|

|

#21 |

|

Member Emeritus

Join Date: May 2010

Location: Madison, NJ

Posts: 5,230

|

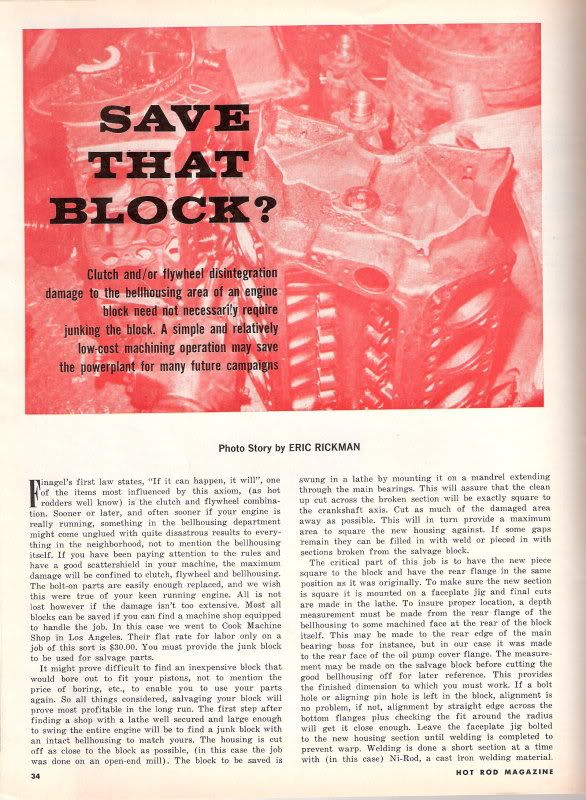

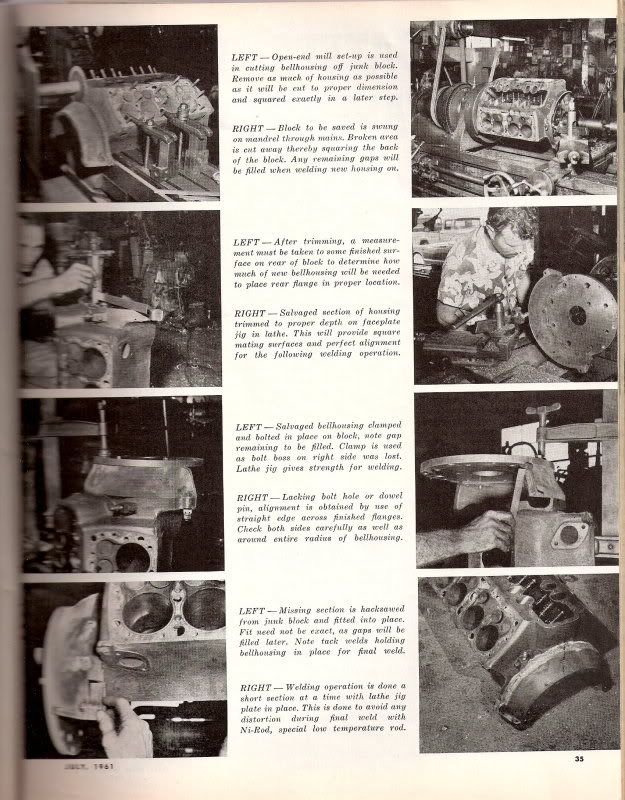

Hot Rod Magazine once printed a repair like this, I think around 1960. Their block was a real disaster, a racing flathead that had obliterated its bellhousing with a flywheel explosion!

|

|

|

|

|

|

#22 |

|

Senior Member

Join Date: May 2010

Posts: 2,871

|

Likely Ford figured you could change the clutch & throw out bearing by pulling the rear end.

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#23 |

|

Senior Member

Join Date: Jun 2012

Location: Clarkston, Michigan

Posts: 239

|

Thanks for posting I learned a lot.

|

|

|

|

|

|

#24 | |

|

Member

Join Date: May 2010

Location: Santa Rosa, California

Posts: 63

|

Quote:

This one's been given a rough trim with a small offset grinder . . .  . . . then finessed with a carbide burr in a die grinder and finished with a needle-scaler to give it an as-cast look. I soften and round off the ends of each of the needles on a belt sander to recreate the texture of the original surface.  More important on this thread, however, I've learned of some promising techniques for Ford block repair that we're likely to try in our shop. Thanks for that, folks. Mike |

|

|

|

|

|

|

#25 |

|

Senior Member

Join Date: May 2010

Location: Chester Vt

Posts: 8,855

|

I have a block in my shop that has both sides of an 8BA broken off and re welded. I wanted to post a picture, but my new computer doesn't have the program to do it. My grand son made it sseveral years ago for me because I'm computer challenged.

|

|

|

|

|

|

#26 | |

|

Senior Member

Join Date: May 2010

Location: Central Coast, Calif.

