|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

I have always been impressed by others on this site who let us into their world of all things Ford by posting their work in the form of words, diagrams, and photos. The craftsmanship and attention to detail is simply amazing. For the past several years, all that I have been able to do is work on sub-assemblies - carburetors, transmissions, engines, etc. Now I have delved into the realm where only the talented and dedicated dwell - an all out assault on your vehicle, by yourself, to do the mechanical, the body work, the paint, etc. At one time I had visions of grandeur on this scale when I put a 55 Sunliner project in the garage. The need for the family budget finally overwhelmed the whole idea, and alas - it was sold piece by piece. The sum total of its parts was definitely worth much more than its package value, but the old gal helped many a man complete his own Sunliner project in places around the globe. Well, all the while a 55 Fairlane sat idly by waiting her turn for attention. Some of you may remember that several years ago this car received a rebuilt 292 that really screamed even though an original Fordomatic was weighing her down and robbing her horsepower.

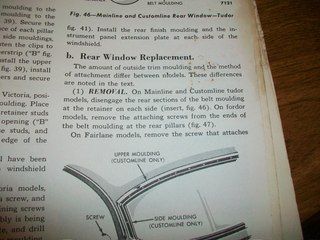

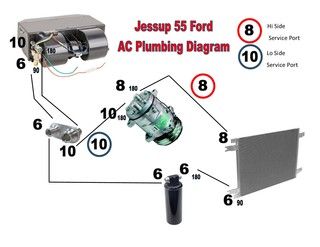

Here is the plan... to put her back on the road again with the following changes and facelifts: 1. Remove the 292 and check her out on the portable engine run stand. 2. Remove the original Fordomatic and lose it in the garage somewhere. 3. Prep and install an original 3 speed/overdrive manual transmission and all associated parts including the column shift. 4. Remove the worn out 55 steering gear and wheel so that I can prep and install a 1956 Steering gear, column, wheel, etc. 5. Remove the entire front end sheet metal to begin the prep for paint. The firewall will come first. Paint with the existing color scheme, SS Urethane red over white. (anyone ever use Summit's paints?) 6. Consider A/C to the mix - the wife is requesting it.  7. Finish the interior - the dash and sheet metal garnish are all painted and ready to back into the car. The headliner is 90% installed. Need to remove the rear glass first. That's enough for now. If you are wondering how I removed the hood by myself, first of all you can see the large blanket there on the cowl. I basically put that all the way across until it bunches up against the rear edge of the hood. Then I put the my engine hoist boom up against the front of the hood near the latch. I unscrew all 6 bolts where the hinges attach the hood to the car and then lower the boom up front. Voila! No scratches and the hood is free. I can then pick up the hood from the front, grabbing both sides and then set it aside. (don't worry, I will have help when I reinstall! Anyhow, this is what I accomplished this afternoon - the 292 has been removed and has been placed on a run stand. I am going to wire it all up, change the fluids, finish the accessory list, and hopefully fire it up tomorrow. You can see the starter hanging out loose in the Fordomatic. I just unbolted it and left it there before I removed the engine... why frustrate yourself?

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#2 |

|

Senior Member

Join Date: May 2010

Location: Phoenix,AZ

Posts: 1,417

|

You could pony up some bucks and get the adapter to replace the Ford-O-Matic with an AOD then you can retain your original shift column,but if you do decide to go stick shift let the members know you have an automatic column for sale there is a demand.

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#3 |

|

Senior Member

Join Date: May 2010

Location: Jackson N.J

Posts: 206

|

I will be following this Rev! IM doing a frame -off on a 56 victoria. Ive got pics in my profile on the H.A.M.B.Forum.

|

|

|

|

|

|

#4 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

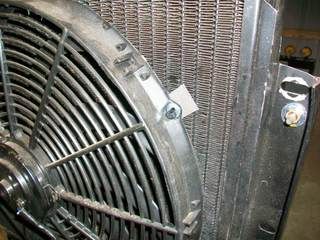

Thanks for the ideas fellas... Mike, I will have to look at your photos sometime later on tonight and "steal" your work lol.

Day 2 on the 55 is down, and I did not have much time today because of school supply shopping with the wife and taking her out to eat (tax free weekend in Virginia for school related items). We still have 3 kids in school. The oldest will graduate this year. Anyway, I did get the engine all buttoned up on the engine stand. In addition to installing those headers, the 54 radiator and electric fan, I also changed the oil and spun on a new filter. The run stand has an electric fan that I installed last year (operated by a toggle switch), a tray for the battery, its own gas tank, a gauge panel (I added a tachometer and a light for the ignition), and nice polyurethane wheels that I installed to replace the original casters that were too short to put the engine hoist under (go figure). The polyurethane wheels make this thing GLIDE across the concrete floor. The difference is amazing - those wheels make the load to push seem much, much lighter. The engine fired right up and sounded good, but I detected a miss - after checking all 8 spark plugs it looks like a few need to be replaced. Over the past 4 years, the engine has not been run that long, and when it has the engine never really got hot enough to burn off any deposits. The compression is still excellent. No leaks as of yet - well I take that back. The radiator cap needs to be replaced. The 54 radiator I installed has no overflow tube so the corrosion you see is the coolant leaking from there and then dribbling down the front of the radiator. I will take some time over the next few months to tune the engine and get it to where I like it for reinstallation.   Tonight on the front end of the 55 I began removing sheet metal. I removed the radiator valance, horns, brackets, hardware, etc, and starting organizing the items I removed. I looked again all over the engine bay and have come to the conclusion that I need to get a steam cleaner to do the best job I can. I remember using Steam Jenny's when I was a teenager and I just loved those things. They cut the grease and grime like butter. I called the only place in town that rented them - $300 a day. That's no typo - $300 a day. I called a place about an hour and a half away - $145 a day. Then, when I was out with my wife I got a lead on an acquaintance of mine that has a steam cleaner I could borrow. I have not called to confirm, but the mutual friends we have said it was so. I will find out early next week - won't a steam cleaner be a big help?!?    You can see in the second photo what I am doing to store all of the hardware. Instead of throwing everything into a large box, I am using those cheap $ store containers (4 for a buck) and then marking what the hardware goes to, which side, etc. I got in this habit when I rebuilt that 3 speed/overdrive unit this past Spring. I would think this will be a lifesaver (at least something to keep headaches at bay) later on when it is time for reassembly. I did have a snafu tonight - one loud "POP!" when I was at the rear of the shop. I had no idea what it was. I searched to see if something fell, something "sparked" (it almost sounded electrical), or what have you. But wouldn't you know it? When I picked up my air ratchet, I found the end had burst a hole. This air hose was one I got from china freight (harbor freight stores) several years back. It has worked well but I think the rubber is about to give way. I should probably use a whip hose. The hose that burst is attached to a retractable wheel - so I don't relish replacing it anytime soon.   I took some time to repair the hose before I left the shop tonight. How long this hose will last... I am not sure. I have a nice GOODYEAR hose but it is a larger diameter than this one. I definitely do want to use one of those PVC hoses on this unit. During the winter months it would be like unwinding solid cable! :P Tomorrow is the Lord's Day and I will be busy. Maybe I can get back in there tomorrow night after our evening services. On Monday, I am taking the day off to travel down to Felt's Machine Shop in Suffolk, Virginia. They have a crank and a set of heads for me.

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#5 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

mikhett... do you have a link?

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#6 |

|

Senior Member

Join Date: May 2010

Location: Granite City, Illinois

Posts: 3,008

|

Sponsored Links (Register now to hide all advertisements)

In the year 2000 I finished putting together my '55 Courier Sedan delivery. It was a struggle to get all the front end pieces aligned and levelled properly and I never really did get it right. I drove the car till 2010, then it sat in the garage collecting several inches of dust. About 3 weeks ago, I decided to tackle the alignment problems, finishing the job this very afternoon. Ive got it as good as it is ever gonna get, but at least now the hood closes properly and the gaps between hood, fenders and cowl are now all uniform for the first time. Needless to say I couldn't bring myself to re-assemble with the dirty, corroded fasteners, clips, brackets, etc, and wound up re-restoring many parts. I had to clean each threaded fastener, acid etch and apply sealer. For added protection, I am now in the process of covering each exposed fastener with duxseal. Probably the most helpful tactic I employed in the re-assembly project was the use of equal height of concrete blocks & peices of wood to hold up the front wall panels on each side of the radiator support. Once the proper height was established I was able to just slide the panels enough to be able to get the hood to close with even gaps all around. All front end fasteners must be assembled very loosely while tweeking the position of the panels. If there is too much friction, stuff won't move. Once you get everything positioned where it all fits right, tighten the front wall panels to the radiator support first, then snug down all the front splash pan to front wall bolts and the fender bolts and recheck the gaps. If needed, the splash pan has slotted holes to allow sliding to achieve the proper tilt at the very front of the front fenders to match with the angle of the front of the hood. |

|

|

|

|

|

#7 |

|

Senior Member

Join Date: May 2010

Location: Granite City, Illinois

Posts: 3,008

|

I used empty soap boxes appropriately labelled with magic marker to store all fasteners of common use during the project. It ended up taking up a table space 2ft square.

|

|

|

|

|

|

#8 |

|

Senior Member

Join Date: May 2010

Location: Granite City, Illinois

Posts: 3,008

|

PS; I'm keeping my Ford-O-Matic, FOREVER.

|

|

|

|

|

|

#9 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

On Monday I took the day off and went down to Suffolk, Virginia to visit Felt's Machine Shop. The place is a family owned and operated business that has been around for a long time. The owner, Jay Felts, knows Y blocks well. He told me his first car was a 53 Ford in which he took out the Flathead and installed a 312. Over the years, Felts has specialized in Ford engines. Anyhow, the visit down to Suffolk was to pick up a 312 crankshaft that had been ground down to 292 main size (we kept the slinger by turning the rear seal area in a lathe) and to pick up a set of ECZ-B heads they had reconditioned for me.

