|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

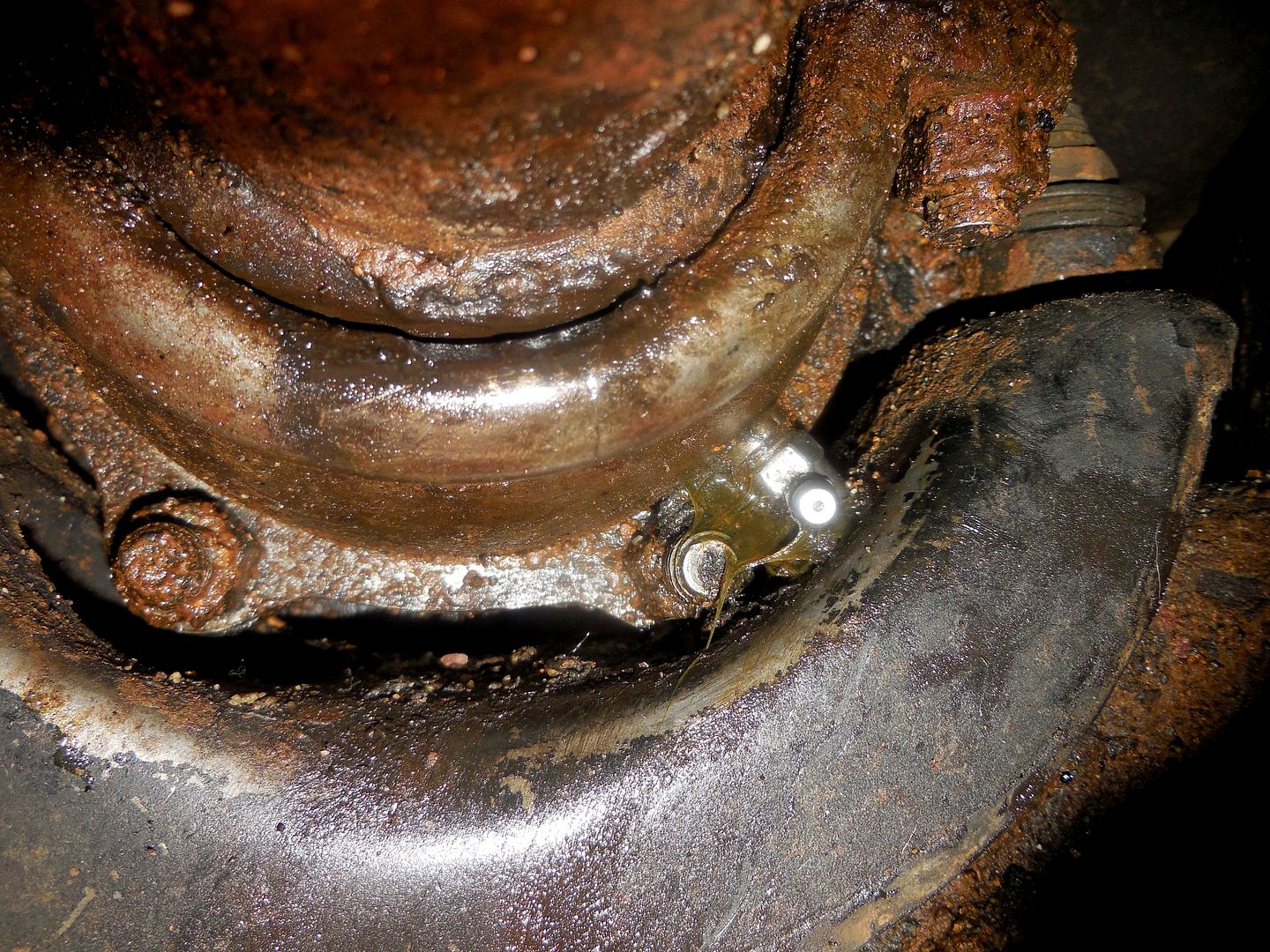

47 sedan U-joint zerk. It's a 90° fitting but is too close to the frame member to get a grease gun onto.

