|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

Hey guys new to posting to the ford barn. 25 years old from Pittsburgh.

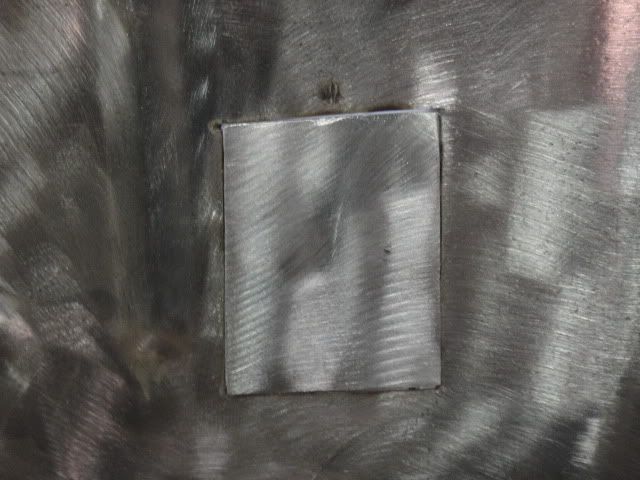

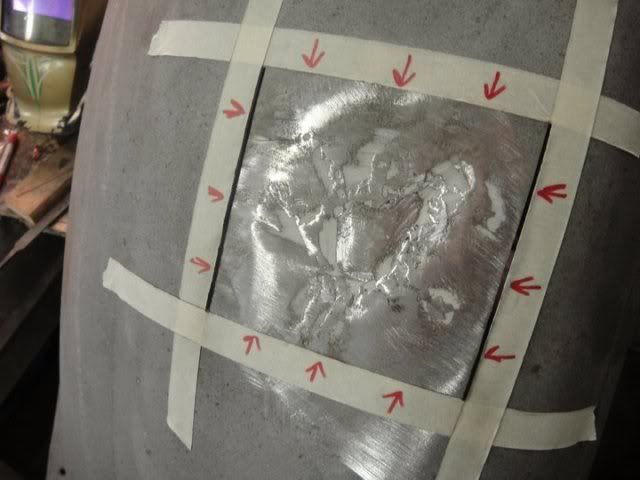

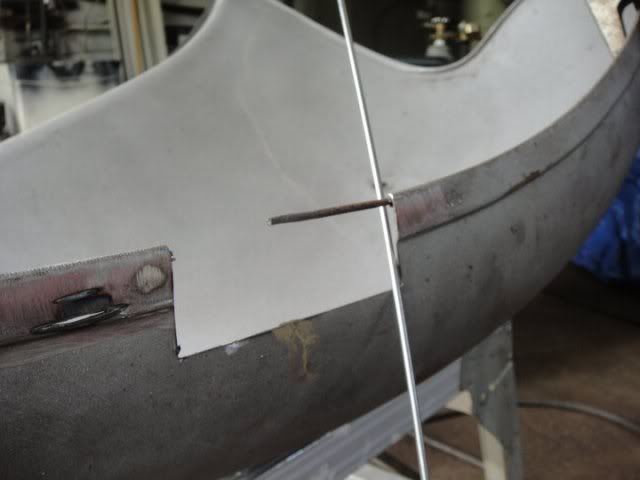

Customers car. He wants it all stock. Just figured you guys would enjoy some sheetmetal work and the fiasco of new patch panels that i am going through. All the sheetmetal work is tig welded and as close to metal finished as possible.  needs typical patch panels but man is this car solid mess    needs some sub frame work  gotta fix this hole.seems like ti was made with a chisel  tight gaps are important  see what i mean by tight?! see that little slit   this is gonna be a pain in the ass!!  the ol tape and bondo trick  fillin some random holes   some holes in the visor    some kinda mess from ages ago

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 07-07-2012 at 05:38 PM. |

|

|

|

|

|

#2 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

and we are donnne

my guess was an antenna?     more random taped up holes i found.   some more damage   a few marks left from the stud gun     these are gonna be no fun. body line doesnt match to save its life

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 09-06-2011 at 08:41 PM. |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#3 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

1 thing i learned is you can really beat 16 gauge sheetmetal.

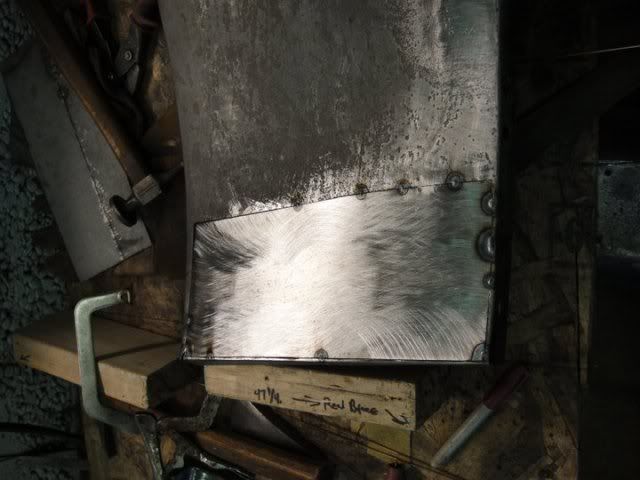

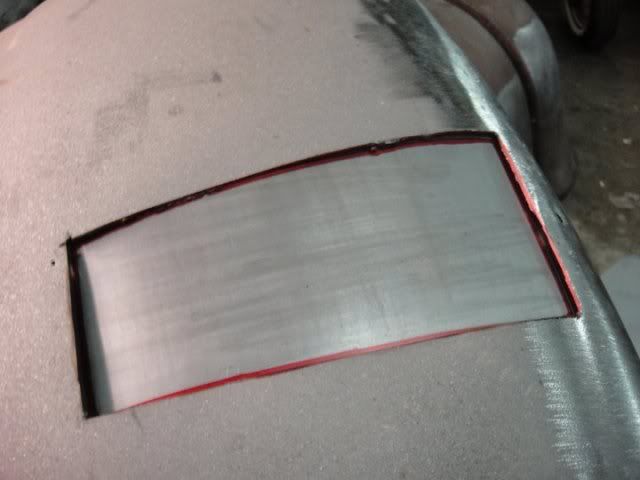

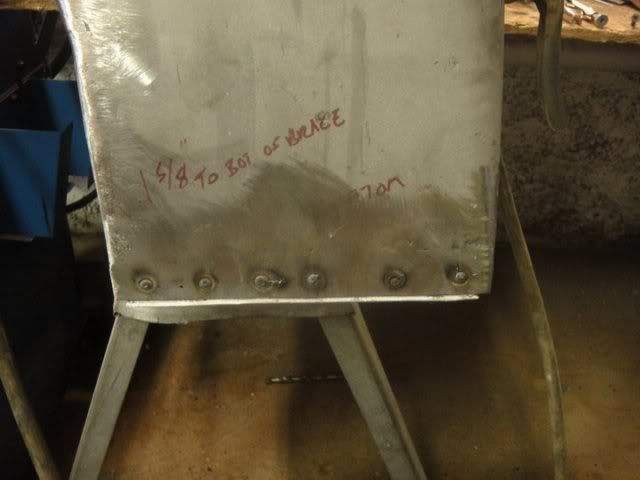

heres another poorly made non fitting heater hole patch panel.  the mess im working with  fit  notice the extra 1/8 inch of bead  the blue line is how wide it should be.i hammered the hell outa the area on the other side of the blue line to flatten it out so the beads matched   the bottom piece was really no fun     what i ended up with

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 09-07-2011 at 06:46 AM. |

|

|

|

|

|

#4 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

i really have no idea how it came out this clean but hey im not complaining!!

next im onto the patch panels...joyyyy!!

