|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Senior Member

Join Date: Jun 2010

Location: In my machine shop.

Posts: 1,047

|

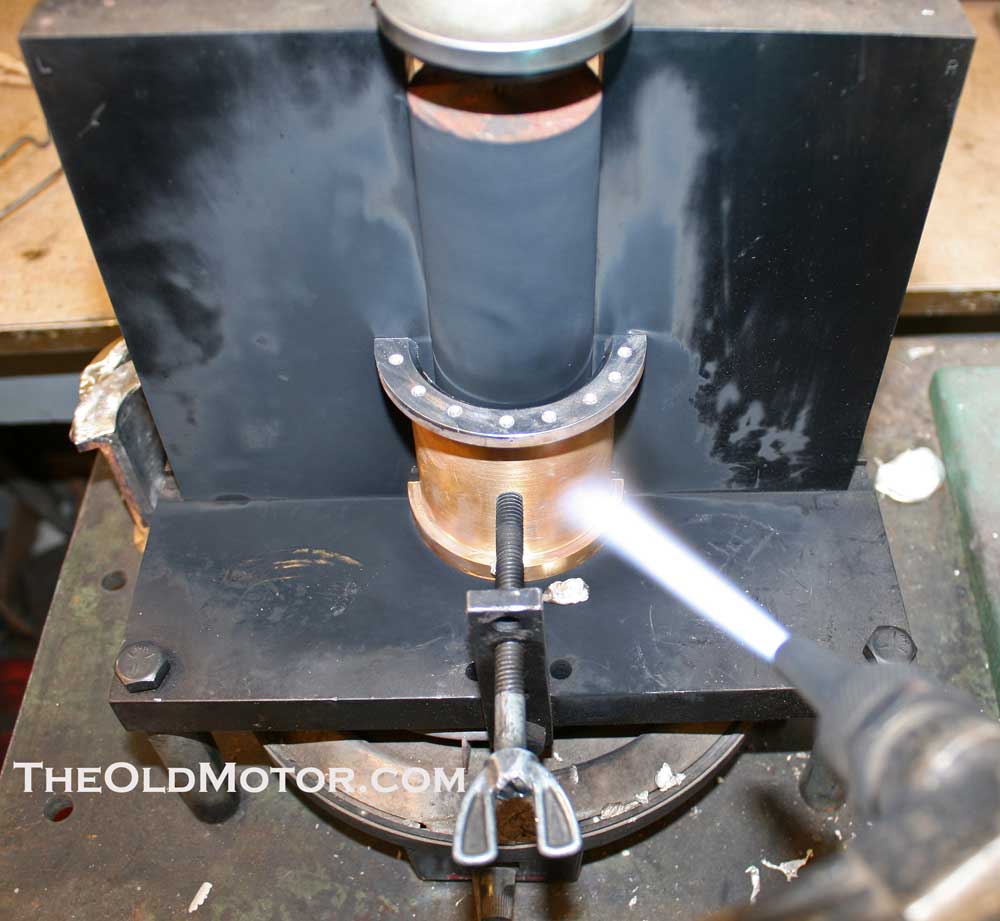

Babbitting – How it was Done During the the Early Days: We recently found this interesting three page article of how it was accomplished back in the period and featured in the "Be a Better Mechanic Series" In this interesting article you can read all about how it is poured and see the methods used in illustrations. We also have a video that shows you how it is poured against a mandrel. You might not want to try it at home, but it will at least give you a better idea of exactly how it was preformed on pre-war cars. The article is to large to post here but you can see and read it on The Old Motor.

Last edited by t-head; 12-15-2013 at 11:59 AM. |

|

|

|

|

|

#2 |

|

Senior Member

Join Date: Jun 2010

Location: In my machine shop.

Posts: 1,047

|

I seems like some of you are interested in this topic so I will keep posting things about babbitting that are interesting. We any of you have anything to add please do.