I've tried to find a little elbow that would screw in its place that I could put a tube on to extend it beyond the frame member but haven't found one. Anyone else had this problem and found a solution?

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness Last edited by Old Henry; 03-31-2014 at 03:35 PM. |

|

|

|

|

|

#2 |

|

Senior Member

Join Date: Jun 2011

Location: central Iowa

Posts: 484

|

I think you can get extensions for zerks.

__________________

Louvering, bias ply tire-truing, metal shaping and forming, lathe and mill work, member shop HAGERTY Ins. expert repair network. High quality paint work in Iowa. |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#3 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

I have looked at length on the internet for those. All I find as far as an extension is one that extends straight out. I've not seen any 90° ones. That would be perfect if it could be found. If anyone knows where one is available I'll jump at it.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

#4 |

|

Senior Member

Join Date: May 2010

Location: Wisconsin, USA

Posts: 8,995

|

Has anyone else had this problem and found a solution?

Turn it to the left or right a bit. It's a close fit, but a standard grease gun will fit.

__________________

"I can explain it for you. However, I can't understand it for you". |

|

|

|

|

|

#5 |

|

Member

Join Date: May 2010

Location: grass valley ca.

Posts: 75

|

same prob. when i had to replace engine last aug. i did what kube said an put 3/4 spacers under trans mounts to raise it up a bit. love your trips you take. i put a lot of miles on my merc too. reguards dick t.

|

|

|

|

|

|

#6 |

|

Senior Member

Join Date: Jun 2012

Location: Long Island,NY

Posts: 1,555

|

Sponsored Links (Register now to hide all advertisements)

|

|

|

|

|

|

#7 |

|

Senior Member

Join Date: May 2010

Location: Florence Ma.

Posts: 2,404

|

They make needle end to go on your grease gun you push in the little ball on the fitting and keep pushing a little pressure inward and pump the grease like normal.

|

|

|

|

|

|

#8 |

|

Senior Member

Join Date: May 2010

Posts: 2,173

|

You need a 1/16" NPT street elbow something like this.

|

|

|

|

|

|

#9 |

|

Senior Member

Join Date: May 2010

Location: Canada Where it snows

Posts: 2,058

|

Looking at your pic it appears that the zirc threads into the elbow.And the elbow threads into the casting. Is that the case?

R |

|

|

|

|

|

#10 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

|

#11 |

|

Senior Member

Join Date: Jul 2011

Location: SF Bay Area

Posts: 6,641

|

What hardware store doesn't have pipe fittings?

__________________

Alan |

|

|

|

|

|

#12 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

I'm replacing the rear tranny mount thinking that maybe it's shrunk and let the tranny drop down just enough to cause my problem. If that doesn't solve it and I can't find the street L to put a zerk on I'll probably put enough spacers under the tranny mount to raise it up enough to get my grease gun on it.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

#13 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

|

#14 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Went to ACE hardware and Home Depot. They had plenty of steel and brass pipe fittings but none as small as I needed. They stop at ¼".

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

#15 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

That's what it looks like but I tried to remove the zerk and it would not so it may just be cast to look like that.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

#16 |

|

Senior Member

Join Date: May 2010

Location: Canada Where it snows

Posts: 2,058

|

I assume you used a 1/4" drive socket on it.

The zirc threads should be 1/4 x 28 tpi looking at the pic. Did you try the removal on or off the car. If it comes out here is one option. http://www.saeproducts.com/taper-thr...-fittings.html R |

|

|

|

|

|

#17 |

|

Senior Member

Join Date: May 2010

Location: Ft Mohave,Az

Posts: 1,987

|

Type in McMaster-Carr then do the search for zerk grease fittings

|

|

|

|

|

|

#18 |

|

Senior Member

Join Date: May 2010

Location: Solihull, England.

Posts: 8,749

|

Could you not just put a spacer between the mount and the trans to raise it just enough to get good access? 1/8 to 1/4 inch should do it??

