|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Senior Member

Join Date: Aug 2012

Location: South East Wisconsin

Posts: 1,283

|

Hi guys: I was working on the distributor this AM off my 28 business coupe. The car hadn't been run since 1955. I bought it last summer and finally am getting aound to doing somthing with this car. I had to take the shaft out because it was really difficult to turn. Dry grease. After oiling the thing, it turned well and was nice and snug in the bushing, so I went farther than I had ever gone before.

I drilled out the upper portion of the distributor shaft for oiling. 1/8" hole down the top about 5/16" below the upper ridge, and a corresponding hole into the side of the shaft 5/16" below the ridge so that the resulting oil passage connects. Then I drilled out the rotor screw, so that the upper bushing can be oiled without removing the rotor screw. Tested the arrangement and found that oil passes through just fine. Also tested the existing oiler to make sure the lower bushing gets oil. Also was OK. I replaced the lower distributor shaft connector rivet pin with the correct size nail cut to length. Nails rivet over well. This only took a little longer than it takes to order a new predrilled shaft from one of our supppliers over the phone, and I'm no machinist by any stretch. You only need a drill press with a sharp 1/8" bit. Thanks |

|

|

|

|

|

#2 |

|

Senior Member

Join Date: May 2010

Location: Mpls, MN

Posts: 27,582

|

The top bushing will get oiled if the distributor is oiled as it should be.

I liked to buy the stock shaft with no added oil hole, but I don't think they are being sold anymore due to the belief that the top bushing must be oiled from the top.

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#3 | |

|

Senior Member

Join Date: Aug 2011

Location: Illinois

Posts: 741

|

Quote:

Don't be sad.  I believe Snyder's still stocks both flavors of this disti shaft. The original is listed as p/n A-12178-S. |

|

|

|

|

|

|

#4 |

|

Senior Member

Join Date: May 2010

Location: Southern California

Posts: 3,168

|

While you have the distributor out of the car remove the little spring loaded oiler and shine a light into the hole to see if you can see the shaft. Many of these distributors that have sat around for years have the hole totally plugged with crud. Use a 1\4" drill bit to clean the crud out of the hole.

Tom Endy |

|

|

|

|

|

#5 |

|

Senior Member

Join Date: May 2010

Location: Mpls, MN

Posts: 27,582

|

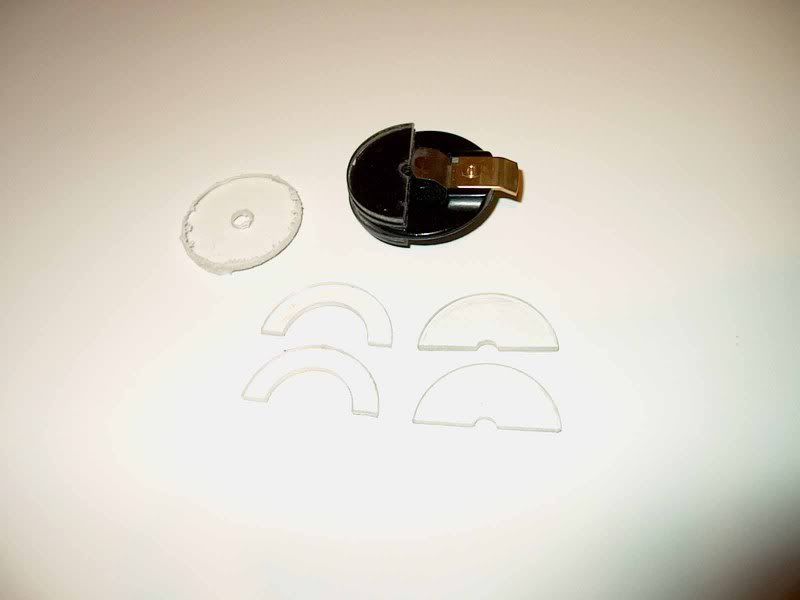

Here's how I remove the oiler. I do this before the sandblast, but had to pose this for the picture. As Tom said, it's often plugged solid. I like to use original parts and rebuild them as original. I have some 160 strand wire, which is very flexible for the lower plate. I also like to balance my rotors. If you mount a rotor to the cam and shaft only, then stick it in a small electric drill and spin it at 1000 RPM, you can feel what the top bushing feels from an unbalanced rotor. |

|

|

|

|

|

#6 |

|

Senior Member

Join Date: Aug 2012

Location: South East Wisconsin

Posts: 1,283

|

Sponsored Links (Register now to hide all advertisements)

|

|

|

|

|

|

#7 |

|

Senior Member

Join Date: Aug 2011

Location: Illinois

Posts: 741

|

Wow !

I would have never thought to dynamically balance the disti rotor but it makes good sense. Doesn't seem to be that much weight or mass to worry about on this scale. I do know that later disti rotors often look to be more oblong in shape probably for this reason to achieving better balance. How did do you balance it? Did you attach the plastic piece and keep removing extra stock until it felt balanced in your drill? Tom can you go into some more detail on your improved rotor set up? I would like to try it out. Thank you. |

|

|

|

|

|

#8 |

|

Senior Member

Join Date: May 2010

Location: Mpls, MN

Posts: 27,582

|

I used my hole saw kit to cut some 1/8" plastic into circles. I cut them in half and used super glue to glue them to the rotor. After a couple years one of the plastic pieces let go and messed up my rotor, so I used some 1/4" fiberglass rod to secure the pieces. I don't use plastic now, but grind away the plastic on the sides of the brass, then drill a couple holes and add a couple small screws and nuts to balance the end opposite the brass. I use the small ball bearing balancer to balance the rotor. You could also use a table edge to balance. When the heavy side stops at random places, then it's in balance. |

|

|

|

|

|

#9 |

|

Senior Member

Join Date: May 2010

Location: Camino, CA.

