|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Senior Member

Join Date: May 2010

Location: Mpls, MN

Posts: 27,582

|

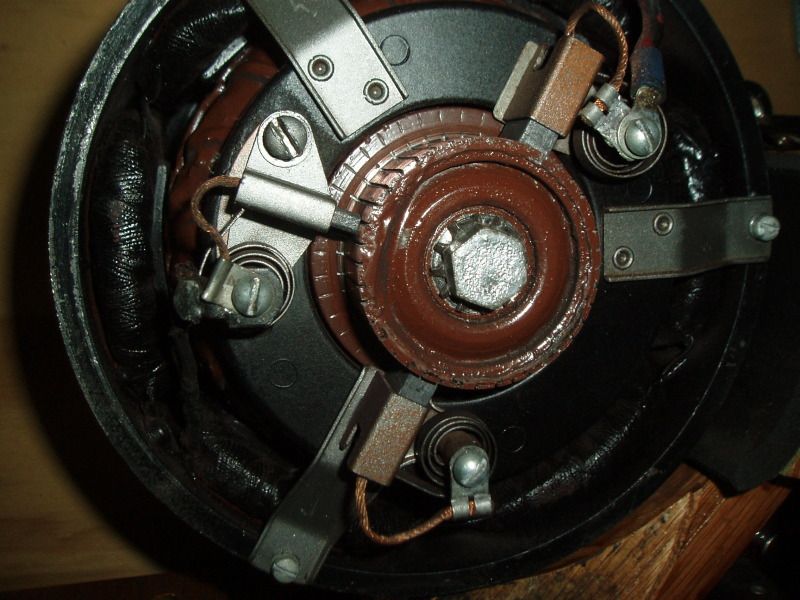

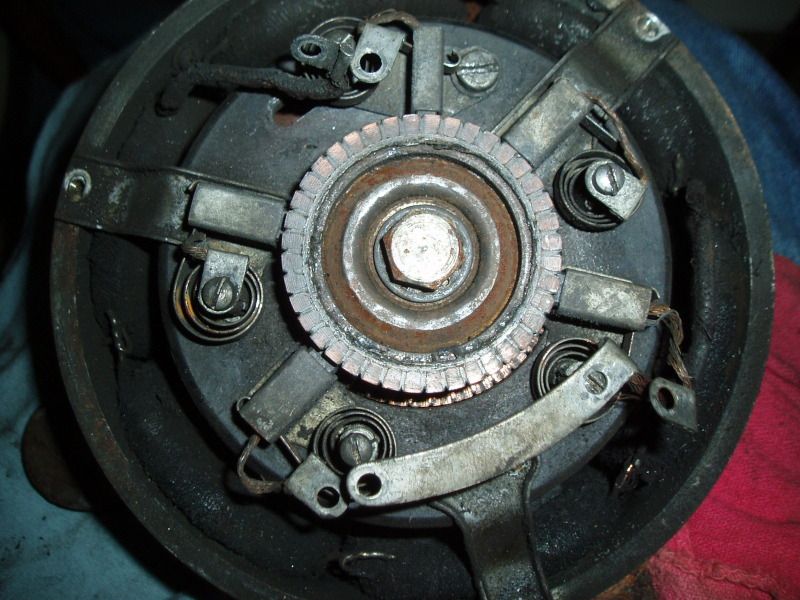

Someone sent me a powerhouse to fix. It was purchased on ebay and hadn't been used much when it quit charging. When I tested it, it showed no charge until I polarized it, but as soon as it stopped and started, it showed no charge again until I once again polarized it. Each time it started it needed to be repolarized. There was also way too many sparks coming from the brushes. Growler tests showed the armature was good, but I could see a poor job of undercutting. I used my ATLAS hobby saw to undercut it by hand and then I polished the commutator with crocus cloth. Now it works fine and the sparking is gone. What I don't like is how someone cut the commutator down. The diameter is almost 1/4" less than what it should be and this can be seen by the thin bars and the large gap between the commutator and brush holder. I think this generator came from someone in Texas and I've seen this same thing before from the same guy. Just because you're working on or restoring a generator doesn't mean it needs to be turned on a lathe. I've only had to do any cutting on the commutator a few times and that was only a few thousandths. Almost always all it needs is a polishing with fine crocus and undercut by hand so the insulation is about .010" under the bars. Due to the large gap this will now get less useful life from the brushes before the springs hit the brush holders. Plus, the larger the gap between the brush holder and commutator, the less the support for the brushes. I also don't like the looks of a thick coat of Glyptal all over the armature, and black paint on the field coils. The brush screws should also be fillister head, not round head, the external tooth lock washer on the armature should be an internal tooth lock washer, and the screw on the adjustable brush holder should be a pan head, not a round head. The bottom picture is a powerhouse I picked up last year at a swap meet. The outside is totally rust pitted, so it must have sat out in the weather most of it's life, but inside it looks like NOS, or will after I clean it off with some gas. Thankfully nobody has messed with it and that's the way I like to find them. It could actually be used just the way it is, but the rust pits on the pulley would chew up the V belt. Someday I'll move all the insides to a better case and have what I'd consider a mint powerhouse.

Last edited by Tom Wesenberg; 11-03-2012 at 01:04 AM. |

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 04:10 AM.

Threaded Mode

Threaded Mode