Posts: 839

|

Sponsored Links (Register now to hide all advertisements)

Quote:

I have a block that was most likely repaired by Cook's machine, as was shown in the article.   Neal |

|

|

|

|

|

|

#27 |

|

Member Emeritus

Join Date: May 2010

Location: Madison, NJ

Posts: 5,230

|

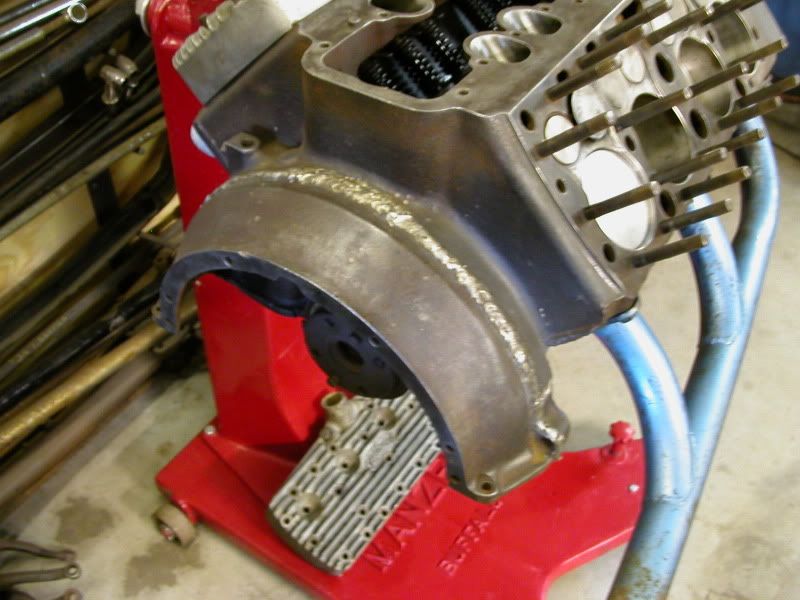

Museum of Modern Art grade welding!

|

|

|

|

|

|

#28 |

|

Senior Member

|

Here are some more shots before it was painted , I used A high nickel Ark rod to answer Marts question .We preheated with a LPG propane torch this was to take the chill of it ,we kept the heat going for some time after ,If you use a grinder you must be aware of grit intrusion .I intend this to be a budget build and I needed some pistons 60 over so got on the Internet ,I will use the Boring bar pictured to bore it , I intend to balance it my self so will post something on that later .

|

|

|

|

|

|

#29 |

|

BANNED

Join Date: May 2011

Posts: 409

|

You can't mention block welding without thinking of the 1937 60hp "tin" (stainless) side block. How'd they do that, it was a flawless machine weld. With my limited knowledge (closer to none than some) it had to be done in a heated environment and cooled slowly I would guess. Does anyone know exactly how it was done? I have never seen another example in industrial applications where that was done.

|

|

|

|

|

|

#30 |

|

Senior Member

Join Date: Jun 2010

Location: San Antonio, Texas

Posts: 16,420

|

I can only compare the way the pattern looks on the weld seam to the weld seam on the model A fuel tanks. I haven't seen the process for those either.

|

|

|

|

|

|

#31 |

|

Senior Member

|

good info here on cast iron welding, expansion & contraction video.

http://www.locknstitch.com/castironwelding.htm |

|

|

|

|

|

#32 |

|

Senior Member

Join Date: May 2010

Location: Taranaki, New Zealand

Posts: 922

|

When I was engineering we used to do a lot of cast iron welding, with brazing and electric welding rod, and we always preheated the article before we welded it by leaving it out in the sun for a start off sometimes, then heating it other ways. One instance was, we had a tractor come in with the back hydraulic mount smashed off, it was a large casting so we veed it out warmed it up and built up the broken parts with a Utectic cast iron electrodes we then welded it with the Phillips 56 electrodes and then filled in the large cavity with Phillips 28 electrodes. The owner of the tractor then carried on using the three point hydraulic system and had no trouble with it again.

Ted you have done the right procedure and made a good job of welding that V8 casting. |

|

|

|

|

|

#33 |

|

Member Emeritus

Join Date: May 2010

Location: Madison, NJ

Posts: 5,230

|

I read somewhere that the Model A tank weld (look at one...astounding, and they reached a production peak of nearly 2,000,000 in a year!) was done by "Mercury submerged arc" process...what that means I do not know!

The A was full of really neat automated welds...axle bells, banjo (the earliest banjos were fabricated from channel iron!), those gas tanks, etc. |

|

|

|

|

|

#34 |

|

Senior Member

|

Ian you have obviously been there ! Bruce as you say ,Our Fords are examples of very high teck welding .What's fascinating is how they did the rear quarter welding on the sedans it was some sort of fusion process ,The hot rod article is interesting .Thanks to all who posted

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Thread Tools | |

| Display Modes | |

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 10:08 PM.

Linear Mode

Linear Mode