|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Senior Member

Join Date: May 2010

Location: Proctorville

Posts: 1,582

|

Should have asked first, here is what I have found after several days of on and off work. I placed my restored horns on car, (Don and I placed new chrome horns, horn caps and fixed diaphragms) looked great. We had bench tested them and they sound good, now I installed the new wire from horns into engine compartment and plugged into the wiring harness. Next I connected the yellow wire to hot terminal and the horns BLOW, without pushing the button. Removed the horn caps and looked at everything, tested and found that everything in horn reads to ground. Removed horns today and traveled to Don P.'s garage and we tested, took things apart, replaced parts several times and then decided that I would have to use a starter solenoid that has the battery terminals and uses ground to make and break(like a 41). THEN I looked in Macs and found a note that if you purchase new horns from them to USE A HORN RELAY. Now I know my horns must have been replaced years and years ago. How were the original horns constructed? Were they insulated from chassis ground with bushings or what, learning everyday, thanks for your time, Bruce

|

|

|

|

|

|

#2 |

|

Senior Member

Join Date: May 2010

Location: Altamont, NY

Posts: 1,004

|

The horns blow due to a grounded circuit, its not in the horns it how you have them wired up. The interrupter switch is the horn button, when you push the button the horn grounds and completes the circuit. If you are not pushing the button down somewhere in the circuit, the cap or connection is making a ground and completing the circuit. No solenoid is necessary if you are using the stock wiring.

__________________

dickspadaro.com |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#3 |

|

Senior Member

Join Date: May 2010

Location: Ashland KY

Posts: 1,159

|

If the horns are mounted to the horn mounts,,, THIS IS GROUND and the horns blow unless the horns are insulated from ground someway at the mounts

__________________

DON P |

|

|

|

|

|

#4 |

|

Senior Member

Join Date: May 2010

Location: Altamont, NY

Posts: 1,004

|

No Don, these horns are not internal ground horns there are two wires hooked to the horn much like a regular lamp cord. One wire is the power the other is the ground, the circuit is completed when you push down on the horn rod. The power flows thru the horn when the button grounds and thus the horn beeps. Bruce from OH's issue is that his horn blows immediately when power is applied indicating that somewhere the circuit is grounded.

__________________

dickspadaro.com |

|

|

|

|

|

#5 |

|

Senior Member

Join Date: Jun 2010

Location: San Antonio, Texas

Posts: 16,436

|

With a relay in the circuit, the horn body has to be grounded in order to complete the ground path of the horn coil to the horn body internally. This only requires the one wire for power from the relay to the horns. If there is no relay then there would have to be a switch in either the power side of the circuit or the ground path side of the circuit. If it is ground path the there would have to be two wires going to each horn and the horn bodies would be insulated from both the power and ground paths of the horn coils. If the switch is in the power circuit side of the horn coils then only one wire would be necessary since the horn bodies could provide the ground path. I would have to look at the electrical diagram to tell which way it was supposed to be. I know my model A has a 2 wire system

|

|

|

|

|

|

#6 |

|

Senior Member

Join Date: May 2010

Location: Ashland KY

Posts: 1,159

|

Sponsored Links (Register now to hide all advertisements)

__________________

DON P |

|

|

|

|

|

#7 |

|

Senior Member

Join Date: May 2010

Location: Altamont, NY

Posts: 1,004

|

Don, There is none. Now think of your horn like a light bulb, the horn has power coming in on one wire, goes thru the horn vibrator and exits the other side wire. The other side wire is power out and is routed to the headlight switch body indexed with the center contact. Just like this hooked up no beeps becuse the circuit is not closed, but when you press down on the horn button the horn rod shaft depresses in the steering column and the tip of the shaft makes contact with the button in the center of the light circuit and the head of the buttom makes contact with the brass contact in the horn rod that grounds the circuit to the steering shaft and walla the horn beeps. In a house lamp it works the same way one wire in power, one wire out ground, when you flip the wall switch the lamp lights because you completed the circuit . Same principle here. Because your horn beeps as soon as you apply power means there is a closed circuit somewhere after then headlight switch body or in the headlight switch itself because there is an immedaite uncontroled ground.

__________________

dickspadaro.com |

|

|

|

|

|

#8 |

|

Senior Member

Join Date: May 2010

Location: Proctorville

Posts: 1,582

|

Dick, just got home, reading your response, the horn in free air (not attached to the chassis ) is isolated. Now when I bolt/connect the horn to the chassis the horn is now attached to the car which is the ground (return path ), just like the head lights work. The horns are always fed hot and when you push the horn button the ground should make horn blow. What I asked is or was there different horn construction with the horns isolated from chassis. The thing that made me/Don come to the conclusion that some later horns were made different is that MAC's says a relay is needed, not just for handling the load (amperage) but because the new horns are not the isolated frame type, thanks for your thoughts and time, will advise as what I find. Several have PM'ed me and this seems to be the case (non-isolated frame), cheaper to construct like later model horns which use the chassis and one wire.