Behind the shop they had the best looking original 1935 Ford sedan I had ever seen in my life. The odometer read just a little over 11,000 miles and it showed. The story was that about 50 years ago this car was garaged and left to sit because Grandpa had passed away. Grandma did not want anyone driving it. She passed away 20 years ago and the family squabbled over the estate for some time until just recently when items such as this car were liquidated. The only issue with the car was that the Flathead had seized up because of the coolant corroding the interior of the block. Felt's resleeved a few cylinders I was told and they had just put the block back into the car. The condition of the car was amazing - check out that grille too.     The next stop was to see a friend of mine - Wayne Francis - who lived about an hour away from Felt's. I had rebuilt a Holley 4000 for him a month ago (thanks Ted for those O-rings!) and was going to make a delivery for him and look at what he had going on as far as projects were concerned. This was the 3rd teapot I had rebuilt for him. Wayne has a nice 56 Fairlane Town Sedan, a 56 Victoria project, and another 56 Fairlane Town Sedan project that he bought for $250 after someone had CHOPPED the entire top and left it that way. He is planning to make a roadster out of it since it is so rough. The doors had real problems staying put and the center support between the doors was very wobbly. (Big 6 ft 6 take note here.) Wayne plans to weld quite a bit of sheet metal in it and make it a 2 door, 2 seater, eliminating the rear seat.  It was a full day as the machine shop is about 5 hours away from where I live so most of the time was spent on the road. But it was worth it to see Wayne, to help him out, to get those parts back from Felt's (they know Y blocks pretty well and the prices are unbelievably low - so low that I would be embarrassed to post how little I paid to have a 312 crankshaft cleaned, magnafluxed, the mains turned to 292 STD, and the rod journals cleaned up at .010 - plus keep the rear slinger. I also had those heads cleaned, magnafluxed, surfaced, new seals installed, etc, for very little money. I do recommend Felt's if you live in that part of the woods. A deceased member of the forum was the one who led me to use them a few years back. I did not get much done, if anything at all, on the 55, but we had a good day foolin' around with Y blocks!

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#10 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

I drove my 55 when I was 16/17 years old with the Ford-O-Matic EVERY DAY back in the late 80's early 90's. The cast iron casing and the internals are near bullet proof that is for sure, but the rpm's are quite high on the Interstate and four lane highways around me. Going 65 mph (or more) was putting me at pretty high RPM... right around 3K or so.

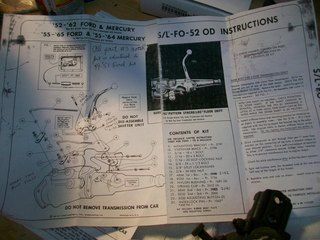

Installing Ford's 3 speed with overdrive unit will help out the RPM situation and bring down the revs at sustained highway speeds. Plus, I would get a weight bonus and I simply enjoy swapping gears with a "3 on the tree"! The Fordomatic will be kept in storage as will all linkage, etc. - I don't plan to scrap it, sell it, or get rid of it.

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#11 |

|

Senior Member

Join Date: Feb 2011

Location: SW WA state.

Posts: 564

|

I have to say that seeing the radiator grill sitting in the front seat of the 35 doesn't go over too well with me. What in the world were they thinking?

__________________

1956 Ford Fairlane Town Sedan 292 V8 with Ford-o-Matic |

|

|

|

|

|

#12 |

|

Senior Member

Join Date: May 2010

Location: Jackson N.J

Posts: 206

|

The H.A.M.B Member Mikhett go to profile.

|

|

|

|

|

|

#13 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

I guess I should have told you that the reason the gentleman brought the grill out was to show its pristine condition. It had been removed, cleaned, and then laid on cardboard on the front seat (there was cardboard on the seat back also). Not where I would have stored it, but the grill was so clean you could literally eat off of it.

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#14 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

thanks - will do!

UPDATE: Just got on there and looked at those photos - the color red you are using looks great on that dash! Can you do me a favor when you get time and show me a photo of the transmission linkage where it is hooked to the transmission and then where it is hooked to the end of the column? I have manuals that have blow ups of parts and their numbers and all, but no photos of what it looks like all put together. Nice pages!

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#15 |

|

Senior Member

Join Date: Feb 2011

Location: SW WA state.

Posts: 564

|

I dunno, if I were the owner of the car someone put the shell on the front seat, even on a piece of cardboard, I would be very upset. I also see in the photo that it looks like the shell is dangerously close to the steering wheel at the bottom. Those grille "teeth" look like they're almost chewing on the steering wheel.

I'm an owner of a low mileage Ford and things like this make me cringe. Other shops may have worked on my car before I owned it but no one else will ever work on it while I own it if I can help it.

__________________

1956 Ford Fairlane Town Sedan 292 V8 with Ford-o-Matic |

|

|

|

|

|

#16 | |

|

Senior Member

Join Date: May 2010

Location: Granite City, Illinois

Posts: 3,008

|

Quote:

Station wagons and Courier had 3.54:1 ratio, but those were integral housing type. T-Bird with Fordomatic had 3.31:1 ratio. |

|

|

|

|

|

|

#17 |

|

Senior Member

Join Date: May 2010

Location: westbury ny

Posts: 854

|

I to suffered from the harbor freight failure on the rollup unit I just replaced the 25 ft hose and we're back in business mine popped while I was priming a hood