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 09-07-2011 at 06:58 AM. |

|

|

|

|

|

#5 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

wheel well time. customer decided to put the patch panels we had in for the wheel wells

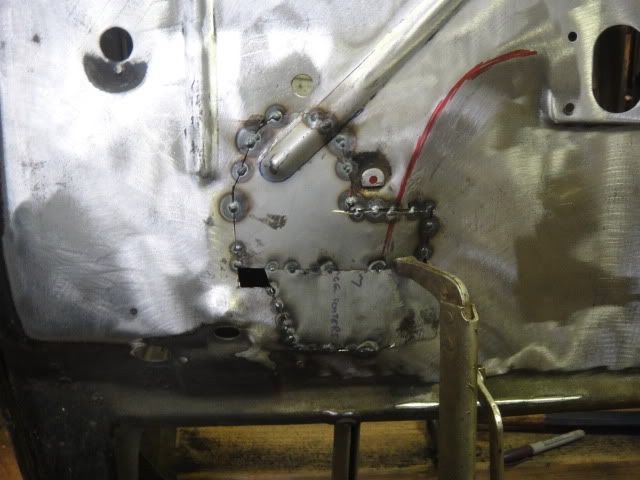

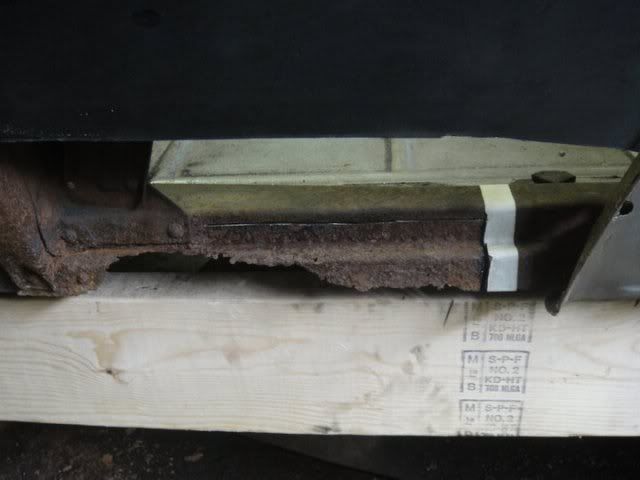

trim trim trim mess mess mess  subframe cracked and thin   cut it out!  patch  look mom no clamps!!! got a nice tight fit   welded up  didnt get a pic of the bottom trimmed down  doneeee  onto the wheel well next

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 09-07-2011 at 07:25 AM. |

|

|

|

|

|

#6 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

Sponsored Links (Register now to hide all advertisements)

some primer on the subframe and some weld-through primer on the lower part of the patch because i dont know if the patch gets spot welded to the subframe once ya wrap it around or not.  tacked in . i usually dont work with that many tacks but for this one it seemed impossible not to. there were alot of variations in where the patch panel wanted to sit and where the og wheel well was so a ton of tacks it was   finished up!  for future reference it took a little more then 18 feet of tig rod to weld in the patch haha  another view

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 09-07-2011 at 07:31 AM. |

|

|

|

|

|

#7 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

Next side

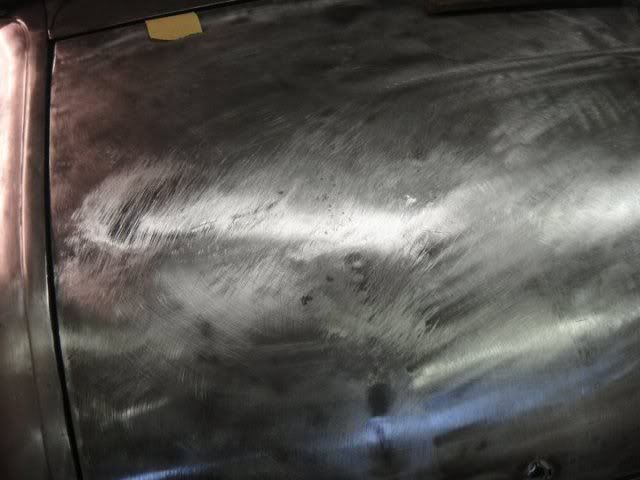

more subframe rusty-ness   new piece of subframe with some shrinker stretcher action to mimic the stock piece  sitting in place finished up the sub-frame welded up and primed. it was a fun piece to make with the curve in it  this quarter was pretty tweaked. Hard to see if the pic it took a good hit at one point   file hammer repeat to infinity  came out pretty nice the body line still need work  the quality of the panels hahahah  and we are tacked in

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 09-07-2011 at 11:22 AM. |

|

|

|

|

|

#8 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

decklid

someone had a dance on this thing!!   most of this was stud gun work mostly all the dents were behind braces. and some shrinking hammer here and there about half way through   its not 100 percent metal finished but its pretty damn nice in my book

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 09-08-2011 at 07:48 AM. |

|

|

|

|

|

#9 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

got the patch panels from macs in the mail today. JUNK! same as the other ones just on a better piece of metal.

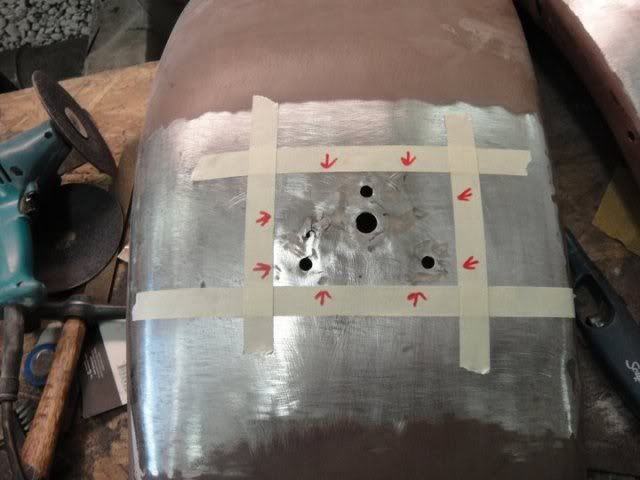

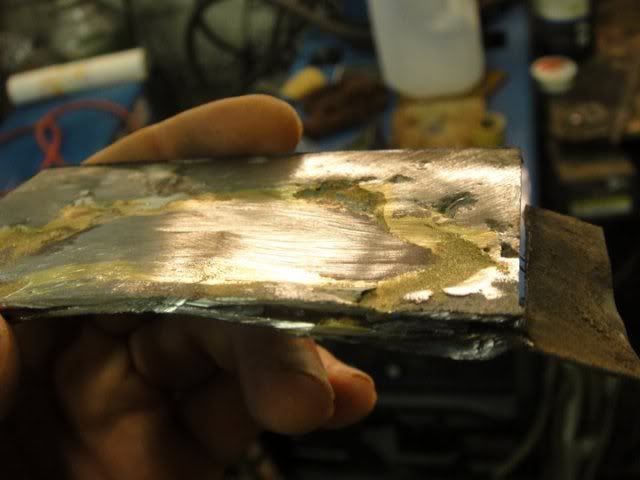

so it needed more subframe work nothing fancy or pretty here     heres the og piece of body line i have to re weld in after fixing the subframe.gonna keep as much of this around as possible because aparently it is impossible to remake .  im making my own panels now. so far i have a much nice start then what i got as a patch panel. i used a piece of 20 guage for the first run just to see what i could make it do and i like the results. switich to 18 gauge for the final product. i used my commie bead roller some conduit and bruce springsteen on the ipod. wish i woulda started working on these in the begining of the day instead of messing with the patch panels. i made this up in about 20 mins and quite happy once i get the hard line from the step die out i think ill be good to go   you can see i started to get the hard line out on the edge. pretty excited about this!!

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 09-08-2011 at 07:54 AM. |

|

|

|

|

|

#10 |

|

Senior Member

Join Date: May 2010

Location: Eastern Tennessee

Posts: 11,509

|

Nice work and nice narrative (--albeit a little crude with some of the unnecessary foul language!!!). Thanks for sharing.

You are correct that in most instances the commercially available patch panels are indeed junk. While I did not see it mentioned, I am sure you also found those inner fender patches did not have the correct shape stamped into them, nor is the beads like the originals. Truly sad for all the effort that goes into this area. I'm sure that you will probably fabricate those next time too just so you can make them look closer to original. I guess that is why they say "experience is something you get after you need it!"  Next time your experience will let you be able to tell the customer that he will need to let you make them yourselves!! Next time your experience will let you be able to tell the customer that he will need to let you make them yourselves!!  On a side note if you don't mind me asking, did you do this project on a 'Time & Materials' cost to him, ...or did you quote a turn-key price for the whole project beforehand, --and if so, would you do it for the same price again now that you know what all was involved?? Again, nice job & thanks for sharing. (...and BTW, I could not get your website to open.) . |

|

|

|

|

|

#11 |

|

Senior Member

Join Date: May 2010

Location: Eastern Tennessee

Posts: 11,509

|

Update; kept trying and it finally opened so there must have been some cyberland issues due to 'cold weather'!