BEFORE YOU EVER EVEN THINK about trying babbitting read everything you can get your hands on and really think everything over that you have read and come up with a plan. When I first tried it I would practice on something like a T or A rod. Pour it and then bore it in a lathe quickly just to see how it looked. You also need to check the bond that you have between the babbitt and the rod or bearing shell as it is very important. The following is online and quite interesting as it gives you a good overview of how it is done. Keep in mind that you want to use a good tin-based babbitt. BABBITT AS A BEARING MATERIAL Friction & Wear When a lubricant film cannot completely separate the moving parts of a bearing, friction and wear increase. The resulting frictional heat combined with high pressure promotes localized welding of the two rubbing surfaces. These welded contact points break apart with relative motion and metal is pulled from one or both surfaces decreasing the life of the bearing. This friction and welding is most common when like metals, such as steel or cast iron, are used as bearings – they easily weld together. Compatibility of bearing materials, therefore, and absorption of lubricant upon the bearing surface, is necessary to reduce metallic contact and extend bearing life. Babbitt In 1839, Isaac Babbitt received the first patent for a white metal alloy that showed excellent bearing properties. Since then, the name babbitt has been used for other alloys involving similar ingredients. Babbitts offer an almost unsurpassed combination of compatibility, conformability, and embedability. They easily adapt their shapes to conform to the bearing shaft and will hold a lubricant film. Foreign matter not carried away by the lubrication is embedded below the surface and rendered harmless. These characteristics are due to babbitt’s hard/soft composition. High-tin babbitts, for example, consist of a relatively soft, solid matrix of tin in which are distributed hard copper-tin needles and tin-antimony cuboids. This provides for “good run-in” which means the bearing will absorb a lubricant on the surface and hold the lubricant film. Even under severe operating conditions, where high loads, fatigue problems, or high temperatures dictate the use of other stronger materials, babbitts are often employed as a thin surface coating to obtain the advantages of their good rubbing characteristics. Uses of Tin and Lead Based Babbitt Babbitt metal is used as the lining for bearing shells of cast iron, steel and bronze. Fry manufactures two basic types of babbitt: (1) high-tin alloys (2) high-lead alloys. Both are relatively low melting materials consisting of hard compound in a soft matrix. The compounds found in each group are similar; it is in the composition and properties of the matrix that they differ. High-tin babbitt is used for high unit load and high operating temperatures. They display excellent corrosion resistance, easy bonding, and less tendency for segregation and welding. They are preferred for use under steady load conditions in steam and gas turbines, electric motors, blowers, and pumps. Lead-based babbitt is prone to separate into elemental lead and tin and has a lower thermal conductivity. Users of babbitt ingot melt the metal in iron kettles from which they can ladle or pump the molten alloy. The bearing shell or backing is pre-coated with tin for tin-base bearings or with lead/tin for lead-base bearings. While the coating is still molten, the white metal is cast onto the backing and allowed to solidify from the bond inward. This prevents contraction cavities at the bond and restricts the growth of intermetallic compounds at the interface between the