|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Senior Member

Join Date: May 2010

Location: midlothian illinois

Posts: 447

|

My rebuilder and I are looking for either a blueprint for an 8ba torque plate, or the possibility of renting one from someone so we can finish the bore and honing of the block so we can move onto other more pressing things. Just a side question; would it be possible to use this plate for pressure testing the block? Thanks, Steve

|

|

|

|

|

|

#2 |

|

Senior Member

Join Date: May 2010

Location: Oshkosh, Wi

Posts: 4,527

|

Take a cylinder head and bore out the holes over the pistons. It then can be used to pressure test also --- NOT

Last edited by flatjack9; 04-06-2018 at 09:25 PM. |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#3 |

|

Senior Member

Join Date: May 2010

Location: Masterton, New Zealand

Posts: 3,841

|

Sorry Jack, if one bores a head out over the cylinders, you'll be into water passages so can't use for pressure test. Would make torque plate ok.

__________________

Unfortunately, two half wits don't make a whole wit! |

|

|

|

|

|

#4 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

A cylinder head should be a good pattern for a torque plate. And it would work well for pressure testing as well.

|

|

|

|

|

|

#5 |

|

Senior Member

Join Date: May 2010

Posts: 886

|

I took a 2 inch thick piece of aluminum drilled the plate while using the head as a bolt pattern then took an old piston that had a small centering hole in it then drilled out the center and sharp pointed a bolt and screwed it in the center hole and after bolting the already drilled plate to the block I tapped the piston with the bolt centered in the old piston as a pilot hole to use as a starting point, scratched the diameter of the cylinder bore as a reference point then drilled and bored a 3-3/8 hole for the cylinders , bolted it down and used a neoprene gasket as a seal then used it as a pressure tool and a torque plate. I had to have the plate surfaced to get an accurate even torque and seal the pressure head gasket, I later counter bored the hone plate to accept allen head counter sunk bolts.

|

|

|

|

|

|

#6 |

|

Senior Member

Join Date: Dec 2012

Location: Anchorage Alaska

Posts: 291

|

Sponsored Links (Register now to hide all advertisements)

|

|

|

|

|

|

#7 |

|

Senior Member

Join Date: May 2010

Location: midlothian illinois

Posts: 447

|

I appreciate all the suggestions & directions, but I do not have any cylinder heads to either bore one out for a torque plate or even use one for a pattern, so I am out there asking for a blueprint to make one. Just a side bar question, if I find a single cylinder head (left or right) would that one head work for both sides as a boring / torque plate or do I need left & right examples? I guess I could search Craigs list around here for one.

|

|

|

|

|

|

#8 |

|

Senior Member

Join Date: May 2010

Location: Oshkosh, Wi

Posts: 4,527

|

I'll give you one if you want to pay shipping. In fact I can give you 2. By chance do you go to the swap meet in Jefferson, Wi. at the end of April?

|

|

|

|

|

|

#9 |

|

Senior Member

Join Date: May 2010

Location: Eagle River,Alaska

Posts: 354

|

Why can't you use a head gasket to make a pattern from"

|

|

|

|

|

|

#10 |

|

Senior Member

Join Date: May 2010

Location: Masterton, New Zealand

Posts: 3,841

|

I made my own in both 21 and 24 stud configuration , able to accommodate up to 3 7/16" bore. Pity I'm in New Zealand...

Can't upload pictures, dunno why?

