|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Senior Member

Join Date: May 2010

Location: Portland, Oregon

Posts: 5,909

|

Some previous owner installed a helicoil for one head stud (#2) in such a way that that stud is off vertical by about 4 degrees. Can I remove the old helicoil (if so, how?) and install one correctly, or, as I suspect, was the hole drilled off kilter and replacing the helicoil would have no effect?

Or, is it just a bigger hammer problem?  Should I install the stud and attempt to coax it back to vertical, either by torqueing it or by rapping it with a hammer? I don't like these options, but what's a guy to do? Should I install the stud and attempt to coax it back to vertical, either by torqueing it or by rapping it with a hammer? I don't like these options, but what's a guy to do?

__________________

Ray Horton, Portland, OR As you go through life, keep your eye on the donut, not the hole.

|

|

|

|

|

|

#2 |

|

Junior Member

|

There are thread inserts of a solid type that you could recover this hole to vertical and it would be right, but slightly bending a new grade 8 stud would not alter it's strength.

Caution on bending in an unsupported hole. |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#3 |

|

Senior Member

Join Date: May 2010

Location: Camino, CA.

Posts: 3,086

|

When that happened to me, I tightened the stud and marked the side the direction it was leaning. Then I removed the stud, put it in my vice, put a nut on it, and hit it the direction I wanted it to go. The nut is to protect the threads. Fixing my mistakes is my specialty.

|

|

|

|

|

|

#4 |

|

Member

Join Date: May 2010

Location: South Carolina

Posts: 92

|

I would remove the helicol and retap the original thread as best as you can. Get a tangless threaded insert not a helicol. McMaster-Carr.com is a good source. You will have to go smaller on the bolt though. The outer thread will match the size of the original hole. The inner thread will be a new smaller size. The helcoil you have is like a spring and it was likely forced into really bad threads to start off with. Just a idea.

|

|

|

|

|

|

#5 |

|

Senior Member

Join Date: May 2010

Location: Portland, Oregon

Posts: 5,909

|

Glenn: "Fixing my mistakes is my specialty."

Now that's funny right there.

__________________

Ray Horton, Portland, OR As you go through life, keep your eye on the donut, not the hole.

|

|

|

|

|

|

#6 |

|

Senior Member

Join Date: May 2010

Posts: 1,262

|

Sponsored Links (Register now to hide all advertisements)

An OVERSIZED heli-coil was installed - five of them - and then installed standard size bolts. Good Luck! |

|

|

|

|

|

#7 | |

|

Senior Member

Join Date: Oct 2010

Location: 40 Mt.Vickery Rd. Southborough,MA 508-460-0733

Posts: 352

|

Quote:

Poor quality remains long after the sweetness of low price is forgotten ... www. jandm-machine.com |

|

|

|

|

|

|

#8 |

|

Senior Member

Join Date: Oct 2010

Location: 40 Mt.Vickery Rd. Southborough,MA 508-460-0733

Posts: 352

|

To answer the original question with a permanent repair though may be expensive.

Is to use the Lock N Stitch method of thread repair. This repair is a threaded plug that once installed duplicates the threads of the existing hole. http://www.locknstitch.com/inserts.htm The other back yard machinist solution is to drill the damaged hole bigger to 1/2-13" dimensions and then machine a threaded plug similar to the lock n stitch and then install with lock tight. Thereby recreating the existing straight threads. Hopefully you have a proper way of drilling this straight or else take it to the professionals. |

|

|

|

|

|

#9 |

|

Senior Member

Join Date: May 2010

Location: Windy City

Posts: 2,919

|

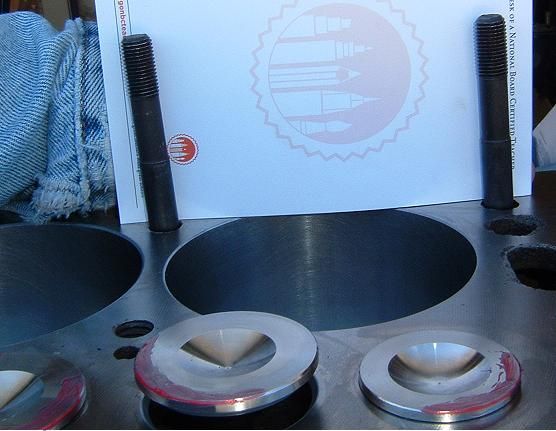

Helicoils are very compliant because they are a wound spring and the threads can move independently. Here's a few crooked ones (not my work!!) in an engine I just rebuilt. A few taps with a hammer and they were straight without bending the stud.

The special helicoil taps leave a lot of 'slop' clearance to thread the spring into, one of the reasons I'm not overly partial to them. I did proof the studs by torquing a sleeve to 65 ft-lbs. Typical of newly installed helicoils, they felt a bit spongy 'till about 50, then they stopped moving against the clearance and felt like solid originals.

|

|

|

|

|

|

#10 |

|

Senior Member

Join Date: Oct 2012

Location: Whangarei, New Zealand

Posts: 298

|

__________________

Allan '29 Tudor, Canadian RHD Whangarei, NZ "Duct Tape can't fix stupid, but it can MUFFLE the sound" |

|

|

|

|

|

#11 | |

|

Senior Member

Join Date: May 2010

Location: Portland, Oregon

Posts: 5,909

|

Quote:

__________________

Ray Horton, Portland, OR As you go through life, keep your eye on the donut, not the hole.

|

|

|

|

|

|

|

#12 | |

|

Senior Member

Join Date: May 2010

Location: Windy City

Posts: 2,919

|

Quote:

If that fails, as suggested above, either a solid Locknstitch FPS series or Time-sert solid 'bigsert' is an option to correct the crooked hole problem. |

|

|

|

|

|

|

#13 |

|

Senior Member

Join Date: May 2010

Location: Portland, Oregon

Posts: 5,909

|

Thanks Mike! I'll try it.

__________________

Ray Horton, Portland, OR As you go through life, keep your eye on the donut, not the hole.

|

|

|

|

|

|

#14 |

|

Senior Member

Join Date: May 2010

Location: Portland, Oregon

Posts: 5,909

|

Allen: Good to know about Timesert also. I may have to resort to that.

__________________

Ray Horton, Portland, OR As you go through life, keep your eye on the donut, not the hole.

|

|

|

|

|

|

#15 |

|

Senior Member

Join Date: Jan 2012

Posts: 249

|

I had one like that picture come into my shop last week....a good slap with my hammer straightened it up fine.... although I would not do that with Grade 8 head studs...most studs are Grade 5 and easy to bend..

another trick you could do it remove the stud put the head in place then double nut the head nuts and screw the stud back in...it works fine...there is some slop in Heli-coils and 4 or 5 degrees is not bad...would not do it if they were really out of alignment.... Also...you should dip the end of every stud in something like Permatex (non hardning) to seal the threads....or water will seep up to the head nuts...that protects the studs from corrosion. Joel |

|

|

|

|

|

#16 |

|

Senior Member

Join Date: May 2010

Posts: 319

|

Timeserts use the same STI type of thread, it's not normal or used onany other insert I know of. If you think about it the outside of a helicoil has the same pitch as the inside but the diameter is PLUS the wire diameter sort of.

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 03:03 PM.

Linear Mode

Linear Mode