|

|

|

|

|

|

#18 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

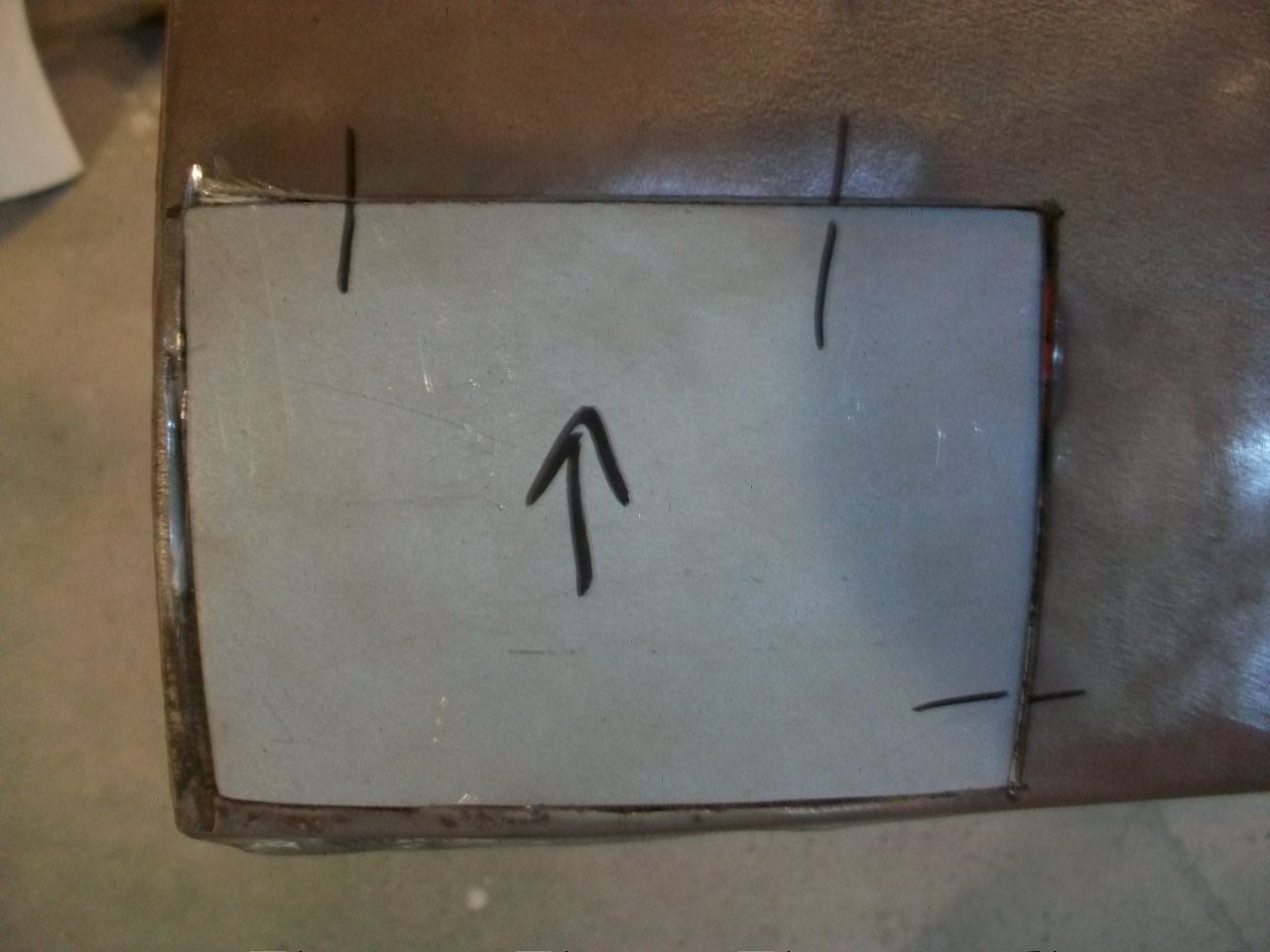

I am taking my time with the sheet metal removal and assessment, identifying and storing hardware and doo-dads as we go along. I figured there would be some rust out, but not in this particular area as I always believed this was the car's strong suit. I was surprised by the fender splash shield (I obviously broke off the tab) and inner fender strength and condition - not much rust at all and the parts are very, very solid. All of the bolts have backed out of their nuts and hardware fairly easily, with the exception of the one of the lower bolts near the rocker panel.

I am pretty sure that the front end sheet metal has never been off the car (but I don't know about that washer stack - read below), so the condition and minimal corrosion surprised me. The fender itself is very solid as you can see - especially around the splash shield area near the rocker panel. There is a bad spot about a foot above that - it will need attention. I think the other side has the same issue. I do not know what that is all about. You can also tell that the front lip inside the headlight housing is a little soft (the lip that attaches to the radiator deflector) - it may need some sheet metal welded in there too. So far the worst I have found is that driver's side air deflector, but the sheet metal to the left and right of the rot is very solid. I have already been banging on it with a hammer to find out how solid it is. I can cut that lip off and weld in some metal for a repair with out having to take out the whole thing, that way the measurements should be a lot easier to make and the fitment of new metal to the piece should go much easier. If this is all the rot I find, I would be very happy and count myself blessed. However I am expecting more! :angry: One last item - you see the stack of washers there on the firewall mount for the fender at the rear. What is all of that about? Is that something Ford did? I will have to check the manual - it seemed like a Mickey Mouse setup.

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#19 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

What hose did you buy to replace it? I definitely did not want to get another China Freight hose but I don't want the PVC stuff either - in the winter that stuff is like wood.

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#20 |

|

Senior Member

Join Date: May 2010

Location: Jackson N.J

Posts: 206

|

yours is a 3 speed on the tree with O/D right? Ill take pics whhen i get a chance Rev!That color is house of Kolor Cinder Red.Imtwo toning it with HOK bright white .i just finished the BW and paint on the deck lid.ill take pics of that too.

|

|

|

|

|

|

#21 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

Thanks Mikhett - the transmission I have rebuilt is indeed an original 56 Merc 3 speed with the R10 Overdrive tailhousing and attaching/actuating parts. I have all the parts (I think :>) to do the changeover from Fordomatic to 3 speed column shift - but I am planning to use a 56 steering gear/column ensemble here. What did you paint (or will you paint) your inner fenders/radiator air deflector/hood latch panel/etc? I was thinking of going with semi-gloss black Rustoleum. Painting the firewall the same color as the white exterior of the car.

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#22 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

[QUOTE=Might check to see if your car still has the original 3.23 to one ratio?[/QUOTE]

I will check on that sometime after I get the front end all apart and remove the Fordo, etc. I do have a 3.54 STATION WAGON rear end that I know is in good shape - I just pulled the cover 3 weeks ago to inspect it.

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#23 |

|

Senior Member

Join Date: May 2010

Location: Jackson N.J

Posts: 206

|

Southern polyurehanes black epoxy primer.A matte black it looks original and will keep rust at bay.I painted my frame on my 62 galaxie xl with it 8 yrs ago,its still holding up.

|

|

|

|

|

|

#24 |

|

Senior Member

Join Date: May 2010

Location: Granite City, Illinois

Posts: 3,008

|

The rust out at the air scoops on each of the two front wall panels is a common problem. The front wheels throw water, salt, mud and road grime up in that space and the stuff lays in there forever. It's too hard to get too when it is assembled to do a good clean out. About all you can do there is cut out the cancer and weld in new pieces of 18ga sheet metal with a mig welder.

I suggest painting the bare metal after welding with acid etch, then use a good rust inhibiting primer. As an overcoat, I used rust-Olem black. I recently had the front end all apart on my '55 Courier and discovered that the cheap rust-oleum paint had held up brilliantly through ten years of hard usage. Niether my '55 4-door sedan or my Courier had the washers on the ledge where the top of the fender sits, however, I wouldn't be opposed to using washers if needed to adjust the fender height to match the height of the mating surface of the cowl. There is supposed to be a strip of rubber between the fender and the cowl at that location. I noticed that your rubber grommet is missing where the left air cable penetrates the cown under that lip mentioned above. If you don't install that grommet, rain water will run thru that hole and flood the floor of the car. I believe it would have been much easier to remove your front bumper and splash pan first before trying to remove the front wall pieces. In addition, I noticed that you somehow removed the grille and left the park light housings in place. If you remove the 3 bolts at the back of each park light housing and then the 2 bolts at the center support, you can just lift the whole grille and park light housing out as an assembly (as long as the front bumper has been removed). |

|

|

|

|

|

#25 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

Back to the grind here... my parents came up to see my wife and I - and their grandyoungin's - and we had a great time together. I didn't get to work as much on the 55 as I had planned but spending time with mom and dad was well worth it. Besides, ol' Pops carried up a small pickup truck load of parts for me and I was pretty pleased with what I saw. It was from a Craigslist deal down in Pilot Mountain, North Carolina, and dad had agreed to bring up the whole lot for me up here to Frederick County, Virginia.