__________________

Unfortunately, two half wits don't make a whole wit! |

|

|

|

|

|

#11 |

|

Senior Member

Join Date: Apr 2015

Location: Sweden

Posts: 3,045

|

|

|

|

|

|

|

#12 |

|

Senior Member

Join Date: May 2010

Location: Masterton, New Zealand

Posts: 3,841

|

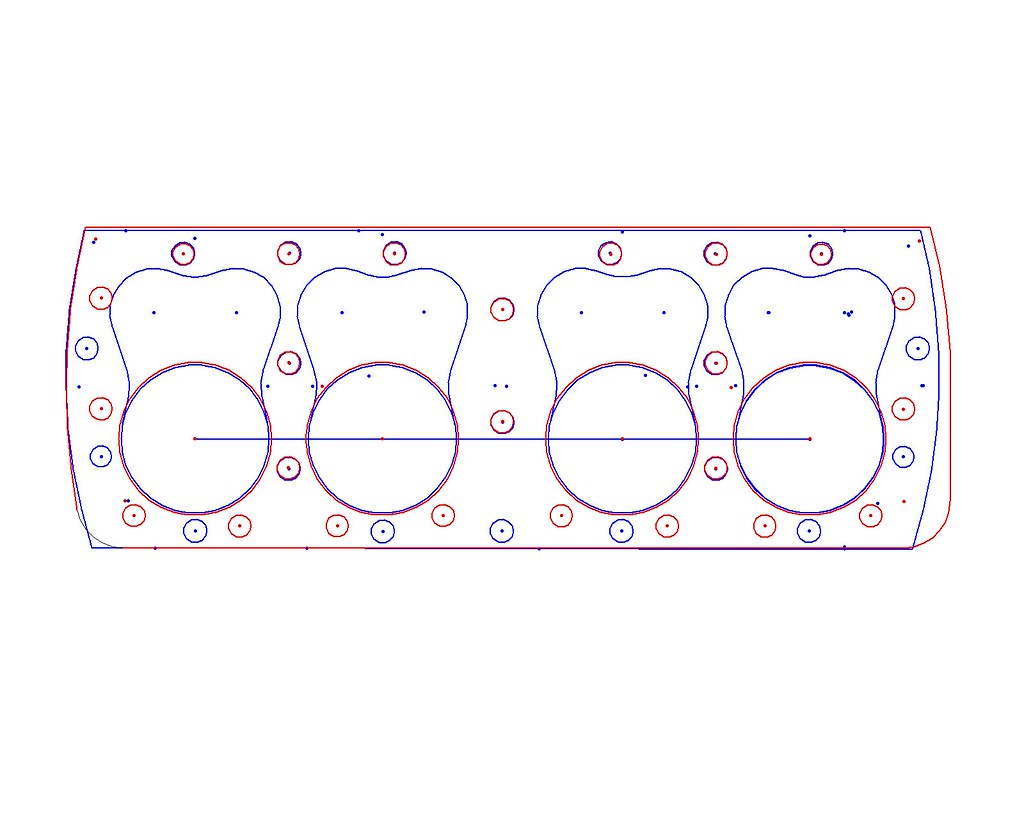

Thanks Murre, we'll try this;

__________________

Unfortunately, two half wits don't make a whole wit! |

|

|

|

|

|

#13 |

|

Senior Member

Join Date: May 2010

Location: Eagle River,Alaska

Posts: 354

|

So since we are on this subject, is a aluminum torque plate ok or should it be made out of steel? Would aluminum be strong enough to stress the block correctly? What should the thickness be for either material ?

|

|

|

|

|

|

#14 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

OK, first some heads are aluminum! But the real issue is the thickness of the torque plate. A 3 inch aluminum plate is going to be stiffer than a 1/4 inch steel plate. It is all going to depend on the material you use and the relative stiffness.

|

|

|

|

|

|

#15 |

|

Senior Member

Join Date: Jan 2011

Location: Central Ohio

Posts: 5,095

|

I have complete deck surface CAD models - in 3D SolidWorks formats (for custom cylinder heads).

I'd be happy to make a 'deck surface plate' model for you - if you're going to use a CNC milling machine to do the work (which is how I'd do it). If you're just going to manually make a plate - just using an old head to 'center punch' an aluminum plate would be the easiest. If you're thinking CNC and somebody understands what I'm saying about SolidWorks CAD models (or DXF files) then I'd be happy to work with you. Obviously whatever CNC program you're using - you'd need to be able to import SolidWorks 3D models and/or DXF 2D vector files to build your machining tool paths from. So if this is the approach you're taking, let me know. The only stipulation or catch is that if you go the CNC approach, I'd like to have a deck plate as a result. I'm happy to pay for materials and help the process through - maybe we can make it a "win win" for all involved. Anybody have CNC capabilities and want to get on board . . . just PM me. Best of luck, Dale |

|

|

|

|

|

#16 |

|

Senior Member

Join Date: May 2010

Location: midlothian illinois

Posts: 447

|

Although not my rebuilder, I lnow someone that does CNC water jet cutting , so would this be the same process and also accurate enough for this application? I probably do not know enough to ask the right questions.....

|

|

|

|

|

|

#17 |

|

Senior Member

Join Date: May 2010

Location: near Washington, DC

Posts: 559

|

Just as a point of reference, deck plates for flatheads are available from at least two sources:

BHJ Products: http://www.bhjproducts.com/ CCA Racing Products: https://ccaracing.com/

__________________

Those who do not move do not die, but are they not already dead? |

|

|

|

|

|

#18 |

|

Senior Member

Join Date: Jan 2014

Location: Holmen,Wisconsin

Posts: 788

|

John R,

Thanks for that info, CCA is not far from me, good to know. A related torque plate question, must a torque plate be the EXACT size of the intended bore? I ask because I would consider buying a plate if I could have it the largest I might ever need, even if the current build is slightly smaller.

