|

|

#14 |

|

Senior Member

Join Date: May 2010

Location: Qld, Australia

Posts: 4,232

|

My 33 is stock, and on opening the drain plug I got showered in oil,it was pressurised in there,

How would the pressure get past the oil seal on the driveshaft roller,I know that this seal was to keep the gearbox and U/J oil from getting into the rear end but it would take a few PSI to overcome it from the rear side , still I never had any oil in the brakes or loss of oil from the rear,and this was the first time I had drained the rear end oil when it waS hot. But I agree standard it works,I found this out the hard way this last month or so,engine wise and gearbox wise. Lawrie |

|

|

|

|

|

#15 |

|

Senior Member

Join Date: May 2010

Location: pittsfield, MA

Posts: 2,086

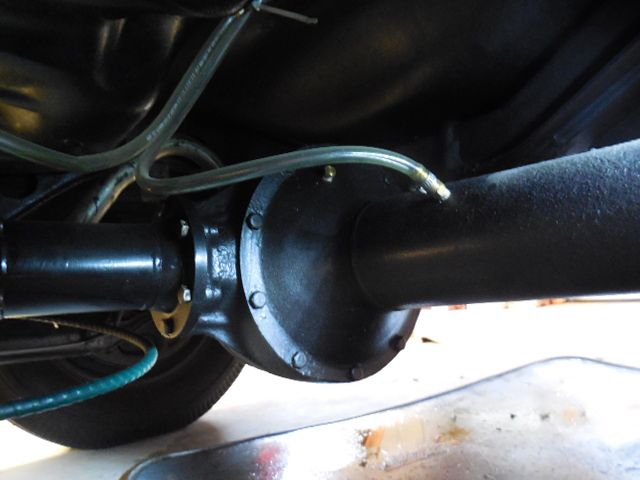

|

When I installed the Mitchell in our 46 the Mitchell had a vent in it. Then I started getting leakage around the banjo from the pressure build up in the differential. Apparently in a stock setup the torque tube and transmission buffer the pressure buildup. So here is how I vented the rearend and no more leakage.

John

|

|

|

|

|

|

#16 |

|

Senior Member

|

The stock set up should not need venting ,on a modified unit a shower restrictor valve from the plumber will do it .Ted

|

|

|

|

|

|

#17 |

|

Senior Member

Join Date: May 2010

Posts: 4,548

|

On my roadster with QC and steel bells I first put a vent in the left bell about 1.5 inch's out from the edge of the center section and had lots of blow by out the vent. Moved the vent about 1/2 way out on the tube toward the axle end and things stayed clean.

|

|

|

|

|

|

#18 |

|

Senior Member

Join Date: Feb 2012

Location: Las Vegas, NV

Posts: 1,260

|

The 8" in my '36 came with a vent tube but without the hose attached, where should the hose vent to and should it have a breather on the end of it?

|

|

|

|

|

|

#19 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

Only if you don't want water/dust in the axle.

Edit: Well, that was a rather poor answer! First off, I miss-read it, thought you said "do I need a vent hose and filter". Sometimes I wonder about my reading skills. I am doing to have to stop attempting to do several things at once, that's for sure. Where the vent hose goes is not important, it is normally routed up near the top of the frame and flooring and looped back down a little. The idea is to limit water getting into the axle. It needs to have enough slack in it so it can move with the axle. Filters are not necessary as there is not that much actual movement of air through the vent hose, mostly a pressure relief. However, some people like the extra margin of security a small filter provides. Last edited by JSeery; 08-14-2014 at 08:37 AM. |

|

|

|

|

|

#20 |

|

Senior Member

Join Date: Oct 2012

Location: Eastcoast

Posts: 864

|

On my 38 I found a rubber plug in the torque tube about 8" from the banjo @ 2 oclock and a metal band that can slide over the hole. I thought this was the vent.

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 10:27 AM.

Linear Mode

Linear Mode