. |

|

|

|

|

|

#12 |

|

Senior Member

Join Date: May 2010

Location: Grafton,OHIO

Posts: 727

|

Hats off to you on the work.Just glad im not footing the bill. RAY

|

|

|

|

|

|

#13 |

|

Senior Member

Join Date: May 2010

Location: South East NJ

Posts: 3,398

|

You clearly do nice work, but I have a question.

Why did you do the whole wheel well patch? There was only a little bit of metal at the bottom that was bad. From my experience it is fairly quick to make and weld in a a patch at the bottom of the wheel well. When you consider the length of the weld to do the whole arc and the cost of the panels. In the end I think you use less time and materials to make your own patch and weld it in. I have encouraged several other people to make their own patches. In each case they have been surprised with how easy and quick the job went. |

|

|

|

|

|

#14 |

|

Senior Member

Join Date: May 2010

Location: new britain,ct 06052

Posts: 9,390

|

WOW! Thanks for sharing, and looks like excellent work. What color(s) has owner selected/

Paul in CT |

|

|

|

|

|

#15 |

|

Senior Member

Join Date: May 2010

Location: Mpls, MN

Posts: 27,582

|

Not a bad days's work!!!

Really looks great and so nice to see another Model A come back to life as an original. Man, am I glad my 3 Model A's don't need patch panels!  Just curious, about how many hours to do this much work? |

|

|

|

|

|

#16 |

|

Senior Member

Join Date: May 2010

Posts: 1,643

|

Keep the updates coming. I think this is the first build thread I've ever seen on this forum, whereas on the HAMB there are litterly hundreds of them. Keep up the good work and as I said, keep the updates coming!!

|

|

|

|

|

|

#17 |

|

Member

Join Date: May 2010

Location: cape cod ma

Posts: 48

|

It is nice to see a young guy like yourself really take hold of this kind of work and do such a great job. Your intense conscientious attitude and great interest makes this happen and you are to be highly commended. BUT, take it kindly from and older guy with three sons much older than you, be more discreet in the language you use. You don't need to impress anybody that way. Your fine work speaks volumes for you in a much more positive way. Keep up the great work and think twice about using those loose words, they will only detract from your acceptance by others and results in people looking upon you as a person of lesser class. You show exceptional talent and deserve to be highly respected for it. Good luck to you from an old body shop guy.

|

|

|

|

|

|

#18 | |

|

Senior Member

Join Date: May 2010

Location: Eastern Tennessee

Posts: 11,509

|

Quote:

Well said Loumo. |

|

|

|

|

|

|

#19 |

|

Member

Join Date: May 2010

Location: cape cod ma

Posts: 48

|

Thanks Brent. We need to encourage this kind of talent and interest which truly comes from the love of this kind of work. And what I see of your work Brent, you are a fine example of this. Keep it up.

|

|

|

|

|

|

#20 |

|

Senior Member

Join Date: May 2010

Location: Innisfil, Ontario Canada

Posts: 1,174

|

Some nice work Brent. Looks like the Coupe had all of the regular weak areas. The Tig does a nice job. I've got to learn to Tig. Only a Oxy-acetylene and Mig guy. Nice to see some metal finishing as well. Keep up the good work.

Here`s some picture of a 30 I`m working on that someone had brazed in sections of the Upper Quarter panel sections. The Old Tinbasher. John Poole |

|

|

|

|

|

#21 |

|

Senior Member

Join Date: May 2010

Location: Savannah, GA

Posts: 1,300

|

Ready to try fiberglass instead?

__________________

20 years ago we had Johnny Cash, Steve Jobs, and Bob Hope. Now we have no Cash, no Jobs, and no Hope...please don't let Kevin Bacon die! |

|

|

|

|

|

#22 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

thanks for the criticism i appreciate it guys .changed some things to be more well spoken.

Brent i dont know if i would try to make the wheel wells myself . im sure if the customer was picky enough i would be .i would not know how to make a bead that big and the way the panel bends in at the front. this project is strictly time. thanks ray Kevin .I did the whole wheel well because 1 .the subframe was trashed . thats the main reason. def less work puttin the new piece in then all of the hammer and dolly work to straighten the orig piece plus the metal was torn and thin around all the fender studs. wheel well install was about 5 hours to what ya see now. 1931. He mentioned a 2 tone light brown dark brown. Tom .right now ill be in around 26 hours after i weld the passenger side wheel well in. thinking a hair over 35 to finish everything up that needs addressed . Loumo .i appreciate the feedback!! Tinbasher. ive never used the torch to weld but man is a tig amazing !i dont think i will ever use a mig on sheetmetal again if i can help it at this point. more pics when i get some more work done.thanks alot guys!

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 12-17-2010 at 06:06 PM. |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#23 |

|

Senior Member

Join Date: May 2010

Location: Mpls, MN

Posts: 27,582

|

I'm not a bodyman, but sure would have guessed a lot more time than you said to do that amount of work. Nice goin'

|

|

|

|

|

|

#24 |

|

Senior Member

Join Date: May 2010

Location: PASADENA, CA

Posts: 1,884

|

VERY NICE!!!!

That is a lot of very nice work for only having 26 hours in it. I do not know what your hourly rate is but I think the owner is getting a very good deal. Most "Body Shops" do not know how to metal finish. They will just weld in pieces with a MIG and Bondo everything and call it good. It is good to see this quality of work. Chris |

|

|

|

|

|

#25 | |

|

Member

Join Date: May 2010

Location: Toronto, Ontario

Posts: 63

|

Quote:

John, You are a bit too modest in your postings and I'm sure some others would like to see some examples of the quality work you do on your web site. http://www.tinbasher.com/order.html I've seen a couple of your son's race cars and they are show quality. |

|

|

|

|

|

|

#26 |

|

Senior Member

Join Date: May 2010

Location: Dayton, Ohio

Posts: 182

|

Sponsored Links (Register now to hide all advertisements)

|

|

|

|

|

|

#27 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

heres what i did today

the wheel well is in and it fought every minute of it for some reason .oil cans here oil cans there what a pain but it came out nice in the end.   tomorrows mission pick up some 18 gauge and make the lower quarter patches and body lines!!

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 09-08-2011 at 07:54 AM. |

|

|

|

|

|

#28 |

|

Senior Member

Join Date: May 2010

Location: Stayton, Oregon

Posts: 3,806

|

Very nice work. Keep it up.

__________________

Fred Kroon 1929 Std Coupe 1929 Huckster |

|

|

|

|

|

#29 |

|

Senior Member

Join Date: May 2010

Location: Spruce Pine, NC

Posts: 1,458

|

Flop, you're an artist. it does my heart good to see that someone with both skill & pride in workmanship will be around to take care of these cars after I'm gone. keep us informed of the progress on this one!

|

|

|

|

|

|

#30 |

|

Senior Member

Join Date: May 2010

Location: Creston Canada BC

Posts: 609

|

This guy is a artist , I wish to have his skill,

|

|

|

|

|

|

#31 |

|

Senior Member

Join Date: May 2010

Location: South California

Posts: 6,188

|

Flop,

Wow! Thanks for sharing. Where did you get such knowledge of metal forming at such young age? Rick |

|

|

|

|

|

#32 |

|

Junior Member

Join Date: May 2010

Location: El Paso Texas

Posts: 17

|

Nice work Mr. Flop.

|

|

|

|

|

|

#33 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

thanks fred

appreciate it chris and gerard! hardtime it kinda came naturally. started messing with cars when i was 15 and got a 55 caddy that needed a ton . rust ,mechanical the whole deal. now ive been through 10 or 15 cars and it just progressed into what ya see .it takes time alot of patience and a sharp eye. I strive to do work like guys like bass kustom and steve sellers those guys are always rasing the bar !! thanks michelle heres what i got done today since noone can make a quarter patch that looks right  more info when i finish it completely

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#34 |

|

Senior Member

Join Date: Sep 2010

Location: South Coast NSW Australia

Posts: 2,596

|

Is that zincanneal or zincseal you are using?