__________________

I went, I saw, I bought the T shirt 51 Ford Deluxe Tudor 32 Ford roadster 39 Mercury Towncar |

|

|

|

|

|

#19 |

|

Senior Member

Join Date: Apr 2015

Location: Sweden

Posts: 3,045

|

Heads arenīt made to bore size so why would a hone plate...itīs not that sensitive.

Itīs more about the force on the headstud/bolt deforming the bore. |

|

|

|

|

|

#20 | |

|

Senior Member

Join Date: May 2010

Location: Long Island, NY

Posts: 1,052

|

Quote:

Logic would seem to dictate when you Torque the bolts/studs the threads would have a tendency to "push" themselves INTO the bores, but the exact opposite is true. The threads try to pull away from the walls, they "work" the threads opposite of what would seem logical. On many of the "race" blocks we use here the plate actually makes no noticeable distortion at the tops of the bores when Torqued in position. Thanks, Gary in N.Y. P.S. On very high-end builds there are plates that mount on the heads to duplicate the forces when doing any machining (on the heads), specifically in the valve-job area!

__________________

http://www.stromberg-bulletin.com/me...berg-equipped/ |

|

|

|

|

|

|

#21 |

|

Senior Member

Join Date: Nov 2011

Location: Tallahassee, FL

Posts: 175

|

Wow, $765 for a torque plate.

—louis |

|

|

|

|

|

#22 |

|

Senior Member

Join Date: May 2010

Location: Masterton, New Zealand

Posts: 3,841

|

"On very high-end builds there are plates that mount on the heads to duplicate the forces when doing any machining (on the heads), specifically in the valve-job area!"

Which is why I cut out that area on my torque plates as pictured.

__________________

Unfortunately, two half wits don't make a whole wit! Last edited by Brian; 04-09-2018 at 12:00 AM. |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#23 |

|

Senior Member

Join Date: Apr 2015

Location: Sweden

Posts: 3,045

|

And this just reminds me why high-end gives me a sour taste in the mouth...not even mention hot honing a block...stock is soooooo good..lol

The amount of pain that people are willing to go through for thoose last 5hp... Only "high-end" invention to be loved in engine machining is diamond tooling...that ugly smelly brown sunnen hone oil used to keep my hands in a lovely lobster red tone...diamonds and synthetic cutting fluid is a gift from above ! From now im going to charge extra for ancient torqueplates next time anyone brings in a block with studs in it...

|

|

|

|

|

|

#24 |

|

Senior Member

Join Date: May 2010

Posts: 886

|

Flatheadmurre, I was wondering about using the boring bar stud spacers for a torque plates , I have one my late father used to adapt for a portable boring bar, to bore the older 59 blocks , so good that you mention (hot honing ) as my pa used to call it, he would circulate hot antifreeze through the block as he honed to final size, I asked him why ? and he said that's the way I want to do it , I later discovered he picked up the Idea from some Nascar engine builder he knew, Thanks for the memory!

|

|

|

|

|

|

#25 |

|

Senior Member

Join Date: May 2010

Location: Masterton, New Zealand

Posts: 3,841

|

I don't know if it's about chasing that last 5 HP, the instructions that come with Ross pistons recommend the use of torque plates, and give explicit instructions about the honed finish. Why ignore their instructions?