bearing shell and the babbitt. The lining is then machined to a mirror-bright finish and specified thickness. Babbitt can also be sprayed onto the bearing shell with the use of a flame arc gun and Fry’s babbitt wire. Changing To Lead-Free Babbitt With increasing legislative concern over the hazards of lead in the work place, more companies are interested in lead-free alternatives. There are many alloys of tin and/or lead that have been used to resist wear and support a load between contacting metallic surfaces. The selection of the appropriate babbitt has usually been a cost first, application second, decision. Frequently, a babbitt user does not know the composition of the metal they are using. Confusion abounds because the same babbitt alloy may have various trade names in different parts of the country or from one manufacturer to the next. The American Society for Testing and Materials (ASTM) has produced a specification with only eight alloys, four of which are lead-free. To help end the confusion, Fry uses the ASTM B-23 to describe babbitt alloys. The only exception is the ASTM B-23 Grade 2 Babbitt with the addition of Nickel – commonly known as ‘XXXX® Nickel Babbitt.’ The first step to switching to a lead-free babbitt is to determine which alloy is currently used. If the alloy is unknown, a sample can be analyzed by Fry’s laboratory in Altoona. Tin-based babbitts, with exception of Grade 1, are superior to all lead-based alloys. The mechanical properties of the tin-based babbitt increases steadily for Grade 11, Grade 2 and Grade 3. Grade 2 or Grade 3 can replace any lead-based alloy and show improved wear characteristics. Grade 2 is also available in wire form for flame spray metallization. Grade 11 is similar to Grade 2, but the higher copper makes alloy segregation a problem. It is much more difficult to produce a uniform alloy. This leaves Grade 2 as the preferred alternative and Grade 3 as a higher strength option. CHANGE-OVER CONSIDERATIONS 1. Lead Analysis The maximum lead allowed in a tin-based babbitt is 0.35% for Grades 1, 2 and 3, and 0.50% for Grade 11. There is no legal definition of a lead-free babbitt, although the 0.20 maximum specified for plumbing is frequently used. 2. Recycling Babbitt Customers who pour bearings are interested in reclaiming old babbitt from worn bearings. Invariably, they mix a lead alloy with new tin-based babbitt. Mixing these two causes the low melting 63Sn/37Pb eutectic to be formed. This babbitt will selectively melt out of the lining and leave a “sponge” like bearing. The 63/37 melts at 361°F and the Grade 2 babbitt does not completely melt until 669°F. A premature bearing failure is the result. A user should not mix unknown babbitts and all pots, mixers, and ladles should be free of lead. Even if the babbitt is a known tin-based babbitt, no more than 30% of a pour should be recycled alloy. A larger amount can cause excessive dross to be trapped in the casting. 3. Tinning One of the major problems in changing to a tin-based babbitt from a lead-based babbitt is the wetting characteristics. Lead will wet most metals with only a minimal cleaning, whereas, tin will not. This problem is resolved by pre-tinning the bearing. Pre-tinning is essential for the babbitt to adhere to the bearing shell. Pre-tinning can be accomplished by: (i) Dipping the shell in a pot of molten tin (ii) Wiping a metal/flux mixture onto the prepared and heated shell. (This mixture is sometimes painted on and then heated.) (iii) Abrading a tin stick to a heated and fluxed lining This came from http://www.solderworld.net/docs/babbitt.pdf Last edited by t-head; 12-13-2013 at 09:55 PM. |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#3 |