These may be OZ names. Is it DQ (drawing quality) also? |

|

|

|

|

|

#35 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

pooch here its called galvanneal get it dirt cheap from the hvac supplier near by.

what do ya mean by drawing quailty?

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#36 |

|

Senior Member

Join Date: Sep 2010

Location: South Coast NSW Australia

Posts: 2,596

|

Yeh galvanneal sounds like same stuff as ours here.

DQ is annealed very soft. It is hard to get, most of the zincanneal is high tensile. Easy enough for swaging and straight runs, but almost impossible to contour/stretch/shrink shapes into it. |

|

|

|

|

|

#37 |

|

Senior Member

Join Date: May 2010

Location: Seattle

Posts: 389

|

Flop, would you mind post pictures of the tools you used to shape the body lines?

thanks

__________________

Matt in Seattle |

|

|

|

|

|

#38 |

|

Senior Member

|

you sir are truly a artist and work fast!why couldnt i ever find someone such as yourself when i needed something fabricated. keep up the good work !!!

|

|

|

|

|

|

#39 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

thanks guys

ive never had any problems with galvaneal pooch . stock .mine.repop panel  alllll taacked in finally!!!   also tiged up some stress cracks behind the bracket that holds the support rod to the rad

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 09-08-2011 at 07:57 AM. |

|

|

|

|

|

#40 |

|

Senior Member

Join Date: May 2010

Location: Windy City

Posts: 2,919

|

Super build thread! Nice to see (and show) not everybody needs a 55 gallon drum of Bondo. The language tends to stay bible-belt clean here, unlike the H.A.M.B., but don't let that get ya down, I didn't really notice it until commented on. I'd like to be a fly on the wall and listen to the language patrol when the proverbial body hammer/ dolly finger pinch occurs.

My wife keeps a cuss-pot and occasionally uses the money to buy me repro parts. She figures a 2:1 return on investment. My wife keeps a cuss-pot and occasionally uses the money to buy me repro parts. She figures a 2:1 return on investment.

|

|

|

|

|

|

#41 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

thanks mike!

yeah i can tell the language part now WOW!!! i agree i would like to hear with the hammer dolly finger pinch or a busted knuckle when the wrench slips. but this is what ya get to do on xmas eve when you g/f doesnt tell ya shes going home for xmas  ill finish it up tomorrow. Merry Christmas guys!!!

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#42 |

|

Senior Member

Join Date: May 2010

Location: Mill Creek WA.

Posts: 341

|

HELLO Flop, Just keep the Great work up and just try to balance work and pleasure. It works every time. MERRY CHRISTMAS AND HAPPY A NEW YEAR. Don

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#43 |

|

Senior Member

Join Date: May 2010

Location: Paris, Tennessee

Posts: 182

|

Flop, very nice work. Thanks for taking the time to document your progress and post it here. The bad thing is you have probably cost me some more money. I've been on the fence about buying a stud gun for a long time and now I think I'm gonna pull the trigger after seeing your body work.

Tell us more about the tools you are using if you have the time. Thanks!! |

|

|

|

|

|

#44 |

|

Senior Member

Join Date: May 2010

Location: Eastern Tennessee

Posts: 11,509

|

I can save you some money my2nd40 and tell you that we don't own a stud gun and in almost 15 years of professional restoration on all the cars we have done, I have yet to see a need for us to own/use one. Allow me to explain...

A dent is nothing more than metal that has been stretched due to trauma. The correct way to repair the dent is to reverse the stretch in the same basic order in which the trauma was inflicted. Using a stud gun to attach a nail-sized stud to the metal and then jerked does not shrink the stretched metal but instead just restretches the metal in a concentrated area and thus only re-arranges the shape of the metal. To correctly repair a dent, the metal needs to be shrunk. Study the options and become proficient at one and you will likely find just a few small hand tools are all that is needed. Now if you still feel the need to spot-weld a nail, consider taking a couple of small flatwashers and touch the edge to a grinder to create a flatspot. Now, this washer can be tack-welded to a panel. Next use a pair of Vise-Grip locking pliers to apply some pressure as you use a slapper or dolly to raise the dent. . |

|

|

|

|

|

#45 |

|

Senior Member

Join Date: Oct 2010

Location: Bothell Washington

Posts: 530

|

Thank you, this is a fantastic thread!

|

|

|

|

|

|

#46 |

|

Senior Member

Join Date: May 2010

Location: Paris, Tennessee

Posts: 182

|

Sponsored Links (Register now to hide all advertisements)

|

|

|

|

|

|

#47 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

I have to disagree Brent. Ya get some heat from the stud gun and ya get a shrink from that mixed with the pull from the stud.Even when ya weld something on you still gonna get distortion from the weld. stud gun was by far one of the best purchases ive had. doubled panels braces in the way etc . priceless. plus if you take the time to tack weld a washer on your def gonna damage that panel trying to get it off with a grinder. the stud gun really helps taking the under cut right against your weld ever wih a panel that you have full access to the back.

gotta do the front edge over since i couldnt make a nice break because of the bottom bead.tomorrows mission thanks again guys!

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 09-08-2011 at 07:58 AM. |

|

|

|

|

|

#48 |

|

Senior Member

Join Date: May 2010

Location: Crown Point, NY and Punta Gorda, FL.

Posts: 259

|

Nice work Flop, I'd like to be a fly on your shop wall to watch and Learn your Procedures. I agree with you on the use of the stud gun, I have watched a local body man, use his, then hammers and dollies, when he finishes, hardly any body filler.

I hope you have Front or Rear fenders to fix, or Running Boards Many of us have them with Cracked and Split Front edges, along with holes. Some I have need lower sheet metal replaced, where The fender meets The running board. Most of us don't find good ones, or have the $$ to buy Metal Repos. Keep the Photos coming, good Job, you are a "Master at what You Do". |

|

|

|

|

|

#49 |

|

Member

Join Date: May 2010

Location: South Texas

Posts: 97

|

Nice work Flop! What did you do the second day?

__________________

"Rules are for the guidance of wise men and the obedience of fools." |

|

|

|

|

|

#50 | |

|

Senior Member

Join Date: May 2010

Location: Eastern Tennessee

Posts: 11,509

|

Quote:

Well, if you say so. Maybe I should come up and get some sheetmetal lessons from you!!  . |

|

|

|

|

|

|

#51 |

|

Senior Member

Join Date: May 2010

Location: Reseda, Calif.

Posts: 2,188

|

Flop. I agree with you on the stud gun. Have used mine a few times and if used right it is a very handy tool to have. Excellent work your doing by the way. Keep us updated.

|

|

|

|

|

|

#52 |

|

Senior Member

Join Date: May 2010

Location: Hannibal, Mo.

Posts: 124

|

Brent know this is going to sound like I'm taking sides...but I'm really not. Everybody has different ways of doing things...and I'm sure that the work you do is exellent. But don't try to blow someone elses candle out to make yours seem brighter. I don't know how old you are, but this young man is 25 yrs.old. I don't think you will find one person on this thread that would fault his work. I for one think the work he has shown us so far is top notch. If he can do the quality of work he is doing at 25 just think what he will be capable of at your age. All i'm saying is cut him some slack, he's definately not a butcher. All the best.

Stan/Mo. |

|

|

|

|

|

#53 |

|

Senior Member

Join Date: Sep 2010

Location: South Coast NSW Australia

Posts: 2,596

|

The only criticism I can hand you Flop is....

I wish you would use a sandblaster to clean the metal, where there are no repairs to be done. I cringe at the 36 grit disc sanding of the wheel arch ridge. |

|

|

|

|

|

#54 |

|

Senior Member

Join Date: May 2010

Location: Fort Worth, Texas

Posts: 1,055

|

All i can say is WOW. You do amazing work. No matter what people tell you about you language, or that they would do it a different way than you did, you sure know your doing. Keep up the good work, and keep the pictures coming. One of the best threads ive seen on this website.