|

|

|

|

|

|

#9 |

|

Senior Member

Join Date: May 2010

Location: Proctorville

Posts: 1,582

|

Horn Construction:

A typical car horn consists of a flexible metal diaphram (usually made of spring steel), a coil of wire that forms an electromagnet, a switch and a housing that functions somewhat like a megaphone. The entire apparatus functions according to Hooke's Law, which states, "The extension of a spring is directly proportional to the load applied, provided the limit of proportionality is not exceeded." This is fancy wording that means, simply, that if you design the horn properly the flexible diaphram will oscillate back and forth continuously as long as current is applied. This will translate into the sound desired. Horns are constructed with a flexible electrical contact that is attached to - or actuated by - the flexible diaphram. A strong electromagnet that moves a central armature is connected to the flexible metal diaphragm. When current is applied to the electromagnet the armature moves to its mechanical limit, momentarily disconnecting power. As it relaxes back to its starting point, electrical contact is again made and the armature starts its travel again. As you might imagine, moving all this mass to create a loud, sustained sound that is often in excess of 90 decibels in loudness takes a lot of energy. That energy is electrical current, of course, and in cars equipped with electromechanical horns the only accessory that uses more is the starter. Headlights, power seats, etc., individually don't use as much current as the horns. That's why the wiring and terminals associated with horns are so large, and also why a relay is necessary to actuate the horns. In actual operation, one presses the horn button and at that moment the electrical contact allows current flow to the relay, which in turn furnishes high current to the horn's electromagnet. That, in turn, attracts the diaphragm, which flexes to its mechanical limit. This disengages the contact, which stops current flow to the electromagnet. The diaphram is released to travel back past neutral position closing the switch again, and thereby pulling the diaphragm back, setting up an even oscillation. |

|

|

|

|

|

#10 |

|

Senior Member

Join Date: May 2010

Location: Ashland KY

Posts: 1,159

|

I wish you had told me all this today........?????

__________________

DON P |

|

|

|

|

|

#11 |

|

Senior Member

Join Date: May 2010

Location: Melbourne Australia.

Posts: 2,079

|

Dick Spadaro, 10 out of 10 for your horn explanation for ORIGINAL FORD V8s. Original SPARTON 33-34 ford horns require two wires connected to them. One is power (neg) and the other goes to ground (positive) via the horn button. The horns internal circuit is insulated from ground and its mountings, ie NO CONNECTION whatsoever. Sounds like the repro horns are different in that they are internally grounded on their mountings and require a switched (horn button) power wire. Only one wire coming out of that horn and that's why a relay is required so that the grounding horn button grounds the relay coil and the relay contacts then pass negative power feed to that single horn wire. Same old story with many repro parts, they don't make em right, PITY. Regards, Kevin.

|

|

|

|

|

|

#12 |

|

Senior Member

Join Date: May 2010

Location: Proctorville

Posts: 1,582

|

Thanks Kevin, the give away for me should have been the one terminal screw only. I purchased car in February, have taken everything apart at least once, I was trimming out the car if you want to call it that and the horns were one of the last things I was installing. Don cleaned up horns, painted, tuned them, and placed new chrome tops and trim on them, look GREAT! But this car has sat sense 1982 and I have no history of repairs, the horns did on even work due to bad wiring and broken diaphragms inside the existing horns. We have now figured out how to make them work, but as you say, many repro parts, they don't make em right, thanks everyone and if more information is found forward to me or post, Bruce

Found this site, could be of interest: http://www.delcoremyhistory.com/Serv...orn%201933.htm |

|

|

|

|

|

#13 |

|

Senior Member

Join Date: May 2010

Location: Altamont, NY

Posts: 1,004

|

Sorry for the confusion but your first post said you restored your horns, to me that means you were using original horns, thus the post response. If you have the single post reproduction horns well yes they are internally grounded. When you figure out how to adjust them or get them to work on a regular basis please post a how to on the web site. I'm tired of fooling with them, seems like the warranty is 5' or 5 beeps which ever come first.

__________________

dickspadaro.com |

|

|

|

|

|

#14 |

|

Senior Member

Join Date: Jun 2010

Location: San Antonio, Texas

Posts: 16,436

|

I've seen diaphragms on repro horns that crack out after only a few heavy honks. The OEM part is well worth restoring if you can find a decent core. If it is a one wire repro horn, a person can find the ground path connection inside the horn works and isolate it then find a way to attach a terminal to it for a ground path back to the switch wire.

|

|

|

|

|

|

#15 |

|

Senior Member

Join Date: May 2010

Posts: 1,835

|

Good explanation from Dick Spadaro on two wire Ford horns. I think Ford used the two wire,body of horn isolated up to and including the 1937 Fords and in 1938 started using the body ground one wire that requires relay in 1938. Found this out from a pair of 1938 Ford standard horns,they look exactly like a pair of 1937 Deluxe horns except they have a single wire only compared to the 37 horns with two wires each the one being the ground wire.

