|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

Thread Tools | Display Modes |

|

|

#21 | |

|

Senior Member

Join Date: May 2014

Location: Lafayette, La.

Posts: 100

|

Quote:

as far as cost, I do CNC machine repair for them and they do machine work for me (basically), so I would have to ask if they would like to reproduce the setup and how much. I can tell you they are not very busy. |

|

|

|

|

|

|

#22 | |

|

Senior Member

Join Date: May 2013

Location: Harrisonburg, VA

Posts: 841

|

Quote:

http://flatheadjack.com/119.html

__________________

The more I learn about new automobiles, the more I value my old ones. |

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#23 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,855

|

Well the 294 produced 235HP @4500 RPM (Red Line) This has a strap on the center main. I believe this belongs in the application area. Running allot of boost might change that. What surprised me was the 290 foot of torque at 3000 RPM, That's allot of torque. Makes you think???? Nice street engine.

|

|

|

|

|

|

#24 |

|

Senior Member

Join Date: May 2010

Location: Gardiner Me.

Posts: 4,200

|

My 286 in my dragster, I made a strap for center main 1/2in. steel, drilled and tapped a 3/8 threaded hole in the center and screwed a grade 8 bolt and lock nut and tightened it down. Run it 3 years, red line 5000 through the traps every run. Broke the drive shaft at the tree, checked the recall on the tach back in the pits, turned 7000 rpm before my boy got his foot off the peddle. Still runs like a clock, strikes every hour. lol Walt

|

|

|

|

|

|

#25 |

|

Senior Member

Join Date: Nov 2012

Location: Tauranga, New Zealand

Posts: 726

|

I am totally ignorant of the dynamics involved,and never been involved in any of this sort of development, but my immediate thought on looking at this was "why not a full girdle incorporating all three bearing caps, that lends itself to a flat bolt on sump surface.

|

|

|

|

|

|

#26 | |

|

Senior Member

Join Date: May 2010

Location: Wa.

Posts: 5,405

|

Sponsored Links (Register now to hide all advertisements)

Quote:

|

|

|

|

|

|

|

#27 |

|

Senior Member

Join Date: Nov 2012

Location: Tauranga, New Zealand

Posts: 726

|

I'm a learner. Thanks Pete.

|

|

|

|

|

|

#28 |

|

Senior Member

Join Date: Dec 2012

Location: Anchorage Alaska

Posts: 290

|

Bill, the side rails were not drilled and taped. I did that when I made the pan. It uses the original pan bolts are used to hold the sides down, but were brought up to 3/8 in the block. Then the sides were drill for the pan. Maybe Jim has pictures.

We did all the girdle stuff because I am hoping to make 12 pounds of boost with a 471. |

|

|

|

|

|

#29 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,855

|

The block is very thin along the rails

|

|

|

|

|

|

#30 | |

|

Senior Member

Join Date: May 2010

Location: Eagle River,Alaska

Posts: 352

|

Quote:

Last edited by outlaw; 01-11-2016 at 01:08 AM. |

|

|

|

|

|

|

#31 | |

|

Senior Member

Join Date: May 2010

Location: Eagle River,Alaska

Posts: 352

|

Quote:

|

|

|

|

|

|

|

#32 |

|

Senior Member

Join Date: May 2010

Location: ⓉⒺXⒶⓈ

Posts: 2,047

|

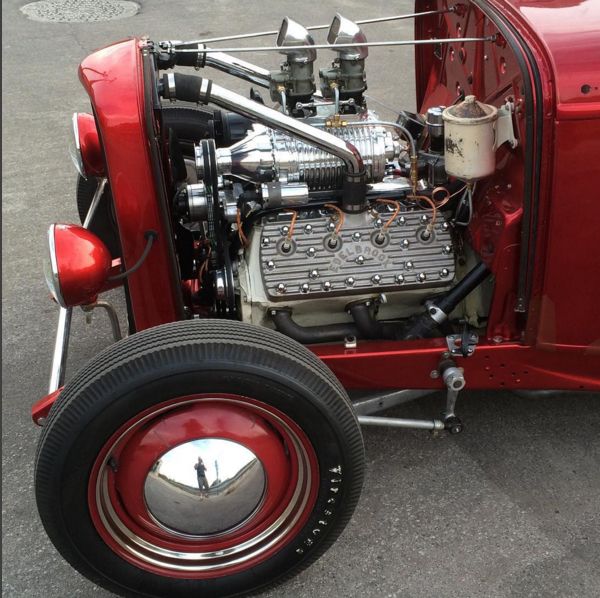

At The Race of Gentlemen, Brian Bass brought his 32 roadster with a mostly stock flathead. A week before the race, he obtained this new H&H Scot blower and decided to bolt it on before the race. It sure woke the engine up.