__________________

Cowtown A's |

|

|

|

|

|

#55 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

thanks jazz. nothing to exciting in the shop really weld hammer grind repeat.

fenders are coming to the shop soon. also have new repoped running boards. thanks ccw and zz stop by any time brent. appreciate it stan thanks pooch appreciate the critism. it was a pretty wore out piece on a 4500 rpm sander def wasnt going at it with a grinder those will sand right out with a piece of 60 or 80 thanks logan!! def gonna keep on keepin on!! heres todays work when i made the patch panel there was no way i could use the sheetmetal break to get a clean edge because of the body line at the bottom so i had to cut the edge off and replace it with a piece i made on the break.  tacked in  where a stud gun really come in handy. metal brace and wood in the way .

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 09-08-2011 at 07:59 AM. |

|

|

|

|

|

#56 |

|

Senior Member

Join Date: May 2010

Location: Seattle

Posts: 389

|

Looking good Flop. I wish I was closer so I could come and bug you.

__________________

Matt in Seattle |

|

|

|

|

|

#57 |

|

Senior Member

Join Date: May 2010

Location: Eastern Tennessee

Posts: 11,509

|

Ok Flop, I am not following you, how did the stud gun help you on that patch in the forward quarter panel? Also, how are you planishing your welds?

On the comment when you made the lower patch, in the jamb area wouldn't a pan break or a tipping wheel worked well in this instance to give you a clean line?? . |

|

|

|

|

|

#58 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

hey brent stud gun helped raise the under cut area next to the weld .you know what i mean? the crater ya get right next to em if ya grind and then do nothing else?as far as planishing brent i use the snap on shrinkin hammer but not the shrinking end i use the smooth face because it has the largest face.

yeah i dont have the $$ for a pan break yet. i used a hand sheetmetal break to make it before i put the panel in but it went from ok to worse fast once i put it in and started making it match the original a metal. my tipping die in on loan to my friend whos out of town for christmas!!!

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#59 |

|

Senior Member

Join Date: May 2010

Location: Eastern Tennessee

Posts: 11,509

|

Hey Flop (BTW, is that your real name??) I think what you are calling an "undercut" is the term I am struggling with and not understanding.

The general term for a weld that has not been planished is a proud weld. As you well know to eliminate this, the weld is made and then planished using a hammer or slapper and also using a dolly or spoon backup with the dolly-on method. This not only flattens the weld but it strengthens it and it normalizes the molecules where you do not have warpage. What I am trying to figure out is, ...are you saying the weld is warping the sheetmetal on the edges --or is the "undercut" something caused by the grinding? I'd bet you were ready to strangle your buddy when you needed those tipping dies and he had them locked up!!  They would have made quick work out of it. Have you ever used a crescent wrench to tip with when you need to do a curve? That might have worked well here and then used a shrinker to take care of the excess. They would have made quick work out of it. Have you ever used a crescent wrench to tip with when you need to do a curve? That might have worked well here and then used a shrinker to take care of the excess.. |

|

|

|

|

|

#60 |

|

Senior Member

Join Date: May 2010

Posts: 130

|

Flop, incredible work. I have a few questions. What size tungsten tip have you found that works best for this type tig welding? What type and size filler rod? I have been using .040 tip and .023 -6 mig wire, but I would be willing to try something else if it might make things better for me. Also, is it better to start the planishing while the weld is still hot/warm or do you wait for it to cool? I would love to read any tips you can post about metal work.

Keep up the impressive work and keep posting! |

|

|

|

|

|

#61 |

|

Senior Member

Join Date: Sep 2010

Location: South Coast NSW Australia

Posts: 2,596

|

Yo Flop, I have been in the sandblasting game for 35 years. so that is why I cringe at disc sanding panels.

That coupe paint looks pretty good. I take it you do not have a sandblaster and I figure your old sand paper is clogging with paint and causing heat before you get to metal, as well as the sand marks in panel.. Try a heat gun and a sharp putty knife to melt paint off. Then if you must, it will be a very light lick over with 120 grade. Get a 2 inch wide putty knife and cut it back to about 1 1/2 inches LONG and round the edges off, so it is short and very stiff. Heat the paint and you will know when it gets soft enough to peel off in sheets, way before any excess heat will warp panel. Start on an angle with knife under paint and blow heat forward and keep going. You would do that 1/4 panel in about 15 minutes. Thick paint is best for heat, not so good with thin paint. Some types of paint don't react too well to heat, then you must resort to stripper if you do not have a blaster. If I have to strip a panel smooth, no blast profile for paint tooth, I run over with an orbital sander with worn out 36 grit. Gives a perfect tooth for primer. Here is one of my old videos. I will make a better one next time I have to blast and get dirty. (apologies for work behind hand a bit, because I was holding cam with one hand while blasting and thinking the lens was getting peppered. I will cover the cam with plastic next time for a better view).

|

|

|

|

|

|

#62 |

|

Senior Member

Join Date: May 2010

Location: Eastern Tennessee

Posts: 11,509

|

Wow Pooch, ...maybe it was a good thing your hand WAS there to protect the camera lens from ricocheting media!! I DO agree with your assessment regarding stripping using a disc.

One thing in FLOP's defense regarding the paint stripping is when doing a customer project, often times the 'how', --or 'what' he wants to do it is not an option. There are things we do that might cause others to question why we did it that way when the true answer is either we did not have the budget to do it the proper way, ...or the customer did not want it done that way. 30cab, check for a PM. . |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#63 |

|

Senior Member

Join Date: Sep 2010

Location: South Coast NSW Australia

Posts: 2,596

|

Just to add, I did not use this plastic bottle blaster when I was doing it full time.

I sold all my industrial gear when I retired. The bottle is just an example of how to make a clog free suction/gravity fully adjustable set up. |

|

|

|

|

|

#64 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

just about finished up with the body today besides bending the edges over the subframe on the new patches.

the passenger quarter was the last piece. really solid but the break where it wrapped under neath was gone made a new piece for it   couldnt figure out how to make it in one long piece so 2 pieces it was  just about done except for the edge it still needs some more smoothing where it wraps into the wheel well  and we are just about done with the body!!

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#65 |

|

Senior Member

Join Date: May 2010

Location: Stayton, Oregon

Posts: 3,806

|

Flop, great job and looks like a brand new A body.

__________________

Fred Kroon 1929 Std Coupe 1929 Huckster |

|

|

|

|

|

#66 |

|

Member

Join Date: Sep 2010

Location: Campbell River BC Canada

Posts: 59

|

Sponsored Links (Register now to hide all advertisements)

|

|

|

|

|

|

#67 |

|

Junior Member

Join Date: May 2010

Location: Richmond, VA

Posts: 28

|

Awesome work as usual Flop. How's the Pontiac coming along? I noticed a few cameo shots in this thread.

__________________

Now taking donations of money, parts or both. Inquire via PM. |

|

|

|

|

|

#68 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

thanks again guys. not done yet still got some little stuff and fenders to fix

dash needs some extra holes filled thats the next small project .is the passenger side of the dash supposed to have the reveal in it .you can see it where the sanding marks are.if it not its a hell of a perfect creas put in some how .  heres a pic of what everyones been asking for. what tools i use to do this stuff. once again i have no compressor use a 4500 rpms sander and a 4 1/2 inch grinder with the rubber backer cut way down so ya get less grinder marks  Druss pontiac is being neglected havent touched it in months .

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 09-11-2011 at 07:59 PM. |

|

|

|

|

|

#69 |

|

Senior Member

Join Date: May 2010

Location: Torrington, CT

Posts: 609

|

Nice work Flop...

Keep us posted Bill |

|

|

|

|

|

#70 | |

|

Senior Member

Join Date: May 2010

Location: PASADENA, CA

Posts: 1,884

|

Quote:

It appears you are working on an early '30. These firewalls had a bad habit about cracking around the radiator rod mounts. Ford later made a revision and added reinforcements to the back side of the firewall to help keep this from happening. You may want to think about adding something to reinforce this area. I have a early '30 Tudor that had this same problem and did not want it to re-occure so I reinforced this area when I did the repair. Just a thought. Chris |

|

|

|

|

|

|

#71 | |

|

Senior Member

Join Date: May 2010

Location: Eastern Tennessee

Posts: 11,509

|

Quote:

Below is a few images showing the cracks drilled, vee-ed, and filled. The reinforcing plates are added to the back side and the 4 holes are plug welded and metalfinished smooth to look more like a spot weld. The firewall rivets are heated & bucked in with a 3X gun to entirely fill the firewall hole first, then it is ground nearly flat on the backside and then waffled. The reason it is done that way is so the shank of the rivet can be red hot during installation for maximum swelling. The waffle tool is designed to be used cold, so thus it is done in two stages. . |

|

|

|

|

|

|

#72 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

good tips guys

extra holes in the dash that gotta disappear

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 09-11-2011 at 07:59 PM. |

|

|

|

|

|

#73 |

|

Senior Member

Join Date: May 2010

Location: Stayton, Oregon

Posts: 3,806

|

Nice, what did you use for the plugs?