Mart. |

|

|

|

|

|

#19 |

|

Senior Member

Join Date: May 2010

Location: Canada Where it snows

Posts: 2,058

|

This may get you out of the woods.

http://www.skywaytools.com/products/...ler-Extension/ http://www.quill.com/lincoln-hydraul...bs/269527.html http://www.zipzab.com/Lincoln-5852-p/2021-5208.htm R |

|

|

|

|

|

#20 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

If I can find a street L that will replace the elbow that's on there I, hopefully, can screw in an extended zerk fitting that I've found.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

|

#21 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

That will be my last resort if I can't get anything else to work. I'm a little concerned about any possible compromise of that connection since the whole car is pushed by it.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness Last edited by Old Henry; 03-29-2014 at 11:18 PM. |

|

|

|

|

|

#22 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Thanks. Took a look. Didn't see any right angles with extensions.

Thanks anyway.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#23 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

Thanks for the info.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness Last edited by Old Henry; 03-29-2014 at 08:49 PM. |

|

|

|

|

|

|

#24 |

|

Senior Member

Join Date: Aug 2012

Location: Perth, Western Australia

Posts: 2,687

|

Can you get to the one at the top, should be one in each clam? Just pump through that one. Let us know how you go replacing the mount. It's a job on my to do list.. I take it you have to drop the back end out to do it ?.damn..

__________________

"Came too close to dying to stop living now!" |

|

|

|

|

|

#25 |

|

Senior Member

Join Date: May 2010

Location: Ft Mohave,Az

Posts: 1,987

|

OK try this site;

www.saeproducts.com/grease-fitting-accessories.html |

|

|

|

|

|

#26 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Sponsored Links (Register now to hide all advertisements)

Quote:

I don't know if the tranny mount can be replaced by just loosening it and jacking up the engine and tranny off of it to replace it without pulling the torque tube off. My challenge, even with the tranny out, is that there are no heads to the bolts that hold it on through the frame and my bolts are turning when I try to remove the nuts. So, it looks like I'm going to have to dig into that rubber that the bolts are molded into to get a hold of them with vice grips to get the nuts off to replace it.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

|

#27 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

Looks like I've got to call them to order. I'll do that first thing Monday. Hopefully they don't give me guff about only selling to mechanic businesses yada yada. Thanks again. Looks like I've got to call them to order. I'll do that first thing Monday. Hopefully they don't give me guff about only selling to mechanic businesses yada yada. Thanks again.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

|

#28 |

|

Senior Member

Join Date: May 2010

Location: Orland Park,IL

Posts: 1,402

|

Henry, your second photo shows the thread going into the clam shell as larger than the thread of the zerk where it screws into the top of the fitting. The zerk itself is either pressed into the fitting, or it may be threaded. If threaded it is 1/4-28, but the end in the clam shell is threaded 1/8 NPT, or 1/8 pipe. Looking at the chart linked to in post #8 shows street els and the 1/8 NPT el has an "S" dimension of 7/8" or .875 with that dim. shown to the center of the female thread. The zerk on your car has an overall length of 53/64", or .828 so it is already much shorter than any combination of street el you will locate. The street el from that chart is Swagelock brand and being an industrial fitting I'm sure it has a shorter overall length than the average plumbing street el that you might find at Ace Hardware.

After 67 years your trans mounts had to have compressed a bit. I think the solution is replacement or shimming. Or at least try re-orienting the zerk as Kube suggested. |

|

|

|

|

|

#29 | |

|

Senior Member

Join Date: May 2010

Location: Orland Park,IL

Posts: 1,402

|

Quote:

|

|

|

|

|

|

|

#30 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

|

#31 |

|

Senior Member

Join Date: May 2010

Location: Orland Park,IL

Posts: 1,402

|

Yes, I had already looked there too, but everything I see in the size required will extend out (from the clam shell) further than a regular zerk. The need for a 90* elbow is agreed, but they measure too tall from what I see. I'll be interested to see how this plays out.

Which fitting do you intend to purchase? If you measure the male thread on the zerk you removed does the thread measure around 1/4" diameter, or is it just under 3/8"? |

|

|

|

|

|

#32 |

|

Member

Join Date: Aug 2010

Location: Brisbane, Australia

Posts: 44

|

Couldn't you just drill and tap a hole in the center at the bottom where there is more room and move the elbow and grease nipple across to that, and then just plug up the other original hole with a grub screw? Would that not allow you more room?

|

|

|

|

|

|

#33 |

|

Senior Member

Join Date: May 2010

Location: Solihull, England.

