08-26-2014, 07:41 PM

08-26-2014, 07:41 PM

|

#10

|

|

Senior Member

Join Date: May 2010

Location: Windy City

Posts: 2,919

|

Re: How deep are the 14 holes in the block?

Re: How deep are the 14 holes in the block?

Quote:

Originally Posted by rocket1

who sells that 1/2 stud? I have a block where somebody installed the heli-coil about 3 deg. of vertical.

|

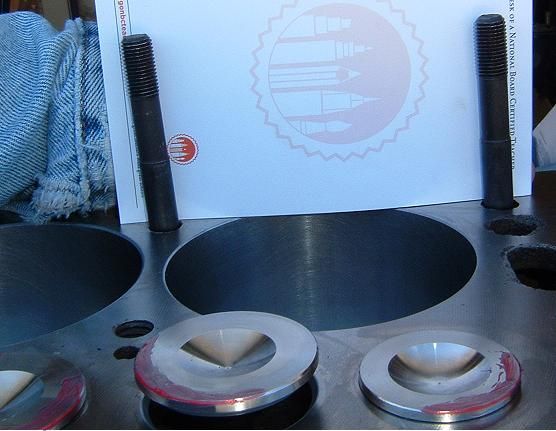

Helicoils are very compliant because they are a wound spring and the threads can move independently. Here's a few crooked ones (not my work!!) in an engine I rebuilt. If you apply some force to the stud with a pipe and deliver a few taps with an 8 oz machinist's hammer to the enlarged diameter base of the stud, they will straighten without bending the stud.

The special helicoil taps leave a lot of 'slop' clearance to thread the spring into, one of the reasons I'm not overly partial to them. I did proof the studs by torquing a sleeve to 65 ft-lbs. Typical of newly installed helicoils, they felt a bit spongy 'till about 50 ft-lbs, then they stop moving against the clearance and feel solid. Proofing the repair with a sleeve and torque wrench saves learning after-the-fact if it will hold.

Either a solid Locknstitch FPS series or Time-sert solid 'bigsert' is a far superior option to correct a hole problem but if there is already a helicoil in place and it is slightly off-vertical I wouldn’t immediately reach for a bigger drill and tap.

|

|

|