|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Senior Member

Join Date: May 2010

Location: Regina Canada

Posts: 1,334

|

looking for pros and cons of steel center main vs the bolt on strap. Will be for a Paxton blower motor 276 cu. in. Thanks Bill

|

|

|

|

|

|

#2 |

|

Senior Member

Join Date: Jul 2010

Posts: 2,593

|

Strap is cheap and easy to fit, steel main cap will need Line boring, not cheap.

Plenty of built flatheads out there with the strap. How much pressure and abuse is the engine really gonna see? Those centrifugal blowers don't have the low end thump of power off idle like a rootes blower, there generally more gentle build of power higher up. Martin. |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#3 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,854

|

I waz gong to say the same thing, strap, properly installed should be good for 5lbs. Have a 294 going together with a Magnason blower and a strapped center main, so we'll find out.

|

|

|

|

|

|

#4 |

|

Senior Member

Join Date: May 2010

Location: Qld, Australia

Posts: 4,210

|

We ran a 258 cu in engine in our dragster for a couple of seasons,Hilborn injection,no blower ,all stock 8ba stuff in the engine ,including the main caps,no strap,ran it up to 5700rpm, no worries,

Lawrie |

|

|

|

|

|

#5 |

|

Senior Member

Join Date: May 2010

Location: charlottesville, Va.

Posts: 589

|

You won't have any trouble with the strap until you get over ten pounds of boost,

|

|

|

|

|

|

#6 |

|

Senior Member

Join Date: May 2010

Location: Regina Canada

Posts: 1,334

|

Sponsored Links (Register now to hide all advertisements)

|

|

|

|

|

|

#7 |

|

Senior Member

Join Date: Jul 2010

Posts: 2,593

|

That seven pounds is just guess work, not an accurate number. The amount of boost pressure in any engine is dependant on lots of things, tis only a ball park figure. You have to measure the pressure on the engine it's gonna live on. So be sure to fit a pressure guage to see what your actually getting. If it goes to high your heading for expensive parts bills.

Out of interest what's the rest of the engine spec? Martin. |

|

|

|

|

|

#8 |

|

Senior Member

Join Date: May 2010

Location: Michigan

Posts: 464

|

|

|

|

|

|

|

#9 |

|

Senior Member

Join Date: Jul 2010

Posts: 136

|

I have a 286" blown flathead running 5 Lb boost built by MCF. His main cap was unique as he incorporated a flat surfaced, pivoting cap on the end of the bolt and also machined a flat spot on main bearing cap. This eliminates any "point loads" on the bearing cap and ensures the pivoting cap on the bolt seats flat on the machined surface. The engine has 25,000 miles now with no problems.

|

|

|

|

|

|

#10 | |

|

Senior Member

Join Date: May 2010

Location: NJ

Posts: 6,177

|

Quote:

|

|

|

|

|

|

|

#11 |

|

Senior Member

Join Date: May 2010

Location: Long Island, NY

Posts: 1,052

|

Just a tip, we were never comfortable with that main strap setup. The center main section of these blocks is an extremely weak area. It doesn't take much to literally rip it out of the casting. If you examine the block you will see what I'm saying.

It is already tensed up by the main bolts/studs. It sees much of the internal stresses of the rotating ass'y. While the 4 center cylinders are in the firing cycle the loads are extremely high on that main, moreso when it is on a blown platform! This "strap-the-caps" deal was a fairly common procedure years ago on the Chev's also, never agreed with it back then on those either. The best way to add add'l support to that entire area is a "girdle" that straddles the center cap and ties the block together at the pan rails. We've done many this way, unfortunately I have no more of these girdles in inventory. If you talk to your builder he MAY be tempted to give it a try, making it from scratch?? It is a little time-consuming but not that difficult, it could be made on a conventional Bridgeport! While we were using these, the way we programmed the part, it wasn't necessary to either line-bore OR line-hone, we made it fit minus both these procedures. Worked really well. (Add) It also allowed the stock pans to remain, no pan modifications at all. Thanks, Gary in N.Y. P.S. Here's a shot of the pattern only, it is as thick/wide as the center cap and the side bolts did not hit any water! It was a nice setup at the time for us. I had made about 20 of them, used most, eventually sold the others.

__________________

http://www.stromberg-bulletin.com/me...berg-equipped/ |

|

|

|

|

|

#12 | |

|

Senior Member

Join Date: May 2010

Location: NJ

Posts: 6,177

|

Quote:

Hi Gary: Seems like a well thought out piece. Curious, why did you stop and would you ever consider making more? Thanks, Tim |

|

|

|

|

|

|

#13 | |

|

Senior Member

Join Date: May 2010

Location: Eagle River,Alaska

Posts: 352

|

Quote:

|

|

|

|

|

|

|

#14 |

|

Senior Member

Join Date: Jul 2010

Posts: 2,593

|

Garry, does your girdle fit over the stock main cap?

Martin. |

|

|

|

|

|

#15 |

|

Member Emeritus

Join Date: May 2010

Location: Fitzgerald, Georgia

Posts: 2,204

|

Another bad idea. The center main web CAN break out of the block. So, let us drill and tap more holes in it to help that process along.

Of the commercially available systems only that which requires extensive pan modification(like King's) and bolts to most of the pan rail length could be considered an improvement in rigidity and cycle resistance. |

|

|

|

|

|

#16 | |

|

Senior Member

Join Date: May 2010

Location: Wa.