__________________

Fred Kroon 1929 Std Coupe 1929 Huckster |

|

|

|

|

|

#74 |

|

Senior Member

Join Date: May 2010

Location: ⓉⒺXⒶⓈ

Posts: 2,047

|

About to go through all the same exact repairs on the coupe. Wish I could just drop it off! I'll be referring to this post a whole lot!

__________________

-------------- Drive it like you know how to fix it! DMAFC / OILERS CC-MC |

|

|

|

|

|

#75 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

of course it went to the sandblaster on the snowiest day of the year

and this is what it looked like when it came back and headed back to its owner this is just in epoxy primer no body filler  here is a short video of the car on youtube as well https://www.youtube.com/watch?v=hXVHPi9836c

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 09-15-2011 at 07:30 AM. |

|

|

|

|

|

#76 |

|

Senior Member

Join Date: May 2010

Location: ⓉⒺXⒶⓈ

Posts: 2,047

|

Yup. That's real nice. How many hours do you have in repairs?

__________________

-------------- Drive it like you know how to fix it! DMAFC / OILERS CC-MC |

|

|

|

|

|

#77 | |

|

Senior Member

|

Quote:

I saw at USA Weld a shrinking tip for a stud gun. I don't know if it will fit your gun.

__________________

What's right about America is that although we have a mess of problems, we have great capacity - intellect and resources - to do some thing about them. - Henry Ford II |

|

|

|

|

|

|

#78 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

Jason I have between 40 and 50 hours into the car on the sheetmetal work.

Mike I have the shriknking tip it work well for a small shrink.

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#79 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

2 separate customers sets of fenders i will be posting up soon

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 09-15-2011 at 07:32 AM. |

|

|

|

|

|

#80 |

|

Senior Member

Join Date: May 2010

Location: new britain,ct 06052

Posts: 9,390

|

Love your work and finished products.

Paul in CT |

|

|

|

|

|

#81 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

started on all the stuff today

bobs hood some extra holes for some reason    other side  holes   doms fenders i didnt like the patch that was in there so i put a new one in     about 3 more inches to go  stay tuned for more progress!

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 09-15-2011 at 07:35 AM. |

|

|

|

|

|

#82 |

|

Senior Member

Join Date: May 2010

Location: ⓉⒺXⒶⓈ

Posts: 2,047

|

It might be his car. And he might be able to fix whatever happens to it if something does.

__________________

-------------- Drive it like you know how to fix it! DMAFC / OILERS CC-MC |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#83 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

thats my car. calm down. i would never do that to a customers car.

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#84 |

|

Senior Member

Join Date: Nov 2010

Location: Argentina

Posts: 710

|

Oh!! that's the good taste of something made by yourself, That´s have another value!!

|

|

|

|

|

|

#85 |

|

Senior Member

Join Date: May 2010

Location: Sarasota Florida

Posts: 604

|

You have a lot of talent for a 25 year old. I keep looking at all the pictures over and over hoping some of your talent will rub off on to me.:-) Love the work. thanks for posting

|

|

|

|

|

|

#86 |

|

Senior Member

Join Date: Mar 2011

Location: Riverview, Michigan

Posts: 127

|

Sponsored Links (Register now to hide all advertisements)

|

|

|

|

|

|

#87 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

thanks everyone glad yu guys are enjoying the work if ya have any questions feel free to ask

finished up the first set of fenders    can figure out why these holes were here   small patch   a small tear where the fender support goes  took out the reinforcement thing by drilling 2 spot welds. cleaned up the rust and hit it with weld thru primer   a tear on the edge of the fender    a new reinforcement bracket for the fender where it meets the running board again both hit with weld thru primer    one more full set to go!

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 09-15-2011 at 07:37 AM. |

|

|

|

|

|

#88 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

broken motor mount. guess 80 or so yeras of service took its toll.

these fenders looked killer until i went to start on filling the old taillight holes   ohhhh its so nice of you to plastic up both sides of the fender to hide some mess  a little hammer and dolly work to get thing baack to normal before cutting out the area with the holes.

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 10-01-2011 at 07:30 AM. |

|

|

|

|

|

#89 |

|

Senior Member

Join Date: Nov 2010

Location: Argentina

Posts: 710

|

Very nice welded seam

|

|

|

|

|

|

#90 |

|

Senior Member

Join Date: May 2010

Location: South East NJ

Posts: 3,398

|

You are doing nice work.

I have a couple of suggestions based on my experience. You really want to do all the front and rear fender repairs on the frame with the brackets set up. You can lock in deformities that will make fender installation almost impossible. I had to undo some beautiful bodywork on a pair of fenders I bought. They were done off the frame and would not fit at all!!! It appears you were putting in a flat piece of metal at the tail of the fender. The 30-31 fenders are a compound curve in that area. The metal should be formed first before welding in place. From looking at your welding, do not try a TIG welder unless you can afford to buy one. You are not far from putting in panels with little or no grinding- just some hammer on dolly planishing. You are likely to find a TIG welder to be a wonderful change. |

|

|

|

|

|

#91 |

|

Senior Member

Join Date: May 2010

Location: Fresno, Ca.

Posts: 3,636

|

Flop,

Nice work! What size tungsten an filler rod are you using? The front fender, plus other parts look hot/too much rod, for an easy clean-up. Dudley |

|

|

|

|

|

#92 |

|

Senior Member

Join Date: May 2010

Location: Takoma park md

Posts: 271

|

very inspiring you keep tackling the hard stuff and come up looking good! what is weld thru primer and where do you get it?

__________________

Rust and roll will never die |

|

|

|

|

|

#93 |

|

Senior Member

|

Fixing the rear motor mounts, now you're just showing off.

__________________

What's right about America is that although we have a mess of problems, we have great capacity - intellect and resources - to do some thing about them. - Henry Ford II |

|

|

|

|

|

#94 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

thanks guys.

dj the tungsten is 3/32nds filler is prob. double the size of a .023 piece of mig wire. i use alot of rod for sure. i like to make sure i get it over lapping the seam to act as a filler i dont know why just have the best results that way.as far i heat i am set on 70 amps and have never been into the pedal id say more then half way. thanks kevin . the front fender with the tear on the edge was was tacked in place on the car and the matched to a perfect unaltered a fender and both had the same curve in the front . rolling... weld thru primer is a primer you can weld through.i put it in areas like behind brackets that get spot welded etc. thanks mike

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#95 |

|

Senior Member

Join Date: May 2010

Location: PASADENA, CA

Posts: 1,884

|

VERY NICE WORK!!!!

Where were you when I was doing the sheetmetal on my car???? Chris |

|

|

|

|

|

#96 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

i would have to kno the date you were doing your sheetmetal chris!

finished up the rear fenders with the bad holes. i guess these were on a roadster because he said the whole in the top of the passenger side was for a step.      other fender 4 really reaaly bad condition front fenders with spare tires holes next and a set of splash pans.

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 05-07-2011 at 04:37 PM. |

|

|

|

|

|

#97 | |

|

Senior Member

Join Date: Jul 2010

Location: Oslo, Norway

Posts: 521

|

Quote:

Your posts are probably one of the most interesting there are on FordBarn !! Keep up the good work, and keep posting !! |

|

|

|

|

|

|

#98 |

|

Senior Member

Join Date: May 2010

Location: Lexington, NC

Posts: 695

|

I agree. They say a picture is worth a thousand words but along with your commentary to help understand what we are seeing is an added bonus!

|

|

|

|

|

|

#99 |

|

Senior Member

Join Date: May 2010

Location: Creston Canada BC

Posts: 609

|

Hi Gent's are there any stronger words then only " perfect job"... this guy is top.

