|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

Thread Tools | Display Modes |

|

|

#17 |

|

Senior Member

Join Date: May 2010

Location: Kalamazoo

Posts: 1,656

|

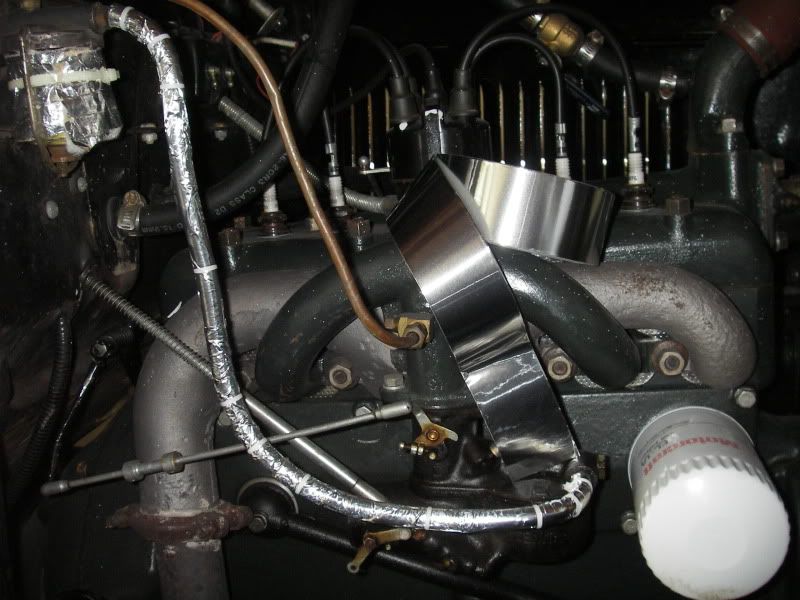

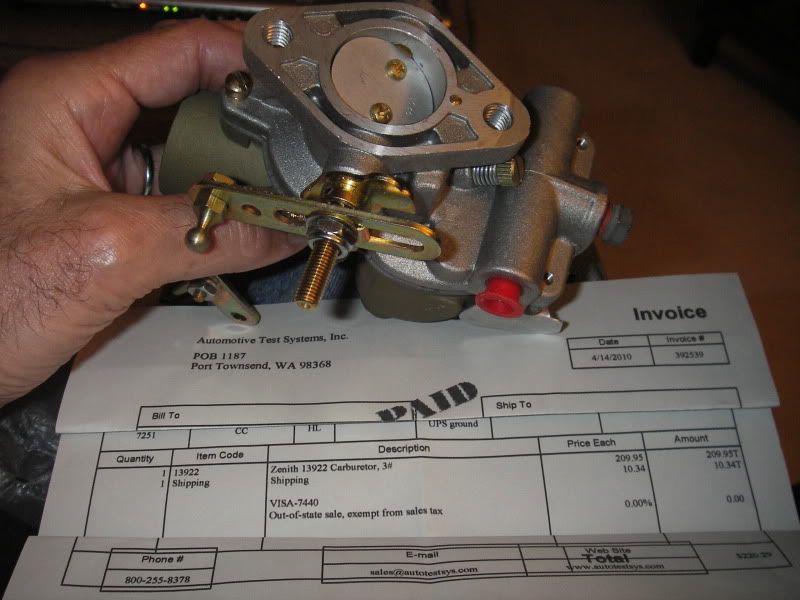

Here's picture of fuel vaporization in progress. The silvery area in the top of the sedimentation bowl is a bubble of vaporized gasoline. With the motor idling on a warm day, I could watch the bubble grow until it filled the screen surface, then the whole thing would burp out and down the fuel line, and the process start over again. The engine barely hiccupped when the bubble passed thru. Under harder running, hotter conditions, this sort of thing can happen in the line, carburetor, and any fuel filter that may have been added, which MIGHT then shut down the motor.  Here's a picture of some straws I grasped at to fight vapor lock: fiberglass and reflective coating on sed. bowl, and aluminized duct tape over rubber fuel line over metal fuel line. It helped a bit.  Here's a heat shield a buddy made and gave me after he timed his engine and didn't need it any more.  Here's what was the final solution for me. Ethanol aggravates vapor lock by what's called non-ideal mixing with gasoline of the positive deviation from Raoult's Law kind. It raises the vapor pressure of the most volatile gasoline components beyond what it would be in pure gasoline--the ethanol doesn't itself vaporize particularly easily, but it causes the gasoline to vaporize more readily than normal. The problem is further aggravated when winter blend gasoline is used in warm weather. THey don't have winter blend down south, so, paradoxically, vapor lock is less of a problem in places where it's never very cold. |

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 04:13 AM.

Threaded Mode

Threaded Mode