On about his 3rd race, I was in the other lane and near the end of the run, we could both hear a loud *POP* as if the car transmission popped out of second gear. However, he didn't remember it popping out of gear. He drove it back to the pits, idled the engine, revved it and heard no knocking or any unusual noises. He went back out on the track and raced 3 more times HARD and winning, and then drove the car back to his trailer about a mile away. When loading the car, he noticed dents in the oil pan. upon getting back to Dallas and dropping the pan, he found the main cap had sheered both main studs. Very lucky he didn't grenade the engine, but also an interesting occurance. Anyways, The supercharger can put enough force to blow the main cap!

__________________

-------------- Drive it like you know how to fix it! DMAFC / OILERS CC-MC |

|

|

|

|

|

#33 |

|

Senior Member

Join Date: Jan 2011

Location: Central Ohio

Posts: 5,062

|

I'd say that he is about as lucky as they come - can't imagine that the crank didn't let go! I'll bet his oil pressure had dropped off quite a bit?

I always replace the stock studs with ARPs. Maybe they help . . . maybe they don't, but in the grand scheme of things - not too expensive of an insurance plan (even for stock caps). |

|

|

|

|

|

#34 |

|

Senior Member

Join Date: May 2010

Posts: 886

|

Glad to see some info on blower engines, I have a set up from Mike Davidson Flatattack, it uses the billet caps and a re-enforcing plate, After seeing the broken bolts I am going to get the A.R.P studs, the kit has grade 5 bolts, I think the grade 5s will be a little too weak after going to all the expense to use this set up I cant imagine why one would use such soft bolts? They came with the kit. What is the deal about installing studs , I have heard a lot of people set and argue what is the correct way to install studs in an engine block ,some say tighten to torque spec. and some say don't tighten to spec. seems to me they will either be tight enough or not torqued and too loose and will come out. which is it?

fordestes |

|

|

|

|

|

#35 | |

|

Senior Member

Join Date: May 2010

Location: NJ

Posts: 6,177

|

Quote:

You said it. I can't believe the entire package didn't let go. That's pretty amazing. Tim |

|

|

|

|

|

|

#36 | |

|

Senior Member

Join Date: May 2010

Location: Wa.

Posts: 5,405

|

Quote:

|

|

|

|

|

|

|

#37 | |

|

Senior Member

Join Date: Apr 2015

Location: Sweden

Posts: 3,045

|

Quote:

Other wise when you tighten it up the loctite starts to move if you go over the holding point. |

|

|

|

|

|

|

#38 | |

|

Senior Member

Join Date: Dec 2012

Location: Anchorage Alaska

Posts: 290

|

I tighten studs in by hand. If its a take-a-part engine, then I usually lock tight them in. If you try to torque them in to a hole that is open, then you are forcing the shank of the stud into the threads. All you will do is screw up the threads.

Quote:

|

|

|

|

|

|

|

#39 | |

|

Senior Member

Join Date: May 2010

Location: Wa.

Posts: 5,405

|

Quote:

I didn't invent the idea. The guys that teach this stuff figured it out by math and then lab trials. I know a lot of people that build many different kinds of mechanical gizmos and they all do it this way. |

|

|

|

|

|

|

#40 |

|

Senior Member

Join Date: Apr 2015

Location: Sweden

Posts: 3,045

|

I installed large studs and it was very specific installed heights and we had spacers on and preloaded every bolt to specs.

And this was Loctites products and their techs teaching us. But perhaps it matters more when things are larger in diam. |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Thread Tools | |

| Display Modes | |

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 07:41 AM.

Linear Mode

Linear Mode