Posts: 8,749

|

I looked at the parts I have in my shed and the lower mount looks different to the mount you have. Are you sure the rear mount you have is correct? The area below the two lower bolts is depressed to give more clearance. I cannot see any reason why simply adding a washer each side until enough clearance is achieved would be a problem. I would look at it as the first resort not the last.

I cannot see how any of the grease fitting adaptors pictured would be as compact as the one you have. What I would do, is try and cheat the situation a little. I would see if the existing fitting would screw in not quite one turn, so the thing is further in by one thread pitch, and the angle of the fitting is approached from a more central position where there is marginally more clearance. If it does not want to turn, I would remove it and carefully retap the hole until it allows the fitting to go in further. I would then offer it all up and add spacer washers as necessary until it fits together ok giving enough clearance. I'm not being funny, but this is not a massive problem that should have people across the globe scratching their heads. In the time it has took me to write this I could have fixed it for you. Mart. |

|

|

|

|

|

#34 | |

|

Senior Member

Join Date: May 2010

Location: Wisconsin, USA

Posts: 8,995

|

Quote:

I think the fellow that suggested the mount was worn out hit it on the proverbial head. With all that oil leaking all over the place, the rubber has no doubt been compromised, softened and crushed.

__________________

"I can explain it for you. However, I can't understand it for you". |

|

|

|

|

|

|

#35 |

|

Member

Join Date: May 2010

Posts: 75

|

I just ground down the ends of the grease gun to make it thinner and worked allright.

|

|

|

|

|

|

#36 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

It was a great idea anyway. Guess I'll have to do one of the other options. Probably shim the tranny mount up a bit. It was a great idea anyway. Guess I'll have to do one of the other options. Probably shim the tranny mount up a bit.If I wanted to keep searching, what size is the threaded hole that I'm looking to fit something into? 1/4"-28 or 1/8" NPT (the only two sizes that source sells)? Or, something else? Here's my fitting on a ruler:

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness Last edited by Old Henry; 03-31-2014 at 03:27 PM. |

|

|

|

|

|

|

#37 |

|

Senior Member

Join Date: Sep 2013

Location: Troutman, NC

Posts: 119

|

You have a 1/8 pipe thread fitting in the picture

|

|

|

|

|

|

#38 | ||

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

1. I'm not sure there is more room at the bottom than at the 4:00 position. 2. At the present location there is a shoulder built up on the outside of the clam to keep the zerk from penetrating the inside surface where it would rub on the torque tube bell. Drilling a new hole anywhere else would allow that undesirable penetration. Quote:

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness |

||

|

|

|

|

|

#39 |

|

Senior Member

Join Date: May 2010

Location: Florida and Penna.

Posts: 4,471

|

The threads are 1/8 NPS. Try a jack under the trans when you grease it. Once greased with a low drop point grease it will be years before it will need it again. G.M.

__________________

www.fordcollector.com |

|

|

|

|

|

#40 |

|

Senior Member

Join Date: Jul 2012

Posts: 586

|

Does anyone know what they did back in the day? These cars did not just roll off the assembly line. There must have been a solution when they were common.

|

|

|

|

|

|

#41 |

|

Senior Member

Join Date: May 2010

Location: Solihull, England.