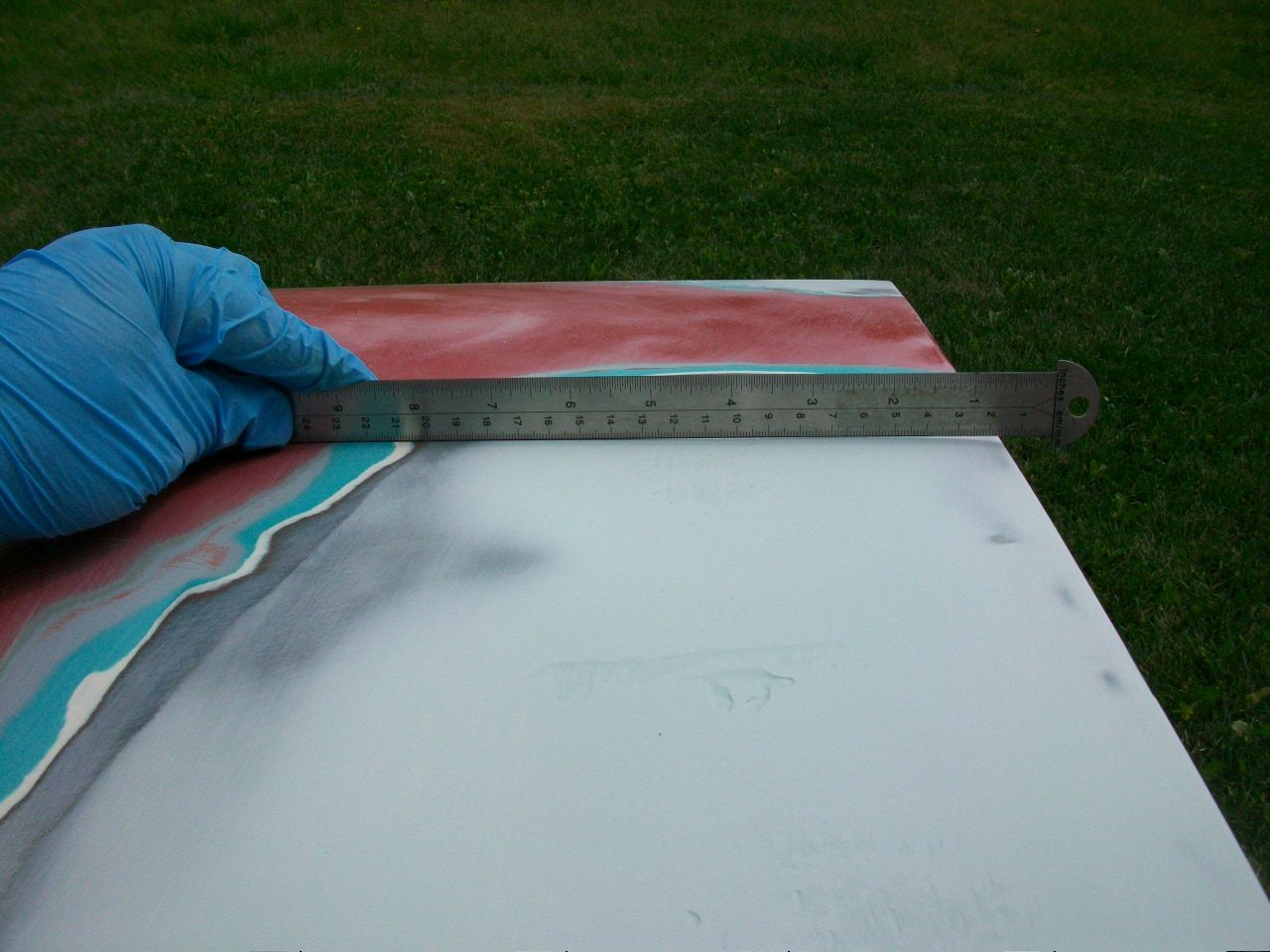

I did get the entire passenger side front end sheet metal removed. This time I had to simply remove some bolts by twisting them into two pieces but there were only two. The rest came out pretty easily. This passenger side air deflector is in excellent shape compared to the driver's side. Also, the fender lip underneath the headlight bucket is very nice. There are a couple of body work places on this fender, and I am thinking that I will have to completely remove the brace that runs the vertical length at the rear of the fender to get these repairs right, and then reinstall the brace before mounting. I had one hangup that was hard to to deal with at first - the hidden stud that goes through the body (behind the kickpanel under the dash) just spun and spun when I tried to take off the nut. There was no corrosion there so I couldn't figure out what the problem was. The stud just spun with the nut. I had to insert a long screwdriver and keep pressure under the washer as I tried to back out the nut. 5 minutes later we were ready to pull the fender and serious trouble averted. I have no idea how someone would get that fender off if that nut seized up. I don't really think you could get a grinder or cut off wheel in there. Anyone ever face that problem?       The parts were all degreased and I hit them with a pressure washer for a little while today. The splash pan is also in good condition and will clean up nicely. I will have to put some of these parts up in the rafters in the garage until I can get to things later on. The firewall and the frame is really what I want to attack first and get the car ready to place the transmission and engine back in there. There is definitely some body work to do. I am not going to be able to simply sand and paint, but I was expecting to have to work things over. It will be a learning experience for sure. I have had some questions about why I left the bumper on the front of the clip while removing everything else. It "should" be easier to remove the bumper after all the other parts are removed. I am expecting some very rough hardware on those bumper brackets and being able to get at them from the TOP with the sheet metal out of the way looks to be a good thing to do. A couple of questions: 1. What is involved in removing that brace that runs the vertical length of the fender? 2. Hardware - I have plans to degrease and blast the hardware per my ultrasonic cleaner and my glass bead cabinet. However, does anyone have some ideas on coating or finishing the hardware to keep it from rusting? I think the factory simply painted the heads of the bolts, but I am not going original here. If all of the hardware was one color that would not be a problem. This is a driver car for my father-in-law. 3. Thinking along the lines of hardware, has anyone made any updates to what Ford did to put all that sheet metal together back in 55? In other words, I am asking you guys that have disassembled and assembled front end sheet metal on 55/56 Fords with some frequency... was there any change you made to hardware use/location (fender washers, special fasteners, hidden nuts, welded hardware, etc)?

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#26 | |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

Sponsored Links (Register now to hide all advertisements)

Quote:

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

|

#27 | |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

Quote:

Say, you wouldn't happen to know of a place that sells that rubber seal (between the inner fender and the outer fender) in bulk would you? It looks as if someone could purchase a roll of it and then cut/staple as needed.

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

|

#28 |

|

Senior Member

Join Date: May 2010

Location: Granite City, Illinois

Posts: 3,008

|

At the back of the fender at the top, the fender attaches to the cowl with a 5/16" NF "flying saucer" fender bolt. There is a nut that is affixed to the underside of the lip by way of a couple of metal tabs. If there is sufficient resistance due to corroded threads in the bolt, those tabs can easily be destroyed and the nut will begin to turn freely with the bolt. You can finish the removal by getting a pair of vice-grips under there to hold the nut. Prior to re-assembly, spoit weld a new nut underneath that lip, centered in the hole.

At the bottom where the fender attaches to the underside of the rocker panel, the same type "flying saucer" fender bolt fastens to a nut that is affixed somehow inside the rocker panel. Again due to corrosion, that nut might break loose from it's mooring and just spin. I suspect many a '55 Ford enthusiast has burned off that bottom bolt with a torch to get the fender off. That nut can be attcked in a couple ways, either from the bottom or from the inner rocker panel at the front, requiring cutout and new piece of metal with the nut weled to the top of the metal and inserted into the cutout then welded in place. |

|

|

|

|

|

#29 |

|

Senior Member

Join Date: May 2010

Location: Granite City, Illinois

Posts: 3,008

|

Years ago, I was able to salvage the fender vertical brace where it was badly rusted away at the bottom by cutting out only the bad portion and duplicating it with 18ga sheet metal. It needs to be butt-welded (no overlap) and the mig welds must be ground smooth. If you don't do it that way, the fender might stick out too far at the bottom, and the bottom bolthole will not align.

|

|

|

|

|

|

#30 |

|

Senior Member

Join Date: May 2010

Location: Granite City, Illinois

Posts: 3,008

|

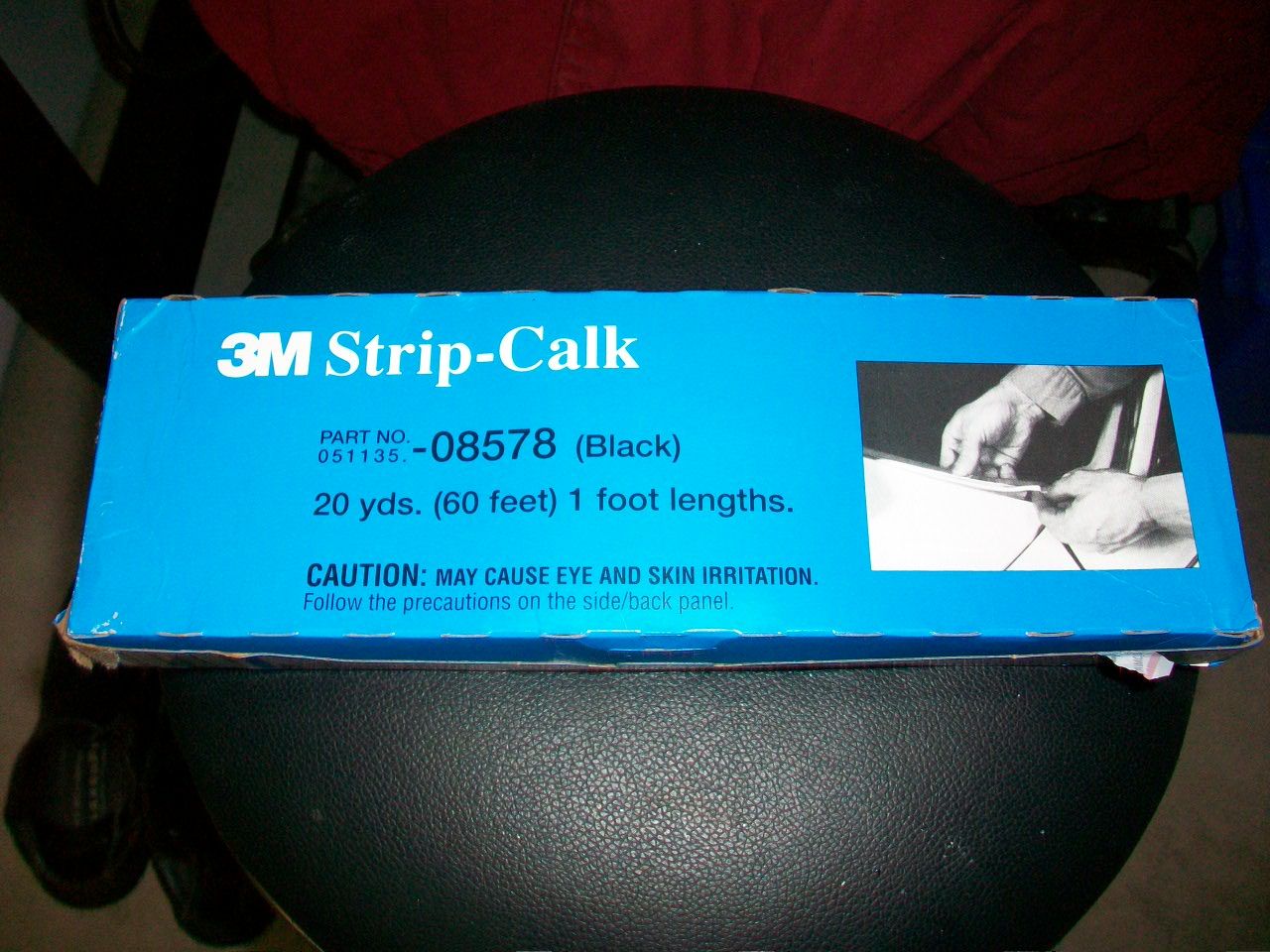

If you are referring to the seal that goes in between the inner fender well and the part of the fender at the top that bends down and mates with it, that is not rubber. I believe they used to call it permagum. It is sold at your local hardware store in a roll. It is made by 3M company. They don't call it permagum, though. I don't know what they call it. It is a soft, pliable material that can be bent, shaped and smashed with your fingers. Using that stuff for your seal would be as close as you can get to what the factory used.

