|

|

#41 |

|

Senior Member

Join Date: Jun 2010

Location: Temecula, CA

Posts: 4,088

|

I recommend driving around the block without installing the cotter pins after initial tightening, then re-torquing and installing pins. I do this 2 or 3 times.

|

|

|

|

|

|

#42 |

|

Senior Member

Join Date: May 2010

Location: Mpls, MN

Posts: 27,582

|

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#43 | |

|

Senior Member

Join Date: May 2010

Location: Wa.

Posts: 5,408

|

Quote:

Read and understand the LAST paragraph in the above BobC's post #17. Bt lapping the hub to the axle and getting a 100% surface, you can run WITHOUT a key in a STOCK model A application. It is NOT a heavy duty application. HOWEVER, it is near to impossible to get 100% surface on an axle and hub with machined surfaces that has been run/abused, corroded and pitted. |

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 06:15 AM.

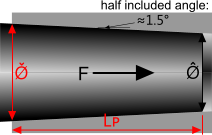

Fig 2. Self-Holding Tapers

Fig 2. Self-Holding Tapers Linear Mode

Linear Mode