Posts: 8,749

|

|

|

|

|

|

|

#42 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

My thinking is that when the tranny mount is new it holds the clam up high enough to get the grease gun on the zerk but over time it may compress just enough to lower the clam zerk down too close to the frame. Mine tranny mount was new 50,000 miles and 4½ years ago so maybe it's worn down over that time. I don't know. I've ordered a new one and when it comes I'll compare both carefully to see what differences if any. If they're identical I'll know that's not the correct answer.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness Last edited by Old Henry; 03-31-2014 at 06:31 PM. |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#43 | |

|

Senior Member

Join Date: May 2010

Location: Northeast Pennsylvania

Posts: 1,582

|

Quote:

I'm not familiar with the clamshell on a closed drive, but perhaps you could flip it so the grease fitting is on the top instead of the bottom? |

|

|

|

|

|

|

#44 |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

To jack up the transmission to get what grease I put in a month ago I had to remove the floor, loosen the transmission mounting bolts and jack it up. Others have suggested putting the zerk on top but that means removing the floor every time it needs greased which is every 1,000 miles or more than once a month for me as much as I drive. Removing the floor of my car requires removing the clutch and brake pedals, disconnecting the gas pedal, removing the floor mat, removing the padding underneath it, removing the water barrier underneath that, removing the radio foot control, removing all screws that hold the floor down, and removing the floor to put the grease in then reversing the procedure when done. Hope I can find a better alternative than that but thanks anyway.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

#45 |

|

Senior Member

Join Date: May 2010

Location: Solihull, England.

Posts: 8,749

|

Hang on.

The tranny mount bolts solidly to the ears of the transmission rear mount. the clearance between the rear of the trans and the trans mount does not change if the rear mount rubber goes soft. The whole shebang may sit lower relative to the frame, but the critical clearance we are looking at here does not change. If yours is a repro rear mount, who is to say if the clearance is the same as the genuine ford mount it rolled off the line with? If the clearance of that fitting is not adequate, it is because the rear mount is wrong. Not worn, wrong. If something is wrong it needs to be put right. In this case, a new rear mount might be the answer. It may be that the new rear mount is the same as the one you have. I will repeat the advice I offered twice already. Add washers between the ears of the trans mount and the rear mount until enough clearance is gained to get access to the grease fitting. Please stop agonising over this and just put into place a simple fix that does not involve protracted floor removal and messing about. here's a novel solution: Why not just carve a chunk out of the rear mount to give clearance? They are a replaceable item, around 25 bucks. get a new one, set it up on the trans as a dry assembly with the clam shell halves in place and grind a chunk out of it. It may be that the new mount gives enough clearance out of the box. Mart. |

|

|

|

|

|

#46 |

|

Senior Member

Join Date: Sep 2013

Location: Dighton, Mass

Posts: 1,230

|

Sponsored Links (Register now to hide all advertisements)

this on the grease gun it is slid in sideways. I have a couple zerks on a backhoe, impossible to grease until i found this at Napa. best i can explain.. |

|

|

|

|

|

#47 |

|

Member

Join Date: Aug 2010

Location: Brisbane, Australia

Posts: 44

|

Why don't you just replace the mount, and while the old mount is out.. grease it up good.. put new mount in and forget about it?

Or do what mart said and the three washers ontop of the trans mounting ears put them underneath the mount instead. Sounds like you are overthinking such a simple problem.. |

|

|

|

|

|

#48 |

|

Senior Member

Join Date: May 2010

Location: Gerrardstown, WV

Posts: 2,265

|

Why do you grease it every 1000 miles? Is it leaking out? Once filled, it should last a long time.

|

|

|

|

|

|

#49 |

|

Senior Member

Join Date: May 2010

Location: Northeast Pennsylvania

Posts: 1,582

|

Henry,

If it troubles you so (and it sounds like it does), remove the clamshell and the zerk, weld up the old hole, drill and tap a new hole in a different place that's more accessible. |

|

|

|

|

|

#50 |

|

Senior Member

Join Date: May 2010

Location: East Hartford, Ct

Posts: 5,898

|

Is it my imagination or an optical illusion or is the tranny shifted to the passenger side.

If shifted maybe a slight nudge with a pry bar would give enough clearance to access the fitting.