|

|

|

|

|

|

#31 |

|

Senior Member

Join Date: May 2010

Location: Granite City, Illinois

Posts: 3,008

|

All your rubber seals for the inner fender apron are sometimes sold in a kit from places like Concours Parts, Dennis Carpenter, etc.. They include upper suspension arm rubber splash shields at the bottom, Rubber seal along bottom to frame and formed rubber strip that runs from the bottom of the tire splash shield all the way up to where the the fender apron meets the fender behind the magic-Aire duct. The seals are duplicate of original.

|

|

|

|

|

|

#32 |

|

Senior Member

Join Date: May 2010

Location: Granite City, Illinois

Posts: 3,008

|

I have tried several different ways to protect fasteners from corrosion after they have been thoroughly cleaned. Using a wire-wheel on a grinder motor is a great way to clean bolts. Sometimes a tap and die set must be employed to make sure threads are rust-free.

I tried re-plating with a zinc plating outfit. Re-plating provides the LEAST lasting protection compared to other things I have tried. I tried soaking in black oxide, heat and sealing the hardware. It's not guaranteed to last very long either. I tried spraying the hardware with a product called "Rust-Fix" (sold at most chain auto parts stores). Rust-Fix is similar to acid-etching unfortunately, you wear off some of the protection when using the fasteners. But it does seem to have some longevity. Lately, I have been using "Rust-fix" and for added protection, I have been covering the assembled fasteners with "duxseal". Duxseal is a product made to seal piping and refrigeration lines where they penetrate thru buildings. Duxseal is a moldable, pliable material like "silly Putty" except it is more dense. It does harden somewhat over time, but I have never had a problem removing a fastener that I had covered in duxseal. When my '55 Courier was finished in 2000, I had all nuts and bolts that were exposed to the weather covered in duxseal. That included all the splashpan to front wall nuts & bolts, parklight housing boltheads, grille center bracket nuts & bolts, above and below the splashpan and many other areas you'd expect contact with water, snow, salt, etc. Recently, when I had the Courier's front end all apart to perfect the alignment, every fastener that I had treated this way came out with no trouble, and 90 percent of the fasteners had no corrosion whatsoever. They looked like they did the day I installed them. The car had been driven in ever kind of weather immaginable up until 2010, so they withstood ten years of brutality. |

|

|

|

|

|

#33 |

|

Senior Member

Join Date: May 2010

Location: Granite City, Illinois

Posts: 3,008

|

At most major harware stores you can buy stainless steel hex bolts, nuts and washers of correct size and length to fit the front splashpan-to-front wall holes. You could use those also for grille and parklight housing mounting. They are the same size and thread. They don't look like the original saucer bolts and nuts though and will not be as good as the original serrated hardware for elecrical body grounding continuity, but you shouldnt need grounding continuity at the splashpan. You do need it for your parklights though unless you run a separate ground wire and fasten it with a serrated washer or a star washer.

|

|

|

|

|

|

#34 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

Things went really slow this week but when I look at these photos, I say to myself, "who cares?" My boy (I have 3 kids, 2 daughters and a son) came into the garage with me last night to work on one of his projects - he was making a homemade trailer to go behind one of his small Tonka type trucks. "Hey dad, can I help?" he says. "Sure thing," I tell him, and my 11 year old son Ethan (we call him EJ) grabs the air ratchet and asks what's next...

. I laughed a little and patted him on the back and we spent a couple of hours removing the front bumper, the hood hinges, various hoses and wiring, the sway bar, etc. It took me a whole lot longer because while he has his own hand tools he had never used an air ratchet before... I guess he has never really asked me to. Looking at the photos here I guess I should have made him wear a pair of safety goggles - will have to do that next time. He always knows to wear a pair when he is at the grinder or using a cut-off wheel or a Dremel tool. . I laughed a little and patted him on the back and we spent a couple of hours removing the front bumper, the hood hinges, various hoses and wiring, the sway bar, etc. It took me a whole lot longer because while he has his own hand tools he had never used an air ratchet before... I guess he has never really asked me to. Looking at the photos here I guess I should have made him wear a pair of safety goggles - will have to do that next time. He always knows to wear a pair when he is at the grinder or using a cut-off wheel or a Dremel tool.   I did take some photos of the front sway bar after removal and of a sway bar that I had on the shelf here. As I recall, it was from a 56 Station Wagon... can I mount that front sway bar with the same metal brackets? It looks like the bushings are the same but the ID of the hole is probably different. It looks like I will need new a kit for the hardware also. Those rubber washer bushings are WORE OUT lol. The bolts from the wagon sway bar look like they are a little longer. I guess there is such a thing as a kit for a wagon sway bar?      I will have to say that with my son's interest here this week things have gotten a whole lot more "fun". We'll see how long he lasts. The last thing he told me before we went in for a shower last night was whether or not he would be allowed to drive it when he got his license. I laughed and said, "You are going to have to talk to your Papa about that one!" I'm sure he will.

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#35 | |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

Quote:

I will check into the black oxide thing. I have heard pro's and cons on that one. I really don't want to have to purchase a whole new kit, but I really have not check into what that will cost.

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

|

#36 |

|

Senior Member

Join Date: May 2010

Location: Granite City, Illinois

Posts: 3,008

|

In noticed that the front anti-sway bar on my '55 car is a smaller diameter bar than the one in my '55 Courier Sedan delivery wagon. Apparently, the station wagons all have the heavier sway bar.

Yes you can get the new rubber bushings from most Ford resto suppliers. The u-shaped brackets are same for car and wagon. To my knowledge, the bracket bolts are same length on both my car and wagon. |

|

|

|

|

|

#37 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

Well I finally had a half day off today and got a chance to get in the garage for a few hours to turn some wrenches on this old Ford. Right now my life is very busy what with school starting up (I administrate or church's academy), the new volleyball season (yep - I coach girls' volleyball... don't ask me how I got talked into that but it has to do with my daughters lol), and everything else with a family of 5 I don't know how I have time. No complaints,,,, just letting you know the reason for so much time between posts.