Posts: 3,086

|

Does anyone else balance their rotor? I've never heard of that. Some vendor should start making balanced ones. Sounds like overkill to me.

|

|

|

|

|

|

#10 |

|

Senior Member

Join Date: May 2010

Location: on the Littlefield

Posts: 6,555

|

I have a totally stock dist --the last time I oiled it I gave it a good squirt with the oil gun, a few months later I had the cap off and could see that oil was coming out the top bushing---enough to also oil the center bearing of the point plate, ---with a stock setup using quality proper bushings no xtra oil is needed,

|

|

|

|

|

|

#11 |

|

Senior Member

Join Date: May 2010

Location: Oregon

Posts: 1,462

|

While we are on this discussion, it would be good to mention a design flaw of the Model B distributor, which has a shorter casting but the same size internal bushings. The result is that the drilling for the oil hole is blocked by the bushing and so no oil gets to the shaft. At first I thought this was a fluke, but I have since been told that the vast majority of them came that way in the beginning. I now pull the oil filler and drill through the bushing with a 1/8 inch bit to make an opening, then install the shaft. They fit tight much longer that way.

|

|

|

|

|

|

#12 |

|

Senior Member

Join Date: May 2010

Location: Mpls, MN

Posts: 27,582

|

Here is a picture of the first balancer I made. The two parallel bars must be level for this style to work. I've used this and the ball bearing style to balance fans and distibutor rotors. Just like crankshaft counterweights help the life of babbit, a balanced rotor helps the life of the top bushing, and if there is any play in the top bushing, a balanced rotor helps to maintain points opening and timing. Think about the wobble caused by a heavy side and play in the bushing. When the heavy side is towards the points it will make the points open wider and the timing will be advanced some. When the heavy side is away from the points, the points will open less and the timing will be later. With a well balanced rotor the points spring pressure will always be pushing the rotor away and the opening and timing should be consistent. I turned an old distributor shaft down on one end so I could chuck it into a 1/4" drill and run it at !,000 RPM. This is the same speed as the car driving about 40 MPH, and with an unbalanced rotor the drill had considerable shake. |

|

|

|

|

|

#13 |

|

Senior Member

Join Date: Aug 2011

Location: Illinois

Posts: 741

|

Tom,

Thank you for the knowledge you are sharing here. It is certainly appreciated by me. I have always enjoyed doing mini tweaks to my Model A's to make them just a little bit faster or dependable. I think I will try to modify a rotor or two using your balancing ideas. Just recently I had rebuilt a couple of Model B distis and finally put one on one of my cars. I also noticed the blockage from the oil filler into the bushing and I did drill through it. I assumed so previous owner had rebushed improperly. I used trial and error with a timing light to get it timed running at TDC. I left the side adjustment plate at dead center and did not adjust it. I gave my car the acid test of driving up a steep local hill where I would normally have to retard the spark. I was really pleased with how the Model B disti handled this hill. It had smooth power going up it and at higher speeds. I am not sure if I will keep it on the car as I sort of missed playing with the spark while driving. It was a fun restoration project that kept me out of the bars for a couple of days and I got my feeling of accomplishment when it ran well. Steve at Bert's also says that most Model A drivers would not be happy running with a Model B disti if you are driving in the mountains.....

|

|

|

|

|

|

#14 |

|

Senior Member

Join Date: Aug 2012

Location: South East Wisconsin

Posts: 1,283

|

I just chucked an old distributer shaft, points cam and rotor in my 1/2" drill and spun it up to the maximum 850rpm. Yup. There is some wobble. I could actually feel it. So rotors are out of balance from the factory because the steel pinter is only on one side and not counter balanced. Dave: Stick one of yours in a drill and try it and see what you think.

mike |

|

|

|

|

|

#15 |

|

Senior Member

Join Date: May 2010

Location: on the Littlefield

Posts: 6,555

|

On a distributer machine with or without the ritor doesn't make much difference in vibration, but I did notice something interesting, the dist I tried was as removed from an engine that had been sitting, I had oiled the shaft because it was stiff to turn as removed but had done nothing to the points, at 1000 dist rpm the pattern on the machine broke up to point bounce, then at higher speeds went back to normal --then I lubed the dist cam, the point bounce went away ---after lubing the old points and with original "a" cam gave good point action to over 5000 engine rpm, with both dwell and pattern steady.

The dist with repro plate, modern points, modern repro b style cam(not a quality Stipe cam) had trouble keeping a constant dwell and timing pattern at all speeds My dist machine is a Marquett, not as good as a SUN or Allen, the mounting holder is it's weakness and a dist with a bent shaft or balance problem vibrates horribley, the original A rotor hardly made a difference on or off in the normal operating range of the engine (up to 3600 eng rpm), I don't clamp the dist direct, I use the A connecting shaft so the dist is driven the same as in the car |

|

|

|

|

|

#16 |

|

Senior Member

Join Date: Aug 2011

Location: Illinois

Posts: 741

|

I was thinking about this balancing of the disti rotor all day. I really do need a life outside of tinkering with Model A's.

Anyway.... As a "Quick Farmer Fix" what would happen if you drilled a ~ 1/4 " hole in the metal blade on the rotor where it wouldn't harm the structure. It probably would not affect the strength or the electrical capacity of the rotor to make the spark connection. It should reduce the mass on that side of the rotor somewhat getting it closer to being in balance. It would not be perfectly balanced but should be better then original. I know Guru Bill likes to drill holes in his Model A's so he may have an idea or two here. I may just try it as I would be curious as to if it will then make my Model A able to whistle Dixie.... Any thoughts on this Pro or Con ?????????? |

|

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 07:22 PM.

Linear Mode

Linear Mode