__________________

DON'T RECALL DOING SOMETHING FOR MYSELF BASED ON SOMEONE ELSE'S LIKES OR DISLIKES |

|

|

|

|

|

#51 |

|

Senior Member

Join Date: May 2010

Location: new britain,ct 06052

Posts: 9,390

|

Do as Mike51Merc says. JMO

Paul in CT |

|

|

|

|

|

#52 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

Right now everything but the engine is off of the car waiting for parts coming from Mac VanPelt to rebuild the drive line, transmission, and clutch. Before I reinstall the transmission I will bolt the clam shell to the rear bearing retainer on the transmission and bolt it down to the new tranny mount and see what clearance I have for the zerk and go from there. It may well be that the mounting holes are big enough to "cheat" the whole thing to the driver's side and create enough room without anything else. I like it better than shimming up the tranny on its mount. Thanks for the idea.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness Last edited by Old Henry; 04-01-2014 at 11:28 AM. |

|

|

|

|

|

|

#53 |

|

Senior Member

Join Date: May 2010

Location: Coral Springs FL

Posts: 10,934

|

Will a 45 degree zerk will work?

https://www.google.com/search?q=45+d...sm=93&ie=UTF-8 Or maybe a street elbow? http://www.lincolnindustrial.com/cat...ic/pg02-21.pdf But in the end, I would also first try 51Merc's idea. Last edited by 19Fordy; 04-01-2014 at 11:15 AM. |

|

|

|

|

|

#54 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

|

#55 |

|

Senior Member

Join Date: Feb 2011

Location: Buchanan, MI

Posts: 676

|

Three pages of suggestions, sounds like Henry just likes to type.

PUT IN A NEW TRANS MOUNT, works for 38,000,000 other Fords. |

|

|

|

|

|

#56 |

|

Senior Member

Join Date: May 2010

Location: Brandon Mb Canada

Posts: 133

|

As has been suggested install new zerk 90* make sure that coupler on grease gun is the small diameter one, and a good one , if need be grind mount as needed Laurie

Last edited by Teich; 04-01-2014 at 02:15 PM. Reason: add word |

|

|

|

|

|

#57 |

|

Senior Member

Join Date: Jul 2012

Posts: 586

|

Oh Old Henry I did not put two and two together until just now. I know more about pre war than post war-but isn't the universal joint in the clam shell? If so we are into the dreaded what type of grease to use when greasing. STP mixed with wheel bearing grease, wheel bearing grease, 10,000 weight motor oil or the John Deer corn head grease.

|

|

|

|

|

|

#58 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

|

#59 |

|

Senior Member

Join Date: Sep 2013

Location: Rochester, NY

Posts: 110

|

Old Henry, I know just what you mean. A while ago I posted comments about a noise in the drive train, and suggestions were noted about greasing the front u-joint and mid torque tube bearing. Confusion followed with not being able to find a grease fitting in the front u-joint. It took me a while to discover that the previous owner (or before that) had removed the zerk and forgot to put it back.

I decided to try to reinstall a fitting. It took a while, but I had to remove the little 90 degree head so it will thread on (wouldn't swing clear of the rear tranny mount), position it in the right clock position, so I could carefully install the small fitting. Wow, what a pain. Never thought about what you did, and lift the whole dang thing up to clear.  Jim |

|

|

|

|

|

#60 |

|

Senior Member

Join Date: May 2010

Location: new britain,ct 06052

Posts: 9,390

|

How about just take the clam shell off and work on it on the bench??

Paul in CT |

|

|

|

|

|

#61 | |

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness |

|

|

|

|

|

|

#62 | ||

|

Senior Member

Join Date: Oct 2010

Location: Orem, Utah

Posts: 5,762

|

Quote:

Quote:

Just removed my old tranny mount and on the bottom is this oblong slot for some unknown reason.  It sits over a hole in the center of the frame member upon which the tranny mount sits:  You can see that the oblong hole in the mount has not been sitting centered over the hole in the middle of the frame member - it's been toward the right side causing the crowding of the zerk I've struggled with. The clam needs to move more sideways to the left than it does need to move up to solve my problem. Hopefully I can secure the new mount and tranny toward the left and it should solve my problem without anything else being done. We'll see. Thanks again 51 MERC-CT for your astute observation.

__________________

Prof. Henry (The Roaming Gnome)  "It is good to have an end to journey toward; but it is the journey that matters, in the end.” *Ursula K. Le Guin in The Left Hand of Darkness |

||

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 01:28 PM.

Linear Mode

Linear Mode