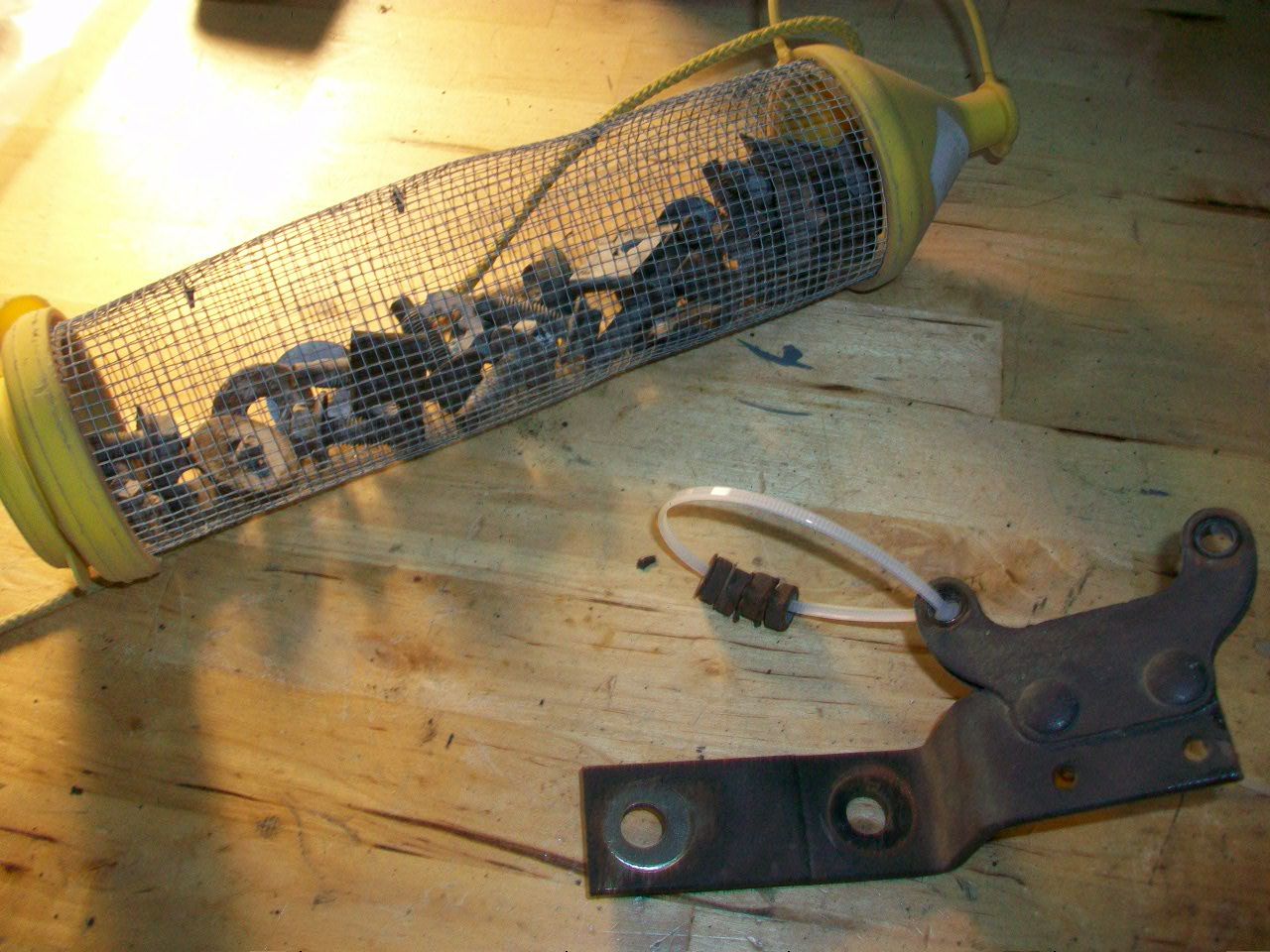

I removed the transmission and the crossmember along with the drive shaft. It took a little more time than I anticipated - stuff was really gunked up under there. I remember years ago that a rear main seal was dumping oil everywhere for while - guess it made the floor pans last a long time! I did find one small place on the driver's floor pan that was not solid. Everything else is good.         If you are wondering what is going on with the photo of the vise grips... I was looking around under there and found them clamped to a nut! I think the vise grips were left under there when the seat belts were installed. That's what I get for having teenagers help me turn wrenches! I should have counted all my tools after that project was done. I took them off... they are still good after 7 years or so and all the road time. That crossmember weighs an extra 5 lbs from all the crud, grease, and road grime collected on it. Gotta get that thing cleaned up and painted. I guess the transmission mount rubber is near perfect because of being sprayed with oil so much over the years. Hopefully I can get the firewall cleaned up soon and then start prepping the firewall for paint. I would like to do that before weather sets in here. The photos of the tail pipes are a for a member who asked for them sometime ago but I could not find his post. If you know the member or remember the post... can you direct him here? thanks

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#38 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

Alrighty back to work on the old Fairlane (after our first whirlwind week at school). I cleaned up the interior a bit and removed the dash and quite a bit of hardware. I already have a painted dash and painted trim pieces ready to install, just wanted to get all of this removed to make the firewall work easier. I also have plans to put in the clutch/brake pedal assembly that I have ready to go. On the list are quite a few grommets, a new wiring harness, and various pieces of anti-rattle/anti-squeak pieces. I am also going to replace the carpet.

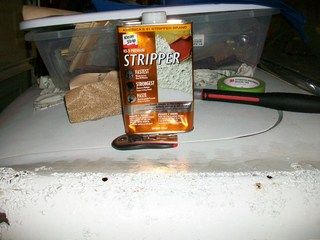

I also pressure washed the firewall and front end trying to degrease it... wasn't too successful there. I need a steam cleaner - anyone got one to loan out? :P After it dried I broke out the sandblaster but it did not work too well. The sandblaster is a decent one I got from Tractor Supply a few years back. Of course I was blasting in 90 degree weather and high humidity so that did not help, but my air getting to the tank was dry. I think the tank itself had some condensation in it working against me. I turned it over and put my flashlight through the hole to see the valve. On the interior of the tank at the bottom there were some "runs" of water leading to the valve. If you guys got any tips on sandblasting in hot weather I am all ears! I only got a little bit done on the firewall and had hoped to do a lot more today before being pulled off on another wifey project to make an antique headboard for my oldest daughter's bedroom. Maybe I will put up some photos of that project too. It is being made from a turn of the century door and vintage trim that is about 6" wide. She wants me to make "homemade" crown molding - haha, we will see how that turns out. I did order the Ford Wimbledon White for 66-69 Mustangs from Eastwood yesterday. Hopefully I can get this firewall painted (and maybe the hood hinges) before weather sets in.

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#39 |

|

Senior Member

Join Date: May 2010

Location: Granite City, Illinois

Posts: 3,008

|

If ya don't mind getting hands a little dirty, use a rag soaked in gasoline to wash off heavy grease from the surface and finish cleaning the entire thing with very hot water mixed with ample dose of dishwashing liquid.

|

|

|

|

|

|

#40 |

|

Member

Join Date: Dec 2011

Location: Seattle

Posts: 85

|

Do yourself a favor and put in a new upgraded swaybar. They are available in 1inch and 1 1/8 inch I think. I put a 1 inch on my 54( same chassis) and it made an amazing difference in body roll. There is a guy on here, Dave something, I think that sells a really nice kit. I'm sure he will comment.

John |

|

|

|

|

|

#41 |

|

Senior Member

Join Date: May 2010

Location: westbury ny

Posts: 854

|

if you do use gas please do it outside as it is not the safest but does work I find that simple green works well for tough dirt I use a scrub brush then pressure wash

|

|

|

|

|

|

#42 | |

|

Senior Member

Join Date: Jul 2011

Location: Redondo Beach, CA

Posts: 5,849

|

Quote:

I would use caution on using S/S hardware unless you assemble with an anti-sieze. S/S fasteners easily galls, the bolt and nut become one...

|

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#43 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

Not much done today on the '55... I completed a project that the wife and oldest daughter have been begging me to do - an antique headboard for my daughter's bed. The story goes like this... My parents moved out of an old home that was originally built in the 1850's, had been used as one of the hospitals for Stonewall Jackson's army, etc. In the scrap pile when they bought the place years ago and put stuff into storage was a very old door and 6" trim pieces as shown. When they sold the place and moved out they gave me the old door and trim pieces. "What do I want with these?" I said to them. My parents just smiled at me because they had gone behind my back and talked it up to my wife and oldest daughter about the idea of making a headboard out of this old door. Little did I know!

Anyhow since it was labor day I had some extra time to examine this thing and get the ball rolling to crank it out and get it done. You can google this idea for more photos on the internet - I am sure there are better ones than mine, but suffice to say I turned the door on its side, trimmed off both sides (what was the top and bottom), MADE CROWN MOLDING OUT OF THE OLD TRIM (please don't ask how that went lol - I finally worked it all out), and then put a piece of trim on the top for a shelf. My wife and daughter were thrilled to say the least and it all passed inspection. Best thing is the girls decided it did NOT need to be painted since the old patina was exactly what they were after.       Yep - that's me in the Ford tough shirt

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#44 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

duly noted on the gasoline scenario... not a big fan of doing that if I can help it. I have used Kerosene in the past too.

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#45 | |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

Quote:

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

|

#46 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

Sponsored Links (Register now to hide all advertisements)

I also had the chance to blast in the cabinet this past week so I got some of the frame pieces finished and linkage rods finished. I also sprayed the Tamco primer on the hood hinges. After doing so much dismantling it feels good to finally have something ready to go back into the car.  Question: I need to modify the split cover plate that goes around the column and screws to the firewall. My cover plate is obviously for a Fordomatic and not for a manual transmission car. Does anyone have good measurements on where that hole goes and its size? Does anyone have a split cover plate they would "part" with? EDIT: I got a good set of sheet metal pieces on the way! thanks to another ford barn member for the lead...

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! Last edited by Hot Rod Reverend; 09-30-2014 at 09:40 AM. |

|

|

|

|

|

#47 |

|

Senior Member

Join Date: May 2010

Location: Granite City, Illinois

Posts: 3,008

|

HRR! I believe I have all parts from the manual shift steering column on down to the manual 3-spd transmission, heck even including the course splined yoke for the driveshaft for a '55 with 6-cyl clutch & bellhousing. If I remember right, all the parts have been stripped to bare metal and have metal-prep applied. So yes the split floorplate for the steering column with the clutch pushrod hole is in with all that stuff, but I don't want to part with it unless I can get rid of the whole nine yards in one fell swoop. I will never use this stuff. I am a Ford-O-Matic man forever.

One of these days I've got to start running ads in the parts wanted section. |

|

|

|

|

|

#48 |

|

Senior Member

Join Date: May 2010

Location: Granite City, Illinois

Posts: 3,008

|

HRR!

I always had a fear of sandblasting partial subassemblies with some moving parts attached like that. I was told that sand gets in everywhere unless stuff you need to keep clear of the sand is well wrapped and tightly sealed from the blowing sand. Stuff like ball joints, brake drums, tie rod joints, etc, could incur major damage during normal operation if sand got in them. But don't take my word for it. Ask around and see if other folks of our ilk would have the same concern. |

|

|

|

|

|

#49 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

All of the front end pieces are being removed and replaced I am afraid. Quite a bit of work but the bushings are worn out, I am putting in new coil springs and shocks, etc. The steering gear is even being replaced/not rebuilt as I am opting for a 1956 steering gear and column.

Sand will tear up quite a bit of junk.