Posts: 5,403

|

Quote:

|

|

|

|

|

|

|

#17 |

|

Senior Member

Join Date: May 2014

Location: Lafayette, La.

Posts: 100

|

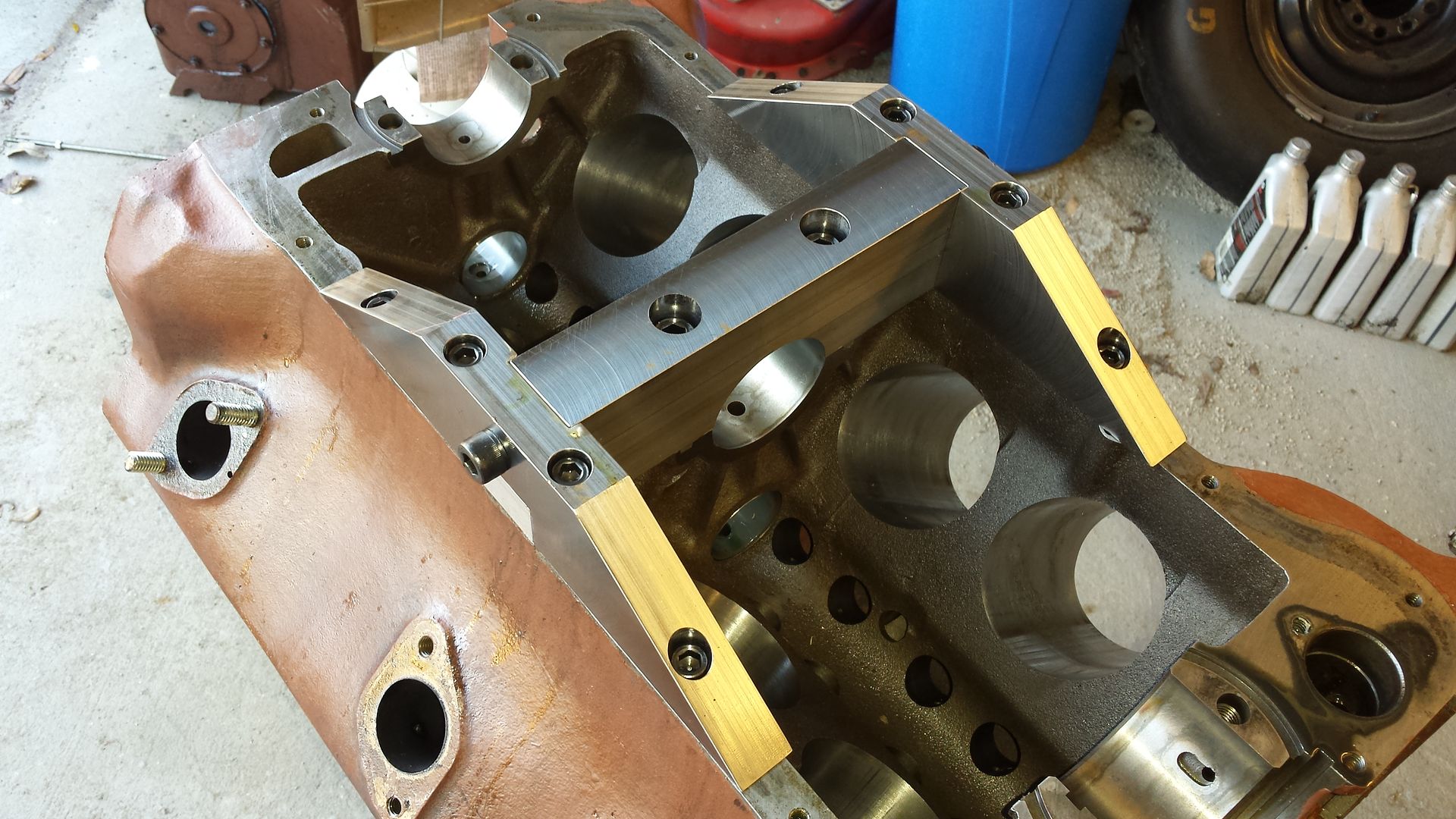

had this made up by a local CNC shop.

|

|

|

|

|

|

#18 |

|

Senior Member

Join Date: May 2010

Location: Eagle River,Alaska

Posts: 352

|

|

|

|

|

|

|

#19 |

|

Senior Member

Join Date: May 2010

Location: (Not far enough...) Outside of DC

Posts: 3,387

|

Hi Everyone, Can I add some questions?

What kind of oil pan would that use? How would it attach? Of course, that girdle stays on there when the engine is running, right? My mind is having a hard time turning that picture into a running engine.

__________________

-Jeff H Have you thought about supporting the Early Ford V-8 Foundation Museum? |

|

|

|

|

|

#20 |

|

Senior Member

Join Date: May 2010

Location: Eagle River,Alaska

Posts: 352

|

Yes the girdle stays there. You have to modify the oil pan. I have a friend here that did this with a girdle he bought when King was making them. On his though I seem to remember the girdle came drilled & tapped for the oil pan holes

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Thread Tools | |

| Display Modes | |

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 07:21 AM.

Linear Mode

Linear Mode