__________________

"Never complain,never explain"... Henry Ford II |

|

|

|

|

|

#16 |

|

Senior Member

Join Date: May 2010

Location: Proctorville

Posts: 1,582

|

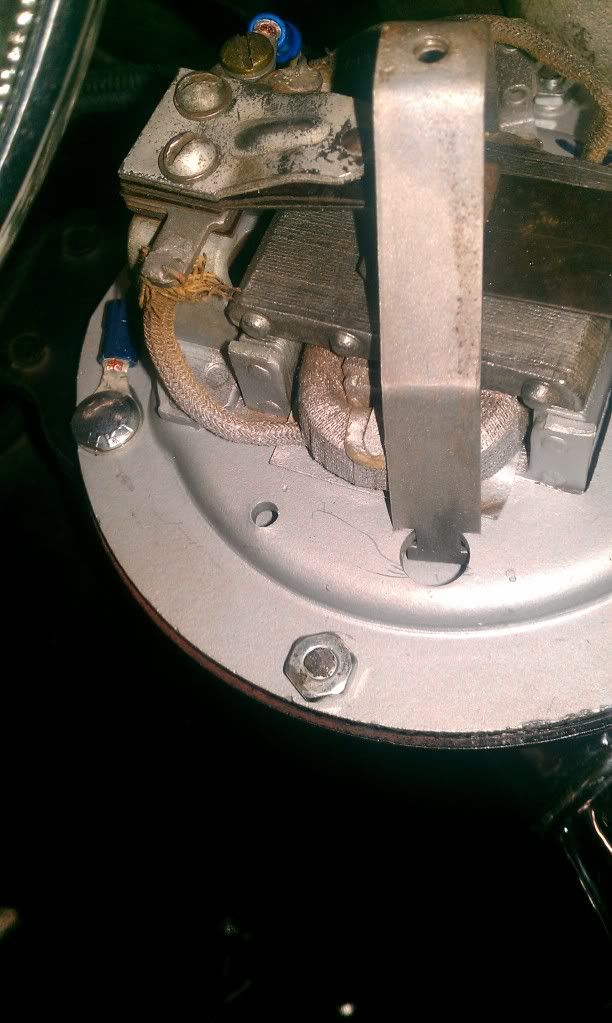

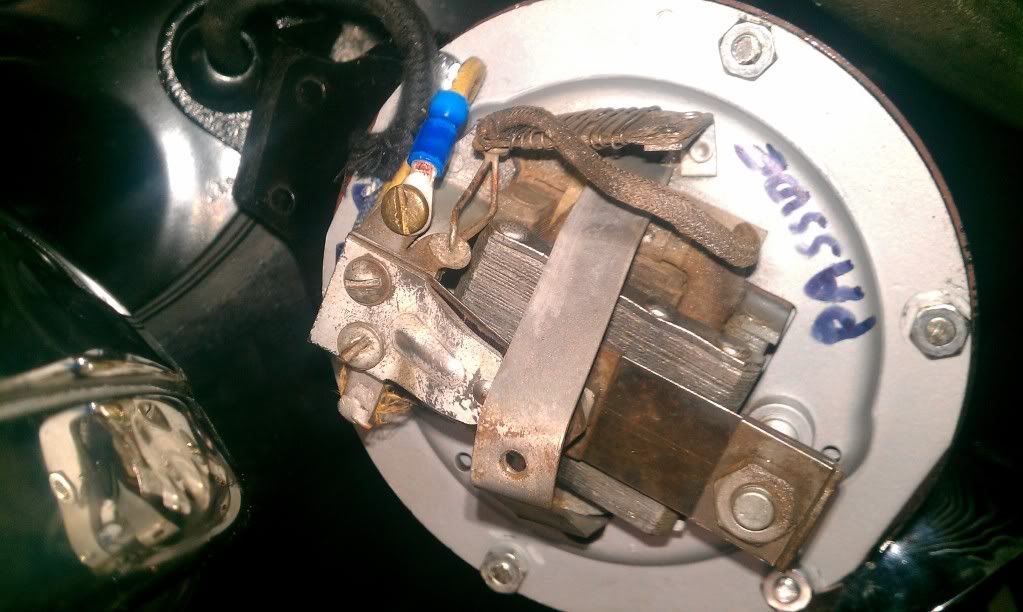

Dick/37 Coupe, I now believe that they are 1938 and up as 37 Coupe says if that is when Ford started using one wire horns. The reason is that it has an open type wire wound resistor on a silicon type board. (about 1/2" wide X 1" long ). I called it restoring because I did fix the horns from not working to working, replaced all the parts, painted and tested, I did not know at the time they were not original internal parts.

.  . I you notice the resistor is to ground, but if you remove the resistor out of circuit it goes supper hot quick! .  . Dick/37Coupe/Don, everyone, also must be old type, have now blown the horn about a couple hundred times, still working. Thanks for comments and help, makes the ride in old Ford a lot more fun. Very loud, might just use one at a time. |

|

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 07:27 PM.

Linear Mode

Linear Mode