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#50 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

Spent a few hours today with the trusty sandblaster and the front end. I was surprised at how well my air compressor held up. I didn't blast continuously and would try to let the air compressor "catch up" from time to time, but I was happy with how it did and happy with the results. I also blasted a bellhousing - the pressure pot made QUICK work of that piece and the engine paint turned out nice. I only have about 5 to 6 hours on the pressure pot sandblaster I got from Tractor Supply a while back but I am not impressed with how quickly the "stopper"? is wearing out on the deadman's valve. The sand has worn away the tip on the closer (not just the ceramic tip - that is another story) but the top piece that slides over the tip - that piece is so wore out that the blaster now will leak air when the spring loaded lever is completely closed. I guess it is cheaply made. If there is anyone out there that has any good suggestions on a quality tip/closer I would appreciate it. I am going to look at TP tools. I have one of their Blast Cabinets and have used glass beads for 10 years now. I reckon I have spent countless hours using that gun and have only had to replace the nozzle about 3 times. I know sand is more abrasive, but come on... 6 hours???? :ermm: Maybe I should take some close up shots of the tip just to show the erosion that has happened pretty quickly.

Next up - disassemble the front end so that I can paint the frame and separately blast the pieces in the cabinet. I have new rubber for up front and I have new Aerostar coils as well. I did locate a split sheet metal surround for the steering column and shifter column, and I have started preparing the 56 column and other shifter parts for painting. I also have those hood hinges about ready for topcoat. If you have been wondering where some of the time goes for projects like these and why it has been a while since my last post, at times my wife gets me side-tracked on things like this.  She found this door today at an Apple Harvest Festival about an hour away from us. "It was only $10," she gloated as I unloaded the thing from the van. "Where do you want me to put this?" I asked, knowing what she would say.... "Oh, just put it in the garage, honey." :kiss: And so the buffet the garage has been on for the past several months continues. I have never seen a garage hold more crap.... let's see - all the camping gear, outdoor gear, snowtubing and snowboarding toys for the kiddos, gardening supplies (yep - I likes me my peppers, padre!), woodworking tools and table saw, several golf bags, bicycles, fireworks, MY grill/smoker, etc. And my wife laughed when I originally told her we needed a 60x40 instead of a 40x24. What was it she said, "How much room do you need for crying out loud?" Maybe I'll just take the latest project she found and put it in the bedroom! :P I'm sure that would fly!

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#51 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

I got quite a bit done on the 55 Fairlane last night. The front end of the frame is about completely bare save a couple brake lines. I did not have a coil spring compressor but I opted to leave the shocks INSTALLED until after I had disconnected the ball joints. This left some tension on the shocks but since I used my jack underneath the lower A arm to offset the pressure and the upper shock bolts were removed first. After that the jack was released and the coil just slid right out. I will disconnect the shocks from the lower A arms once I have them on the bench to remove the bushings.

Speaking of bushings, some of them were so old and worn out they literally fell off in my hands once the bolts were removed. The only difficult item to remove was the large shoulder bolt holding the front of the lower A arm to the crossmember. It was rusted pretty well and once I had it removed I noticed it was pitted badly. I think I have a good used one somewhere. The reason for the rust? As you can see from the photos, years ago a previous owner had made a repair to the crossmember by welding in good metal that seems to be thicker than stock. Unfortunately no weep holes were never drilled in thebottom so all these years the moisture had collected in the crossmember with no place to go. The crossmember is very stout and I beat on it with a hammer all night long, but I think I am going to have a welder friend of mine look at it and shore it up in a couple of places. I made a note to myself to drill a few holes when he is done. I also started disassembly/cleaning of a 1956 Ford steering column and gear I had purchased a few months back. I like the 56 wheel better, and from what I understand the 56 steering gear had a 3 tooth sector over the 55's two. Does anyone know why Ford had to put these shims in the FRONT of the Lower A Arm pivot point? I am wondering if they have anything to do with alignment (like the shims used on the Upper A Arm) or is this just something that Ford used because the crossmembers were never square? I don't think they have anything to do with alignment but I could be wrong on that.... I plan to put them back in because they were there when I disassembled the arm.  I did get a little hungry last night while working in the garage for a few hours and decided to break out the deep fryer and throw down with some homemade apple pies... yep - I put together the crust and all from scratch. You can see my kids tearing into these things. Nothing like a snack before the youngin's go off to bed! :P    If any of you have any tips on disassembling, cleaning, and inspecting the steering gear I would appreciate it. When I took off both of the covers of the gear housing last night, the gears themselves looked pretty good, I think I saw only 2 or 3 pits as I rotated the gears on the shaft and knuckle.

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#52 | |

|

Senior Member

Join Date: May 2010

Location: Willetton, West Australia

Posts: 478

|

The washers/shims are installed on the front bolts so that when you tighten the nuts on the control arms you are not spreading the arms. You fit the a arm to the back bolt first and then fit the fronts. Do not tighten the nuts until you have everything installed back on the car and it is sitting at it's settled ride height. If you tighten them with no weight on the front end, the first time you drive the car you will probably tear the rubbers apart.

__________________

Rick West Australia 1958 Ford Mainline Utility, 1955 Ford Tudor Sedan Quote:

|

|

|

|

|

|

|

#53 |

|

Senior Member

Join Date: May 2010

Location: Granite City, Illinois

Posts: 3,008

|

I think you will find that it is very, very difficult to re-install those washer-shims in front of the lower A-frame arms once the new bushings are installed. I gave up and left those off when I re-installed my suspension arms. Those are probably the only items I had leftover after re-assembly as I am very careful always to try to keep with the original design intent.

|

|

|

|

|

|

#54 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

Thanks for the replies fellas -- I was looking at the crossmember yesterday and decided to go into the depths of crossmember hell. Healthy repairs had been made to the crossmember before (20 years ago) with metal plates about twice as thick as stock. Unfortunately no one had thought at the time to drill weep holes for the water to drain out and I suspected that there was some rot. So, after showing a few photos to my welding buddy (that's his full time job) he said it looked ok and he would bring some plate over to weld to the crossmember so long as there was good metal to weld to. After removing the very front angled "bumper" with my cutting wheel, I snapped a photo or two of what was behind it...

Yep if you look at the photo of the bag of rust on the scale, you will see the readout - 2 lbs and 11 oz of rust and scale !!! :w00t: The irony in all this is that the metal from the repairs 20 years ago is as stout as it can be and I can take a hammer to it all day long. The crossmember itself is still very strong but I am glad I opened this up. I plan to sandblast the inside and get where I can. After that I will treat the rust and then paint. My welding buddy will come over and put good metal plate to cover the front from top to bottom and from the thick reinforcement of the shoulder bolts from side to side. The other side is not quite as bad but I will have him weld there too. I did try to remove the bushings from the lower A arms, but not having a shop press, I spent 30 minutes with a ball joint press, a hammer, and gorilla type force. I got one of the bushings to move about 1/4" -- that's it. Any tricks to removing these bushings or am I going to have to take them to a shop to have them all pressed out?

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#55 |

|

Member

Join Date: Jan 2014

Location: Belmont, Western Australia

Posts: 71

|

There are two ways to remove the bushes with out a press, you can either drill a series of holes in the rubber of the bushes and then hit the outer part of the bush as to distort it like squashing it and this is usually enough to distort and dislodge it so you can knock them out, or you can use a torch to heat them up and burn the rubber out and do the same this with the hammer to distort and then knock them out, to push them back in I use two pieces of pipe and a vice, put one piece on the receiving side of the bush so it can slide into place and not hit the jaw of the vice and use the other piece of pipe to push the bush in so the a arm doesn't hit the vice. Hope this makes sense.

cheers |

|

|

|

|

|

#56 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

Fellas thanks for the advice and ideas. I too decided to push out the inner bushing/sleeve by heating up the rubber (some of it was so worn it had just about disintegrated!) and just yanking it with a pair of pliers. After that I cut a deep groove in the ID of the metal bushing to get me started and then just simply tapped them out. One of them I obviously separated. It was not too difficult to say the least and now I can go ahead and blast those arms and then paint them up pretty. I barely nicked the edge of the ID on the arms, but I don't think it is going to be any big deal. Looks like those were the original bushings on the car.

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#57 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

My welding buddy talked to me the other day and he said he wants to get on the project so that motivated me to get out the sandblaster again and go to town on the metal in question. You can see the photos below (looking from the firewall) I only need a few plates welded in and we are good to go. Could I get another crossmember from a repro shop? Yes. Would I feel confident in getting the geometry right? No. :hehe: I am sure there is a good way to do that with the measurements and all, but I figure if my buddy is telling me that it won't take much to "shore it up" why bother - he's the metal man, not me. The front is pretty simply - one long piece and we are good to go. The rear will need 4 pieces as the lower metal is very solid and does not need to be replaced but the wall itself needs attention.

