Sorry for the long post but it's necessary to reflect the information.

The polarity really doesn't mean anything, at least in reference to the stock setup. Regarding your solid state voltage regulator, well... that might make a difference depending if it can work with reverse polarity. Swapping the wires on the back of a stock gauge will have absolutely no effect.

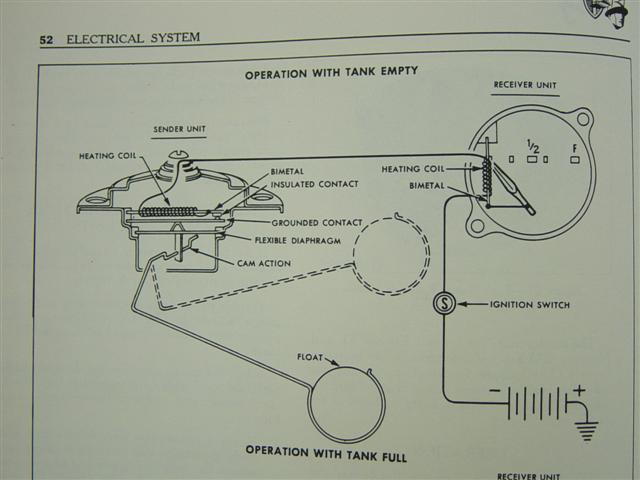

The gauge works by current heating a bimetallic strip that is connected to the needle. As current flows through the strip it heats up and causes the needle to move as it deflects. In order for the gauge to read correctly and not be affected by voltage and current variances the original sending unit included another bimetallic strip that would click on and off (speed of this action in direct proportion to the current flowing through it) thereby regulating the current and voltage, much like a turn signal flasher. The more current, the more heat and the longer the open time thereby reducing how much current is available at the gauge. The float arm, affected by the fuel level, increased/decreased the position of the point arm thereby altering the duration of time that current was delivered to the gauge and changing the needle position as a result. Now you can see how 6 or 12 volts was inconsequential as it is regulated. Being everything is operated by heating strips, polarity has no more affect than which way a light bulb is connected.

HOWEVER, be very aware of your wiring - I found out my truck's PO made a mistake in his wiring and sent voltage through the sending unit which burned the nichrome-wrapped card. It got hot enough that it melted the plastic the wire was wrapped around. How it never caused an explosion is just luck on his part (maybe even mine, as I drove it from Toledo to Louisville when I bought it.) It must have been submerged in the fuel as I doubt that if it had been that hot in an air-fuel mix it wouldn't have sent one of us on a trip to meet Alice Kramden on the moon.

So... the sending units sold these days do not include the regulator - you have installed one to make up for that. However, the sending units aren't exactly calibrated for us, they're just a kind of a generic make-do/it must be you/it must be your car/etc. product. The resistance coil in the sending unit you have is wound to provide a range of resistance that is close, but not quite close enough, to result in an accurate reading. Using a Kent-Moore instrument gauge tester (J-24538-B) I found the following readings applied to my '53 F-100 (resistance readings verified with a Fluke VOM to all be within 0.1Ω):

Full (needle centered on mark) 18Ω

21Ω

3/4 23Ω

25Ω

1/2 28Ω

32Ω

1/4 35Ω

39Ω

Empty (centered on mark) 43Ω

These readings were taken with the engine idling so as to provide a stable 7.15 volts. I moved to the settings both up and down and from 1/8 spans and 1/2 spans to reach the readings. I've measured both "Must be used with original gauges ONLY" style sending units (standard nichrome wrapped and 'electronic'.) Both measured identically (I wish I had written the measurements down but they were in the 22-98Ω range as my memory recalls.) The spec sheet included with the tester shows Ford fuel units to spec at 10-76Ω but make no mention of years or K-S or CVR type units. My truck has had the dash harness replaced by PO and I've installed a new ground to frame wire. I have the stock (replacement) running board tank ('53) and it measures 11" deep. I made the specific arm length adjustments as directed (DC 'electronic' version sending unit) and ended up exactly in the same place I was with the 'standard' replacement unit. I sped up the engine RPM to allow for 7.56 volts and measured about an 1/8 difference in gauge range as a result. Realizing that the missing regulator in the original sending unit is the reason for the gauge inaccuracy I purchased some adjustable electronic regulators on Amazon for ~$6.

I haven't yet had the chance to install one and report back what voltage and, if necessary, re-adjustment to the float arm was necessary to make it all come together. However, I'm scheduled off next week and, weather permitting, it's on my short list of things to do.