Flop may thanks sharing this with us. Gerard |

|

|

|

|

|

#100 |

|

Senior Member

|

Don't you dare stop!!!

__________________

What's right about America is that although we have a mess of problems, we have great capacity - intellect and resources - to do some thing about them. - Henry Ford II |

|

|

|

|

|

#101 |

|

Senior Member

Join Date: May 2010

Location: Homestead, Fl

Posts: 351

|

I second all the above. I get upset when you take TOO long in between posts! With me doing a coupe I get extra pleasure seeing what you are doing.

|

|

|

|

|

|

#102 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

well these are a set of splash aprons that looked decent until i got em back from the blasters.sand blaster always finds all kinds of nice things for me to fix!

this was all lap tacked i guess you could call it.  i ran a grinder down the slit to make it a butt weld

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#103 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

heres a fender i did recently with the hole for the tire.

yeeeeah i dont even know what causes damage like that.        gettin there     rear brace where it meets the running board    new pan had to be put in since the old one has seen better days   45 spot welds later

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 10-01-2011 at 07:32 AM. |

|

|

|

|

|

#104 |

|

Senior Member

Join Date: Jul 2010

Location: Aiken, South Carolina

Posts: 695

|

This is one of the best posts I have seen in a long time. Having done all of this kind of work, I studied each picture carefully. Superb! It is great seeing these repairs done correctly. Tons of work, but it is done right when you are finished-no doubts, no bondo, no cheating. Just solid and beautiful. Well done! Keep showing us more.

|

|

|

|

|

|

#105 |

|

Senior Member

Join Date: May 2010

Location: So Cal

Posts: 8,749

|

How about putting some of this on YouTube so we can see how it's done.

Bob |

|

|

|

|

|

#106 |

|

Senior Member

Join Date: May 2010

Location: Maryland

Posts: 145

|

Sponsored Links (Register now to hide all advertisements)

|

|

|

|

|

|

#107 |

|

Senior Member

Join Date: Oct 2010

Posts: 837

|

Jeez my right hand is numb. But certainly worth it!

|

|

|

|

|

|

#108 |

|

Senior Member

Join Date: May 2010

Location: Pitt Meadows BC

Posts: 1,003

|

Flop I have a question. When showing shots of your sheet metal patches, it is evident that you work and finish weld one edge at a time. Subsequent shots show the original tack welds and the patch is finished one side. Can you educate me on this method?, as I have always tacked all around until the joint is complete, (keep the heat down by spacing the welds) then finished the grinding/filing until I am happy.

|

|

|

|

|

|

#109 |

|

Senior Member

Join Date: May 2010

Location: Takoma park md

Posts: 271

|

how do you avoid pin holes and the little weld edges that always seem to need to be filed down?

__________________

Rust and roll will never die |

|

|

|

|

|

#110 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

thanks greg!

Bob that would be an 8 hour long youtube video on this fender! thanks rancho.little too much info Milton hahaha Farrell this method works for me. but if ya think about the jumping around method on a panel that is 4 by 4 inches your are still gonna heat up the whole area anyway. i love working a panel from one side to the other.i can make the finished work keep going.hard to explain but sometimes you get the right amount of crown /warpage from the heat.this just works for me . i never seem to get pin wholes with a tig i get occasional pits though. i do a ton of hammer and dolly work on the weld and on the edge of the weld.

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#111 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

well heres another fender that was in nice shape but a hack job of removing the spash pan that was attatched

getting it together   clamped

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#112 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

justa little patch i put in in

this fender is a train wreck but he wants it fixed so fixed it will get     ill show the rest when its gets finished up !

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#113 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

mmmmm brass and double paneled...needless to say that got cut out

new holes getting lined up and welded in.measured from 3 different place on a very nice model a fender so it should be pretty close to the right spot  one high spot i see haha.ill take care of that tomorrow

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#114 |

|

Member

Join Date: Mar 2011

Location: Los Angeles

Posts: 45

|

this is good stuff. Nice work, I am gonna be doing a bunch of patch panels soon and this is really helpful.

|

|

|

|

|

|

#115 |

|

BANNED

Join Date: May 2010

Location: Walla Walla, Washington USA

Posts: 6,066

|

Very professional Flop...Thanks for sharing your wonderful talent with us here on Fordbarn!

Pluck |

|

|

|

|

|

#116 |

|

Senior Member

Join Date: May 2011

Location: Snohomish,Wa.

Posts: 139

|

Hi Flop, just sent you an E-mail to get a price quote for you to work your magic on my 1930 Model A 4dr sedan rear fenders....Your work is ausome.....Dave

|

|

|

|

|

|

#117 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

glad i could help ollin

thanks steve!! appreciate the kind words! hopefully we get to work together soon dave! heres the finishing touches to the fender finished up another fender this morning some more stellar work  patch i made .a little english wheel action on it   last weld on it     badly brazed in  had to put a new pan in it as well. the ends were really bad they had to be cut out of the fender  and thats where my camera died but here it is finished up.the customer said the fender was gonna be junk i said naaaah its fixable now he has a perfectly good usable fender!

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#118 |

|

BANNED

Join Date: May 2010

Location: Walla Walla, Washington USA

Posts: 6,066

|

FLOP...Awsome man!

That is a lost art that many of us do not know what to do! Simply Awsome! To bad you are on the East Coast! Pluck |

|

|

|

|

|

#119 | |

|

Senior Member

Join Date: Aug 2010

Location: Winchester VA

Posts: 154

|

Quote:

There's a line forming...  I just drove from Winchester VA to Pittsburgh yesterday to drop off my '29 rears to have Flop save them for me. After the all the paint and filler was taken out when blasted it became even more evident that it was not something I could handle. Maybe I'll see his progress on them here!!

__________________

No time to play my Gibson RB-250 anymore.. Maybe.. One day... |

|

|

|

|

|

|

#120 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

thanks again steve

yours are next miles! his fender is another fine specimen of fantastic work   mmm brass and screws!    the bead rod was broke as well   used my bead roller to make the step    next fix the mess and get the pan to fit  just used the break to make the bend and a little shrinker stretcher action to get the curve.  i have to use a paper template to make this i can never get it in one piece ...     only 4 more feet of welding to go haha

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#121 |

|

Junior Member

Join Date: Mar 2011

Posts: 13

|

Thanks Flop for posting. You ran through most of the parts I need to massage on my car. Nice work

Ken |

|

|

|

|

|

#122 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

thanks ken!

heres the fender above finished up

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#123 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

this set of rear fenders are for thebanjoman on here

it ended up being in the wrong spot .i think this was a pick up fender with ther holes drilled for a coupe         a litttle thin

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 07-19-2011 at 08:04 AM. |

|

|

|

|

|

#124 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

some work i am doing on a 30 roadster

heres the start! dug inot the driver side cowl today found a mix of cement and some red oxide filler of sorts  cut out the mess and found a solid area to work with  welded up the inner piece and seam sealed it up   i made the body line on the harbor freight bead roller with the step die and some work to give it crown . way easier to make your own in my opinion then mess with patch panels   finished up  this crack is really throwing the alignment of the door off on the bottom. its on the top rail you could say on the quarter panel  crack open  craack closed.makes the door fit waaaay tighter to the body  ground a bunch more useless red oxide out of the door now its loking like a nice solid start!

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 10-20-2011 at 07:06 AM. |

|

|

|

|

|

#125 |

|

Senior Member

Join Date: May 2010

Location: Mpls, MN

Posts: 27,582

|

Nice work! I'll bet I can find 3 houses for sale in the neighborhood if you, Marco, and Brent want to move in.