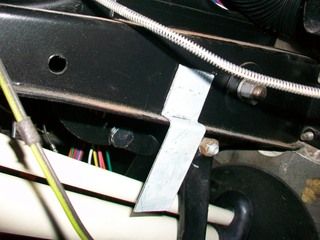

I also did some work on those front end parts as you can see... blasted with glass beads and painted with semi-gloss black Rustoleum. The center link was in very good shape and disassembled easily. It should be a breeze to put it back together. The other parts in the box are just the start to the rebuild of the front end of course - gotta get this thing back on rollin' wheels before I put the 292 and 3 speed overdrive in the car. The steering gear is ready for a new sector seal, worm and shaft, shims, etc. I soaked it in solvent in a parts washer for quite some time and then cleaned it thoroughly. I took a wire wheel to the exterior and painted it in semi-gloss Rustoleum as well. All of the parts I need for the rebuild are on their way and hopefully I can have that thing buttoned up by next weekend. Can't wait to feel that steering tighten up. The original was as loose as a goose!

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#58 |

|

Senior Member

Join Date: May 2010

Location: Phoenix,AZ

Posts: 1,417

|

About that cross member click on this: http://s200.photobucket.com/user/old...?sort=3&page=1 Here is the plan diagram to weld up your own,stronger than stock unit.

|

|

|

|

|

|

#59 |

|

Senior Member

Join Date: May 2010

Location: Australia

Posts: 362

|

One way to remove the suspension bushes without a press is to get a piece of pipe approx. 2 to 3 inches long that is slightly larger in diameter than the bush. Get a large heavy washer to sit on the end of the pipe and place them on one side of the bush.

On the other side of the bush you use a socket slightly smaller than the dia. of the bush, put a length of threaded rod through the lot with a nut each end and start winding one of the nuts. As you tighten the nuts the socket will push the bush out of the A arm into the pipe on the other side. To install the new bushes you reverse the process. |

|

|

|

|

|

#60 | |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

Quote:

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

|

#61 | |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

Quote:

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

|

#62 | |

|

Senior Member

Join Date: May 2010

Location: Phoenix,AZ

Posts: 1,417

|

Quote:

|

|

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#63 |

|

Junior Member

Join Date: Aug 2013

Posts: 4

|

I am searching for the trim piece that goes on the trunk under the trunk lock for my 55 but not having any luck. Does anyone have info where i might find this piece.

|

|

|

|

|

|

#64 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

My buddy Mike came over, looked at the crossmember, tapped around a bit, and told me he didn't think it needed to be replaced - let's weld her up! It didn't take him 20 minutes with my MIG 135 from Eastwood and Mike had it finished. We used 1/4" ad 1/8" plate cut to fit. He had good penetration throughout and I have already starting doing a little judicious grinding in a few areas to clean things up a bit. This thing is pretty strong and definitely stronger than stock. I have some Inner Frame Coating on the way from Eastwood, and will hopefully finish cleaning up the frame for paint soon.

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#65 | |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

Quote:

If you are searching for the "crown" emblem, check with dennis carpenter, concours parts, or Mac's... they might have that.

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

|

#66 |

|

Senior Member

Join Date: Nov 2013

Location: Portugal

Posts: 374

|

Sponsored Links (Register now to hide all advertisements)

|

|

|

|

|

|

#67 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

It has been some time since my last post, but I have good reason - believe me. There are things more important than our cars, that's for sure. However, the time I can spend in the shop is a good opportunity to meditate, relax, and unwind after dealing with so many people all day long and helping them with their problems. I have been known to crank up a good southern gospel music CD or even one my favorite sermons from a preacher of yesteryear and have at it in the garage with all the work (er, fun).

Back to our blog After the cross member was welded up by my friend Mike, I decided to smooth it up a bit and paint it with 3 coats of Rustoleum. I like the semi-gloss sheen on the frame and will use that for the sub assemblies as well.   I finally got back in the shop last night after spending a few weeks with other priorities. First up was the steering gear box and the rebuild. I had all of the parts I needed. The worm gear on the shaft was a used unit I found, but it was very near pristine on the grooves and fit perfectly. The bearings were already in good shape so I cleaned and kept those. I ordered a new seal for the sector shaft that holds the pitman arm. I got it from fleabay for something like $4 shipped and the thing fit very, very well. It was a US brand name seal, but memory fails me at the moment to tell you which one.           When I got it all completed, I was scratching my head over an "extra" part that I did not recall. After a few minutes it dawned on me that the large washer was actually the keeper for the original rubber seal for the sector shaft. I had forgotten that the seal was actually two pieces, so that large washer was obviously not need because the new seal was now one piece. The shim pack was interesting to deal with. I looked at the original number and thickness of the shims that were installed originally and I tried to install new shims that were an exact match. After torqueing down the bolts I spun the steering shaft and thought it seemed loose. As a matter of fact it was so loose that it actually had a little but of runout (vertically). "Well that can't be right," I muttered. After I looked at it crosseyed for a moment... "Hey bonehead! The replacement worm gear - that's what making the difference here." So I removed one of the original 3 shims and just checked to see what would happen if there were no shims.... TIGHT as it could be! No wonder there is a little frustration over getting the pre-load right. I guess it is a little tricky. I went through my pack of shims and just kept working on it until I found 3 that didn't have any play on the runout vertically but still kept it spinning "right"... now, what "right" actually is, I have no way of knowing. Someone had suggested using Ford's shop manual for the load, but that is with the leverage of the steering wheel. And... I don't have a torque wrench that goes to a very small inch/pounds. I guess I need a spring scale anyway. However, I would like to get this right on the bench before install... any ideas? I greased the gears up pretty good and wrapped it all in plastic until it is installed. I have gear oil for it 80w90. While I was at it I decided to put together the drag link. It was already in good shape - it just needed to be cleaned up and greased really well. I also need to get a new zerk fitting for the thing.   Things were going so well I decided to tempt fate and dismantle both upper control arms. I needed heat on one occasion but things went reasonably well. Again, some of the rubber was about ready to disintegrate so it was a no brainer to replace all of this stuff up front.   For those of you that really know your stuff.. yes there are 3 large washers per upper arm. The third is in the box.

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! Last edited by Hot Rod Reverend; 11-19-2014 at 05:50 PM. |

|

|

|

|

|

#68 |

|

Senior Member

Join Date: Nov 2013

Location: Portugal

Posts: 374

|

Looking very good Reverend.

|

|

|

|

|

|

#69 |

|

Senior Member

Join Date: May 2010

Location: Granite City, Illinois

Posts: 3,008

|

HRR, are you going to leave the "cow-catcher" off of the frame front crossmember? Kinda late now to weld it back on since you got the frame all painted up real nice.

|

|

|

|

|

|

#70 |

|

Senior Member

Join Date: May 2010

Location: Granite City, Illinois

Posts: 3,008

|

I was able to stick a spray can of Rust-o-leum black up in those corners of the frame since it is too small to work a brush in there.

|

|

|

|

|

|

#71 |

|

Senior Member

Join Date: May 2010

Location: Granite City, Illinois

Posts: 3,008

|

Oh yeah that long trim piece at the bottom of the trunk lid for the Fairlane models at one time was being reproduced by one of the resto parts suppliers. I think it was Concours and they wanted about $400.00 for it.

I left that part off of my car because it is very badly pitted and it is still laying on top shelf in the garage. I'd hate to think what they would want to fill, grind and rechrome that piece. |

|

|

|

|

|

#72 |

|

Senior Member

Join Date: Dec 2010

Location: p.e.i.

Posts: 1,060

|

anyone else have a copy of practical auto restoration.the resurrection of vicky a 55 crown vic put out by cars and parts.a good book put out about 25 years ago.

|

|

|

|

|

|

#73 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

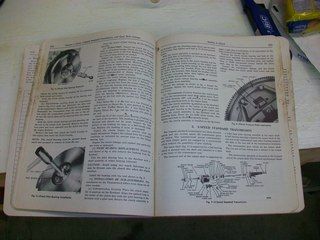

yes I have a copy... good photos and such. Sometimes lacking on step by step procedures but for what it is if you have a 55 or 56 it is a real treasure to own. Handy references too for aftermarket part numbers and the like. I would have liked to have seen them do something more with the transmission and/or the rear end in that whole process but it was nice nonetheless.

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#74 |

|

Senior Member

Join Date: May 2010

Location: Lancaster, CA

Posts: 916

|

You are one of the few that caught that! Yep - I decided to leave it off since we beefed it up so much. I really don't see the point of it unless there was some idea of a front impact and absorbing the force? the metal is so thin right there I really didn't see the need.

__________________

Lancaster, California Visit hotrodreverend.com to view hundreds of pictures and videos of the build of the 1955 Ford Club Sedan! |

|

|

|

|

|

#75 |

|

Senior Member

Join Date: Dec 2010

Location: p.e.i.

Posts: 1,060

|

the force was mud and ruts back in the day these cars travelled of roads you wouldnt put a tractor on today.where i live the ruts would be a foot deep and then it would freeze and when you fell into these ruts smash crash.56 was the last year that ford closed the engine in underneath.anyone still have that on their cars.most have been thrown away.

|

|

|

|

|

|

#76 | |

|

Senior Member

Join Date: May 2010

Location: Granite City, Illinois

Posts: 3,008

|

Quote: