|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Senior Member

Join Date: May 2010

Location: Mpls, MN

Posts: 27,582

|

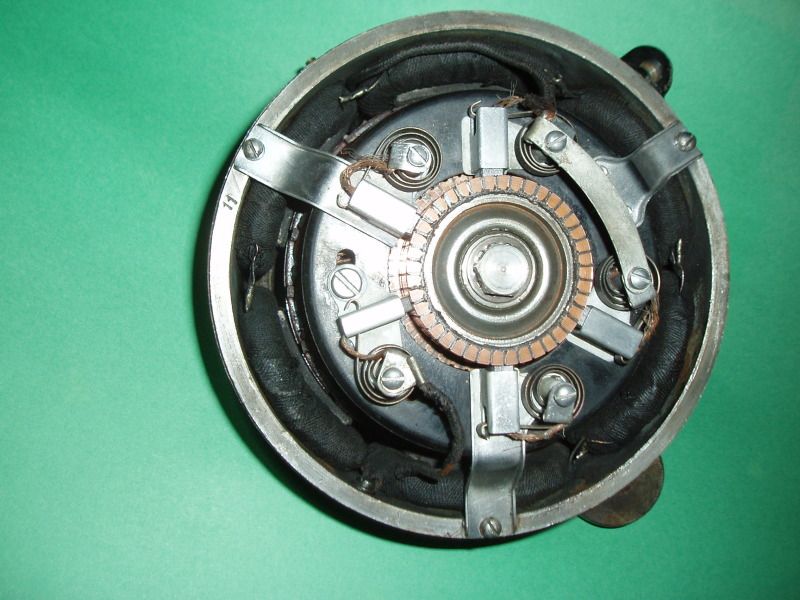

Here's the way I like to see a powerhouse generator. This one has never been touched and the screw heads and bakelite brush holder are in mint condition. When I spun the armature I knew that the grease had to be old and had gotten too thick. This is the original grease, which I've seen before, but this one had the most grease of any generator I've taken apart. I was able to remove the grease and clean the bearings with a stiff brush, gas and compressed air. The bearings were in great shape, so I repacked them with Mystik JT-6 High Temp grease. Another indicator that this generator was never messed with is the bearing retainer nut has no marks on it. This is the first nut that I've seen without chisel marks or plier marks on it. The first picture shows the tool I made to remove and install the nut without leaving marks on the special serrated bearing retainer nut. Someone had given the generator a quicky black spray paint and covered the nut and shield, so I used the wire wheel to remove the paint and then gave them a coat of clear laquer. This must have been left outside, or installed in a car with a leaky water pump because the case has light pitting on the outside of the case. The pits can be filled in with some glazing putty, then painted black. On a good original case you should be able to see the lathe marks from the factory turning the casting. The insides were pretty clean, but I used some gas and my syphon sprayer to clean it up better. The brushes still have a lot of use left, except for the adjustable brush. That brush was worn to the limit, but it will be removed anyway when I install the EVR for the customer. I gave the commutator segments a light undercut, then polished them with fine crocus cloth. As I've mentioned before, the commutator almost never needs to be turned down on a lathe. Sure wish all the generators were this nice. A while back someone asked about the armature to field pole clearance. This one has excellent clearance, so I used my Starrett feeler strips that I use for checking piston clearance. They are 12" long by 1/2" wide. The .005" strip gives a heavy drag on this powerhouse. A close clearance is essential for good output, and that's why the armature should never be ground, turned or sanded to remove rust. A wire wheel will clean them up if they have a light coating of rust.

|

|

|

|

|

|

#2 |

|

Senior Member

Join Date: May 2010

Posts: 1,987

|

Aren't those innards nice, don't you just love the special look of really nice original parts, too bad the outside is lightly pitted...

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#3 | |

|

Senior Member

Join Date: May 2010

Location: Mpls, MN

Posts: 27,582

|

Quote:

I restored a powerhouse about 5 years ago that had really deep pits. After sandblasting the empty case, I filled the pits with JB Weld, then spun it on my lathe while I ran some course sandpaper across the outside of the case to give it the look of lathe cutting. It took a while but came out good. The owner wants to do his own painting on this powerhouse, and since the pitting is fairly light I'd think glazing putty would fill them nicely. |

|

|

|

|

|

|

#4 |

|

Senior Member

Join Date: Jan 2012

Location: Phoenix, Oregon

Posts: 661

|

It appears when the armature was undercut they "chamfered" each bar. This is many times a forgotten procedure. Nice stuff. A chamfering tool is easily made out of a carbide insert. A definite key to long brush life.

Nice look inside. |

|

|

|

|

|

#5 |

|

Senior Member

Join Date: Jun 2010

Location: Redwood City, CA

Posts: 1,591

|

Looks nice and clean inside, you are one of the last true craftsmen around Thomas!

__________________

1928 "A" Phaeton (mid year with many early features) 1933 "V8" Closed-Cab Pickup Truck (originally a Model B, 4 Cylinder dating to May, 1933)

|

|

|

|

|

|

#6 |

|

Senior Member

Join Date: May 2010

Location: Mpls, MN

Posts: 27,582

|

Sponsored Links (Register now to hide all advertisements)

Thanks Al. Here is another picture of it to show the mounting bracket with a good defect. Notice how the recessed part of the bracket is correct at the mounting bolt area, but raised to the point of almost being level at the middle and upper part. I've never seen this happen before, but it does add strength. Some brackets have "FORD" script, as this one does, but this script is upside down from the others I've seen. Toward the end of powerhouse production the brackets were made solid (no recess) for added strength. Also shown are two adjustable brushes. The lower one is a good used one, and the upper one is the worn one that was inside this generator. I never throw out worn powerhouse brushes, because if the day comes when you can't find new ones, I can file a carbon brush to size and use the wire and terminal in the new carbon. Also notice how the screws are staked at the slots. This is noted on the blueprints to be done, but sometimes the 12 screws for the field poles aren't staked. I've never heard of one coming loose though. |

|

|

|

|

|

#7 |

|

Senior Member

Join Date: May 2010

Location: Hancock, New Hampshire

Posts: 375

|

Tom:

This thread reminds me of the Powerhouse you rebuilt for me after finding it at Bert's a few years back. It is, by far, the nicest generator in the stable. Once the cutout kicks in at just above idle, I can idle back down and still see the charge, if called for by the EVR. And I keep the belt adjusted a little loose, the way you suggested. The old Leatherback's charging system is great, thanks to you. Merry Christmas, Hunt |

|

|

|

|

|

#8 |

|

Senior Member

Join Date: May 2010

Location: Portland, ON, Canada

Posts: 315

|

Tom,

My Canadian slant case powerhouse was shipped to you this morning. Looking at these pics tells me Santa is coming early this year.

__________________

Dave A Jamieson Portland, ON Canada 1928 Tudor |

|

|

|

|

|

#9 |

|

Senior Member

Join Date: May 2010

Location: VA

Posts: 1,410

|

Are those bracket screws punch-locked to retain them? Is that done in other places on a Model A?

|

|

|

|

|

|

#10 | |

|

Senior Member

Join Date: May 2010

Location: Mpls, MN

Posts: 27,582

|

Quote:

BTW, when I measured the armature to field poles clearance and found this generator has .005", just for reference, the cover on Bratton's catalog is .010" and an inside page is .004".

|

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 01:41 PM.

Linear Mode

Linear Mode