Then I wouldn't have to learn body work. Then I wouldn't have to learn body work.

|

|

|

|

|

|

#126 |

|

Senior Member

Join Date: Sep 2011

Location: canton,michigan

Posts: 312

|

Sponsored Links (Register now to hide all advertisements)

|

|

|

|

|

|

#127 | |

|

Senior Member

Join Date: Dec 2010

Location: Kritter Krick, Flaw-duh

Posts: 1,158

|

Quote:

Heck, I got a finished basement - carpet, TV, pool table, beds - all ready for 'em to move into - country life, pond full of fish in the backyard, and my wife's a great cook!  Seriously, Flop, for one of your "tender" years, you obviously have great talent - I'm 2-1/2 times your age and wouldn't have a clue where to start doing the stuff you do. BTW, just curious - any idea what those roadster cowl lights are from? Definitely not Model A. |

|

|

|

|

|

|

#128 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

i appreciate all the offer to move guys !!

thats why i put it up here jeep so maybe someone can learn from it. chud i looked at the lights for a long time today . on the lens it saw c.w. hall lamp company detroit michigan figured out why the door was hangin out at the bottom  all welded up   some filler. but i would much rather have some well used filler then rust  half finished ...the rest of the filler.    gonna have to pull the door to get around the hinges and pull the lock assembly to get around the handle hole  the next mess

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#129 |

|

Senior Member

Join Date: Sep 2011

Location: canton,michigan

Posts: 312

|

a question: what do you use to cut out those bad sections?

|

|

|

|

|

|

#130 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

norton cutting wheel on a 4 inch grinder.only wheel i have never had explode.

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#131 |

|

Senior Member

Join Date: Sep 2011

Location: canton,michigan

Posts: 312

|

Thanks-that's what I use, but I was wondering how you got those nice,straight lines. I guess I have to be more careful.

|

|

|

|

|

|

#132 |

|

Senior Member

Join Date: Jul 2010

Location: Aiken, South Carolina

Posts: 695

|

Hey Flop, keep up the great work and especially keep up the pictures and posting. Your pictures bring back great memories of my own endless hours of sheetmetal working-you're an inspiration, kind of makes me itch to get the ol sheetmetal work underway on something. If only I had the time......

|

|

|

|

|

|

#133 | |

|

Senior Member

Join Date: May 2010

Location: Connecticut

Posts: 220

|

Quote:

Rich

__________________

E30 68-B Cabriolet

|

|

|

|

|

|

|

#134 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

glad you are enjoying the posts greg!

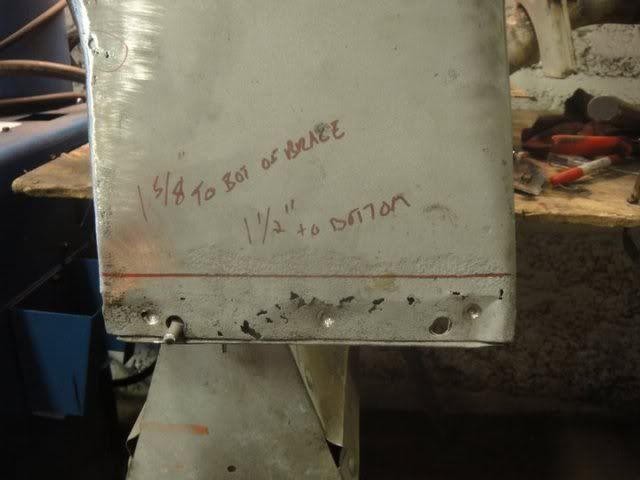

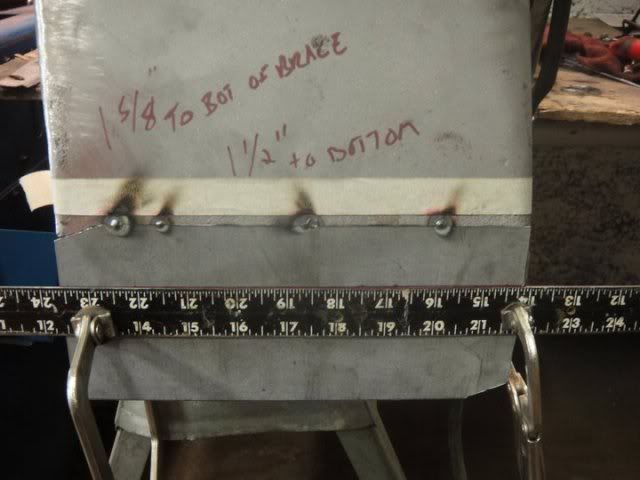

new subframe patch put it seam sealed ready for action haha  from the top  new patch tacked in

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#135 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

firewall business

a few extras   maybe the cleanest heater hole i have ever seen  goooone

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#136 |

|

Senior Member

Join Date: May 2010

Location: new britain,ct 06052

Posts: 9,390

|

AMAZING!!

Paul in CT |

|

|

|

|

|

#137 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

thanks paul!

onto the passenger side this side is way more solid in the subrail dept  some cement and red oxide type filler  sandblasted primed and seamsealed the few pin holes i welded up  begining of the patch  after the step   tacked in  finished up

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom Last edited by Flop; 10-25-2011 at 07:25 AM. |

|

|

|

|

|

#138 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

heres another project that came in . late 31 pick up cab with some severe bondo abuse and in a million piece

up to about a half an inch in some spots .   just a little bondo dust on the street . mostly stripped now gonna start on it in the spring have it ready for next june all back in one piece.

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#139 |

|

Senior Member

Join Date: May 2010

Posts: 111

|

Hey flop. Thats a good looking cab there hahahahhah. Can't wait to see it when you get done!

|

|

|

|

|

|

#140 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

hah thanks ian !

here are some 32 ford motor pans i did for jim on here just a bunch of cracks and brass nothing to exciting

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#141 |

|

Member

Join Date: May 2011

Location: Somerset, Ky

Posts: 66

|

Flop, Great thread and work. Where id you get subrail pieces? Care to share info? Great job!

Thanks |

|

|

|

|

|

#142 |

|

Senior Member

Join Date: Jul 2010

Location: Northwest Georgia

Posts: 178

|

Nice thread......it's good to see how patch panels are done step by step like this.....

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#143 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

29 roadster i made the sub rail pieces in shop

thanks leathernek!

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#144 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

heres a few rear fenders Rolland/Pittsburgh dropped off for me today

just a little bondo abuse ive seen much worse!!

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

|

#145 |

|

Member

Join Date: Jan 2011

Location: Central Maryland

Posts: 96

|

Flop, just discovered your thread. You do amazing work! I am fascinated by all the techniques you employ to tackle your various metal challenges since I have no clue about metal working. Along with many others, I really appreciate you taking the time to post on this forum and look forward to seeing more. When I need metal work done on my 31 Town Sedan, I know where I am going since I am only about 250 miles away! Keep up your great work!

|

|

|

|

|

|

#146 |

|

Senior Member

Join Date: Sep 2010

Posts: 492

|

Sponsored Links (Register now to hide all advertisements)

I just might make it to a stop near you soon now that I'm a solo act. I know I said that a couple years ago, but life in that shop was an hourly challenge. So far it doesn't appear as though you've had to, but some home brewed annealing can be handy at times. Get your sheet stock hot but not quite red, maybe a very slight red to it, let it slow cool for a bit, repeat 1 more time not as hot. That shi...uh...stuff (!) get's nice and flexy where you need it and makes complex curves easier to knock out. The shaping makes it hard again. Clearly you enjoy what you do. It shows. I just might make it to a stop near you soon now that I'm a solo act. I know I said that a couple years ago, but life in that shop was an hourly challenge. So far it doesn't appear as though you've had to, but some home brewed annealing can be handy at times. Get your sheet stock hot but not quite red, maybe a very slight red to it, let it slow cool for a bit, repeat 1 more time not as hot. That shi...uh...stuff (!) get's nice and flexy where you need it and makes complex curves easier to knock out. The shaping makes it hard again. Clearly you enjoy what you do. It shows.

|

|

|

|

|

|

#147 |

|

Senior Member

Join Date: Dec 2010

Location: pittsburgh pa

Posts: 576

|

thanks country squire!! glad you are enjoying the thread and hopefully learning somethings along the way !! hopefully we can get some work done on your sedan in the future!!

highlander!! thanks man .im enjoying it is right . not over worked i take only as much as i can handle .alot of planning involved to keep folks happy and projects flowing in and out on time plus having a small shop every square foot is critical! if you are ever in the pittsburgh area let me know ! the spot i though i was going to have to use the torch on today was loaded with plastic and brass so it got cut out and a patch was made. heres the before and after  while i was welding the patch in i had a bar clamped on the bead to keep everything in the position its supposed to be . i took it out for the picture

__________________

Please call or email while website is down! 412 867 1659 [email protected] https://www.facebook.com/flop.custom |

|

|

|

|

«

Previous Thread

|