|

Senior Member

Join Date: Jun 2010

Location: In my machine shop.

Posts: 1,047

|

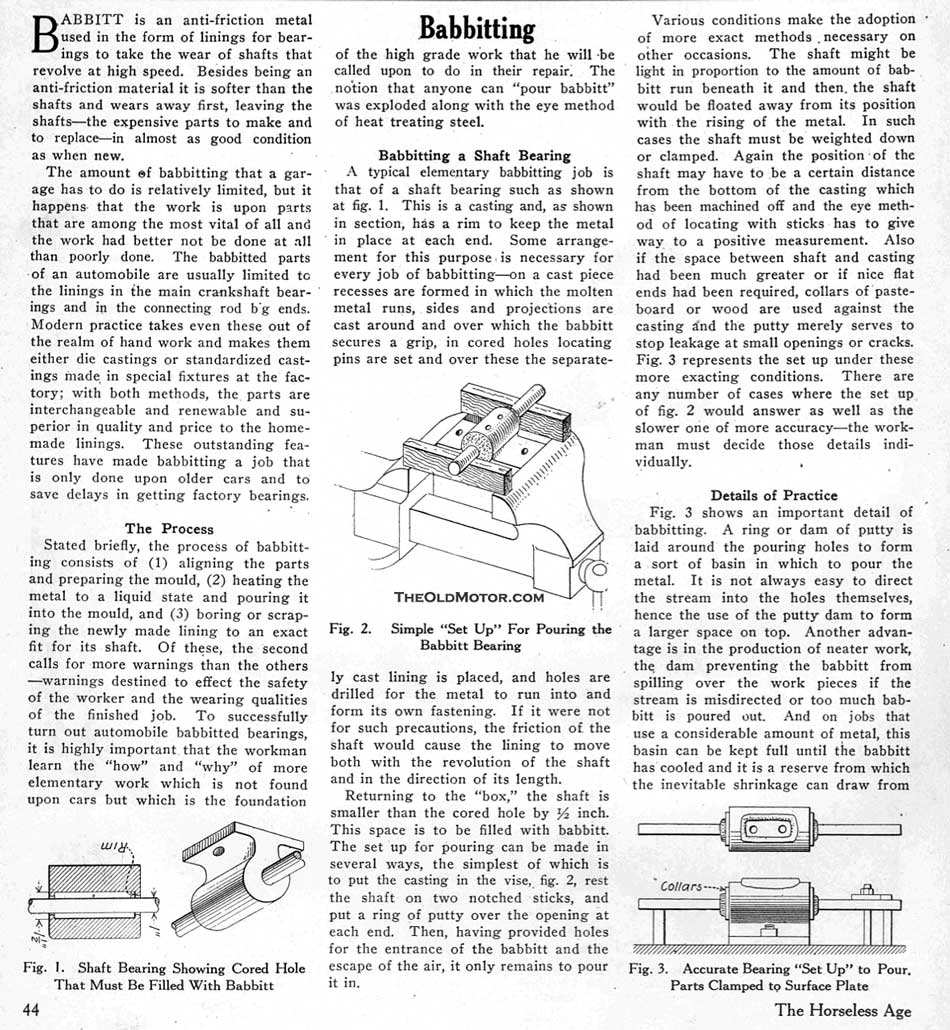

Here is one of the pages of the article at the beginning of this so you can see some of what it is about. To long to post here. The other pages are here. http://theoldmotor.com/?p=109413

|

|

|

|

|

|

#4 |

|

Senior Member

Join Date: Sep 2011

Location: Alton, NH

Posts: 1,231

|

Wow, thank you very much for posting this, and for all do for the hobby.

__________________

It's not what people think they know that will hurt them, it is what they think they know that aint so! -Mark Twain. It is the very things that we think we know, that keep us from learning what we should know.- Unknown |

|

|

|

|

|

#5 |

|

Senior Member

Join Date: Nov 2012

Location: Santa Cruz, CA

Posts: 235

|

Great info, there's a guy up north from me who I may be able to learn how to pour from. I am really interested in learning, at least to do it for myself if not for others as well.

|

|

|

|

|

|

#6 |

|

Senior Member

Join Date: May 2010

Location: Amana IA

Posts: 527

|

Sponsored Links (Register now to hide all advertisements)

I would be very interested hearing comments from the persons who do babbitt pouring. Thanks again.

__________________

Ron/IA 1929 Fordor Steelback Hawk A Model A Ford Club http://hawkamodelaclub.org/ |

|

|

|

|

|

#7 |

|

Senior Member

Join Date: Jun 2010

Location: In my machine shop.

Posts: 1,047

|

Good to here you guys are interested in it, we pour it often here in the shop and hope that others that also do will join in on this thread so that we can all learn from it....I will post more soon. We need to get some younger people interested in doing this to take over in the future.

|

|

|

|

|

|

#8 |

|

Senior Member

Join Date: May 2010

Location: Reseda, Calif.

Posts: 2,191

|

Thanks t-head. Nice article unseen by many till now. The Barn needs more info. like this. Always look forward to your post. Mark.

|

|

|

|

|

|

#9 |

|

Senior Member

Join Date: Jun 2010

Location: In my machine shop.

Posts: 1,047

|

Another interesting article from the American Machinist, December 9, 1915 issue can be seen above, where you can also learn more about the art of babbitting. The file is to large to post here but you can read the rest of the article at the bottom of the post here on The Old Motor. |

|

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 12:31 PM.

Linear Mode

Linear Mode