__________________

Unfortunately, two half wits don't make a whole wit! |

|

|

|

|

|

#26 |

|

Senior Member

Join Date: Apr 2015

Location: Sweden

Posts: 3,045

|

Sponsored Links (Register now to hide all advertisements)

|

|

|

|

|

|

#27 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

And 5 hp is a lot on a flathead!

|

|

|

|

|

|

#28 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,876

|

I took an old cast iron head, 3" hole saw and a gasket. cut the head. Then bored it to 3 1/2. works on both sides. Have used it for over 30 years.. Seems to work fine. Also use it for pressure testing.. had it resurfaced after all the machine work.

|

|

|

|

|

|

#29 | |

|

Senior Member

Join Date: Nov 2010

Location: Lancaster PA

Posts: 535

|

Quote:

I could mill cavities in a stock head and use that, might still do that. To use it for pressure testing it would be nice to have the complete combustion chamber open in order to see the ports and valve seat area, which a round hole wouldn't allow. Milling the entire chamber out of a stock iron head might make it pretty flexible, I wouldn't know until it was done. It would certainly be the cheapest way. I sent DXF files to a water jet firm for some quotes. Here's what I got back - 1 Gasket plate, 1/2" 6061 Aluminum 1 /EA $124.57 10 /EA $71.66 2 Gasket plate, 1/2" 1018 Flat bar 1 /EA $305.14 10 /EA $99.53 ^^^^^ I thought 1/2" or less would be handiest for pressure testing. 21_STUD-PLATE-1.53 Gasket plate, 1 1/2" 6061 Aluminum W/Holes 1 /EA $313.17 10 /EA $252.63 ^^^^^1-1/2 Material would be close to the average thickness of a stock head. Would require washer/spacers under the long studs and would require counterboring for the short studs. 21_STUD-PLATE-1.54 Gasket plate, 1 1/2" 6061 Aluminum W/out Holes 1 /EA $252.67 10 /EA $194.88 ^^^^^ This is the thick plate with no holes, to allow drilling the holes instead of waterjetting them 21_STUD-PLATE-RUBBER 5 Gasket plate, 1/8" Neoprene rubber 1 /EA $109.21 10 /EA $34.08 21_STUD-PLATE-RUBBER 6 Gasket plate, 3/16" Neoprene rubber 1 /EA $124.70 10 /EA $39.16 ^^^^^ Rubber gaskets cut to the same shape for pressure testing. For $124 for one I'll cut my own. Waterjet tolerance on the 1/2 plate is about +/- .005, which would give bolt holes up to .020 oversize, which would be OK. On 1.5" plate it would be +/- .015 which is why I asked for a quote w/o the holes. There is discussion by race engine builders about ideal block plates, thickness, material, etc. to duplicate the effect of the head being attached, that's why I asked for aluminum and steel and 2 thicknesses. I priced a piece of Durabar grade 40 cast iron bar, it costs over $300 just for the bar so I stopped there. This makes the BHJ plates look like a bargain. Steel would stand up better to repeated torquing than aluminum. I'm not concerned about stressing the block "straight" with the heads because the flathead heads are so thin, I think they will conform to the block. I just need to pull on the studs/bolts to distort the cylinder bores the same as they will be when the heads are on and torqued. So for that I think an aluminum plate in 1/2 to 3/4 thickness will be plenty. It doesn't look practical to make a combined plate for honing, because the 21 stud pattern interferes with larger bore sizes possible in a 24 stud block. You could make pressure test plates with both, and in that case you could go even thinner, like maybe 1/4". This geometry is reverse engineered from a gasket, so we can't know how close to correct it is to the OEM locations - that would require a Ford drawing. I think it's close enough to use for this. I found that both gaskets had 2 holes smaller than the rest, I imagine those were to locate the gasket on those 2 studs and the rest are larger to make it easier to install over the studs. A nearby friend has his own 24 stud plates in both aluminum and steel, now that he has the aluminum plate he doesn't use the steel one just because the aluminum plate is so much easier to handle. On that subject I think I'd add material on the ends and cut a hand hold in each end to make them easier to install and remove. These prices don't save me much over whacking my own out of plate on a CNC mill in my own shop so I'm probably going to just mill my own then I have control over the whole process. Roughing a thick one out on a waterjet then drilling it on a CNC would cost about the same as milling it complete so that's out I'm willing to share the geometry and the contact info for the local waterjet firm, they are very competitive on other plasma and lazer work I've had them do, but shipping these any distance would add enough to the cost that you might be better off doing it locally. This firm said the programming for a 2D part like this is only about $25 and that's added into these quotes in the part prices. Maybe a group buy is a possibility but I'm not the guy to orchestrate that. Last edited by Yoyodyne; 04-22-2018 at 03:06 PM. |

|

|

|

|

|

|

#30 |

|

Senior Member

Join Date: May 2010

Location: Canada Where it snows

Posts: 2,058

|

Not many are going to step up for this little beauty.

