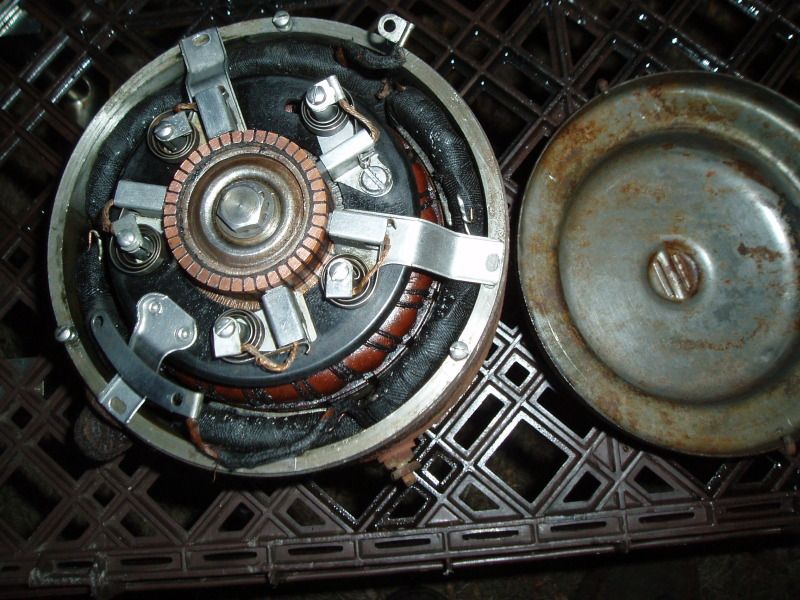

I took some gas and a brush and cleaned up my nice (on the inside) original powerhouse. You can see how much nicer it looks when it's left original instead of a heavy coat of Glyptal brushed all over the armature, and black paint on the field coils. Glyptal would also inhibit cooling of the armature. The last picture shows the damage caused by someone leaving it outside. What a shame, but I think I have a good case for it. Just for kicks I should sand smooth the V of the pulley and run it as is.

That ebay powerhouse looks like it was dipped or heavily brushed with Glyptal, then the armature appears to have been sanded on a belt sander. This is also poor practice. The armature should NOT be sanded nor turned on a lathe, as it will increase the air gap between the armature and field poles, which will decrease output. If the armature has rust, just wire wheel it off. The most rust I've seen on one is just a light coat of surface rust, which came right off on the wire wheel.

Someone asked about the smaller diameter of the commutator and how it affects performance. It would very slightly increase the degrees of rotation the brushes are in contact with each commutator bar, but the change would hardly be measurable. After I install the EVR I will check it against another good 3 brush. The powerhouse has good output and I'm sure it will be fine, but I sure don't like what was done to this one needlessly.