|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Junior Member

Join Date: Jan 2018

Location: St. Charles, Missouri

Posts: 29

|

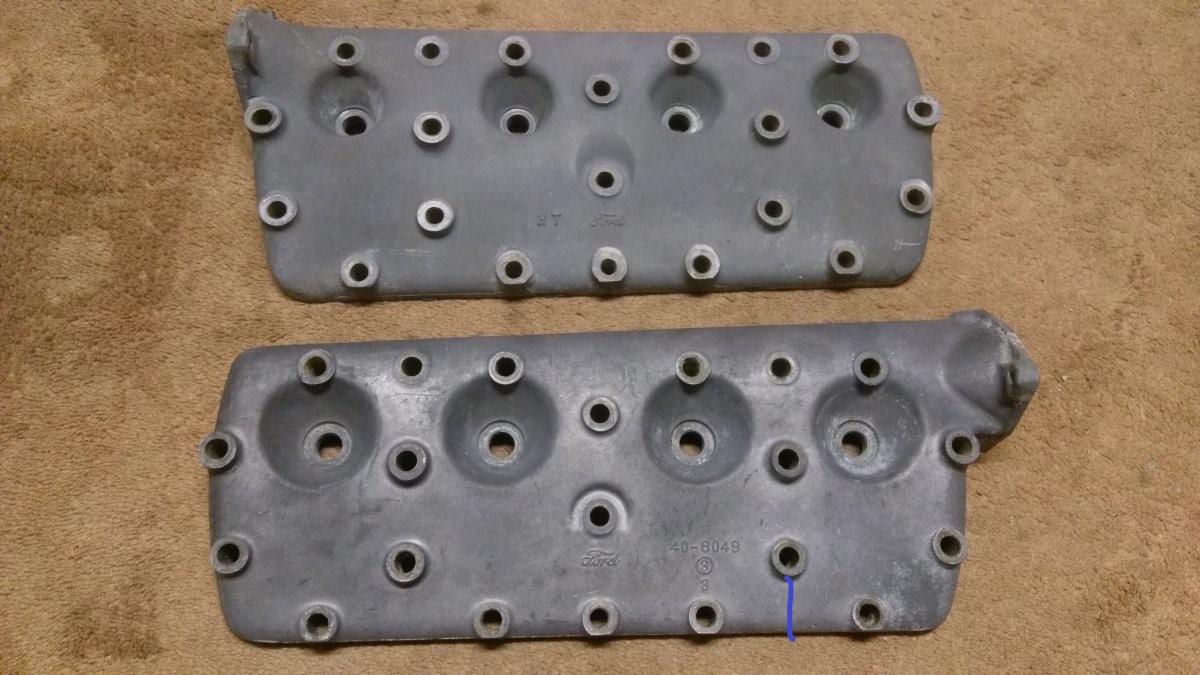

I have to repair as small crack in one of my aluminum heads on the 35 ford coupe. Can someone tell me if those heads were originally factory painted along with the rest of the engine?

|

|

|

|

|

|

#2 |

|

Senior Member

Join Date: May 2010

Location: Southern France

Posts: 5,837

|

No paint from the factory.Commercial applications which were cast iron were painted.

Last edited by deuce lover; 10-31-2018 at 07:47 AM. |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#3 |

|

Junior Member

Join Date: Jan 2018

Location: St. Charles, Missouri

Posts: 29

|

|

|

|

|

|

|

#4 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

Depending on where the crack is there could be additional issues. If there is a lot of corrosion inside/behind where you are attempting to weld it will not react well to the heat of the weld. It is possible to end up with a bigger problem.

|

|

|

|

|

|

#5 |

|

Senior Member

Join Date: Dec 2013

Location: Minnesota, Florida Keys

Posts: 11,633

|

I bought some special high strength aluminum epoxy on Amazon and used it to repair some broken bolt bosses on a Navarro Universal intake manifold. Two years down the line, it's still holding. I don't know if it would work on heads; just suggesting a possible alternative to welding, which, as "JSeery" said, can make a big problem out of a little problem quite quickly on old aluminum castings.

|

|

|

|

|

|

#6 |

|

Junior Member

Join Date: Jan 2018

Location: St. Charles, Missouri

Posts: 29

|

Sponsored Links (Register now to hide all advertisements)

|

|

|

|

|

|

#7 |

|

Member Emeritus

Join Date: Nov 2012

Location: Wichita KS

Posts: 16,132

|

IMO I would reconsider the welding option, it would be a shame to destroy that nice of a head. But that is just me.

|

|

|

|

|

|

#8 |

|

Junior Member

Join Date: May 2021

Posts: 1

|

I have the same similar issue with my aluminum head made in Canada, "cheater heads" I'd like to repair them. Let me know what you ended up with and give me some pointers. It's on the water side.

|

|

|

|

|

|

#9 |

|

Senior Member

Join Date: Jan 2011

Location: Central Ohio

Posts: 5,723

|

Does the crack go through into the stud hole? If so, then things will get a lot more difficult as the stud-hole would need to be sleeved with aluminum to seal it.

Another option is to use a 'water glass' type product (Moroso Ceramic Seal is what I use). If you're just weeping water out of the current crack, this will seal it. Pay attention to the directions! If it was mine, I'd probably have it welded and then vapor blasted or light glass beaded to try to get the whole surface to look pretty much the same. If you weld on it, it can warp the head deck surface as well - so then it may need to be surfaced. Just something to note . . . |

|

|

|

|

|

#10 |

|

Senior Member

Join Date: May 2010

Posts: 453

|

Bars Leak? I had a crack on a 37 cast iron head. It sealed itself.

|

|

|

|

|

|

#11 |

|

Senior Member

Join Date: May 2010

Posts: 5,187

|

There is a description of the 35 heads on the early Ford V8 club web site under edits to the 35-36 restoration book. Your heads appear a bit earlier than 35.

|

|

|

|

|

|

#12 |

|

Senior Member

Join Date: Nov 2020

Location: SW WA

Posts: 693

|

I have welded several of these heads. They weld just fine, just make sure it's perfectly clean and "V" the crack. I will then weld, peen, sculpt/sand the weld and retexture the area and you can't tell where the repair was made if it's done correctly. Sometimes preheating is necessary. Also, make sure to use the correct filler rod.

I have a big abrasive sander specifically for decking automotive heads or whatever else needs to be made flat again. This is perfect for making a head flat again, or to just check if a head is flat. It's always good to check this, especially after any repairs. I think repairing it right the first time is the best practice. If you are unable to do the work, find someone competent that can. There are lots of qualified folks out there. Good Luck! Last edited by OldGold360; 08-22-2024 at 10:50 AM. |

|

|

|

|

|

#13 | |

|

Senior Member

Join Date: Jan 2011

Location: Central Ohio

Posts: 5,723

|

Quote:

|

|

|

|

|

|

|

#14 | |

|

Senior Member

Join Date: Mar 2014

Location: Jacksonville FL

Posts: 4,806

|

Quote:

|

|

|

|

|

|

|

#15 |

|

Senior Member

Join Date: Nov 2020

Location: SW WA

Posts: 693

|

4043 works for most vintage cast aluminum. As far as adding the texture back... it depends on the type of texture. Some textures are more rough than others, and casting material does not always respond the same way each time. Almost like some castings are harder than others. Softer castings are easier to get a good texture than harder castings. There are several techniques and it usually requires reading the materials and applying the correct technique, or many techniques, to achieve the desired results. It would be much easier to show someone than to explain it all.

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 12:52 PM.

Linear Mode

Linear Mode