http://honingplates.com/index.php?ma...roducts_id=114 R |

|

|

|

|

|

#31 | |

|

Senior Member

Join Date: Nov 2010

Location: Lancaster PA

Posts: 535

|

Wow, I was remembering $350 - $400

Quote:

|

|

|

|

|

|

|

#32 |

|

Senior Member

Join Date: May 2010

Location: midlothian illinois

Posts: 447

|

At this point in my life, if something else can go terribly wrong, it will! My engine builder & a very good friend too, suddenly dies from hospital complications to a great initial surgery

I just retrieved my block from the family while they were cleaning out some of the shop, and now I am back at step one..... A very sad day for many people I just retrieved my block from the family while they were cleaning out some of the shop, and now I am back at step one..... A very sad day for many people

|

|

|

|

|

|

#33 |

|

Senior Member

Join Date: Nov 2010

Location: Lancaster PA

Posts: 535

|

Oh my!

Condolences all around, I'm really sorry to hear that! |

|

|

|

|

|

#34 | |

|

Senior Member

Join Date: Jan 2011

Location: Central Ohio

Posts: 5,095

|

Quote:

If you need block/engine machine work done, you can always put it on a pallet and send it to Fowler Engines here in Columbus. They do all my machine work for all sorts of engines -- vintage and modern. They are a very experienced and well equipped place and Jeff Fowler and crew are extremely knowledgeable on all sorts of engines. Anyway - if you're looking for options, they might be one. Dale |

|

|

|

|

|

|

#35 |

|

Junior Member

Join Date: Oct 2012

Posts: 9

|

Wow, small world. I am a member here from when my wife inherited her father's Model A and just happened upon this post while reviewing market opportunities (I just bought CCA Racing Products in January). I hope the OP has tracked down someone to get him sorted since this was first posted, but if not, I have no trouble adding a 24-bolt Flathead plate to my rental inventory. I hate to see folks not using plates because they are too expensive to buy.

I've gotta run - it is over 40 degrees outside and it rained all day yesterday to wash the salt off the roads. If this isn't a good day for a cruise I don't know what is.

|

|

|

|

|

|

#36 |

|

Senior Member

Join Date: May 2010

Location: Daytona Beach, Fl & Spencer, W. Va,

Posts: 4,442

|

It is also IMPERATIVE to use the same gasket with the torque plate that you'll be using on the engine. Using the gasket makes a big difference... especially with heads that have a fire ring around the bore. Use the same bolts and torque numbers that will be used on the engine as well. Some go as far as to use it when doing the valve job. But, using the GASKET with it is the most important thing to remember.

__________________

Mike Jr. here. I get on here every few months to check messages, and look through his almost 500 saved messages for information on the '29 and '34 I still have. A lot of very nice people on here. He truly enjoyed Ford Barn. |

|

|

|

|

|

#37 |

|

Senior Member

Join Date: Jun 2010

Location: San Antonio, Texas

Posts: 16,457

|

Flatheads have a weaker cylinder deck due to thickness plus all the valve pockets & that. That's one reason that excessive heat will crack them so easy.

|

|

|

|

|

|

#38 |

|

Junior Member

Join Date: Oct 2012

Posts: 9

|

To expound on what FL&WVMIKE wrote, the way most people use torque plates is actually not really the "right" way, but gets you most of the way there and is certainly better than nothing.

The correct procedure to get "perfect" cylindricity is to torque the head on with the gasket and fasteners you will be using, flip the block upside down, and then map the bore using a dial bore gage (or CMM if possible to speed things up). Then, you install the torque plate and tighten the fasteners until you duplicate the original bore map, not necessarily to the "correct" torque for the fasteners during final assembly. This takes up to a few days to complete and is only used at the top level of motorsports (think Pro Stock - I got this procedure from Darrin Morgan). At the level most of us use them (not full ampping), it is still imperative to remove as many variables as possible, so things like gasket, fasteners, etc. should be the same as what we will use in the final assembly. For instance, I do make plates with o-ring grooves for a "top fuel" style stainless o-ring and copper gasket arrangement to duplicate bore distortion *as best as possible* without performing a full mapping job. This is also why we use the custom DOM spacers for the application; so the end user uses their exact fasteners without having to mess around stacking washers to the heavens. Hope this helps. |

|

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 12:18 PM.

Linear Mode

Linear Mode