|

|||||||

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Senior Member

Join Date: May 2012

Location: Chillicothe, Missouri

Posts: 1,175

|

I would like to set up my engine with a pressurized oiling system.

Is there a fairly simple set up people are using??? I realize the time to do this is when the engine is completely disassembled during an overhaul. Is it possible to drill the Model A crank for the connecting rod oiling? Being new to the A's, I have not seen any articles on this subject. |

|

|

|

|

|

#2 |

|

Senior Member

Join Date: May 2010

Location: Cape Cod

Posts: 1,128

|

Fullraceflathead,

What problem are you trying to solve ? If the engine stays with the stock setup, it would seem that the original oiling system works fine. Marc |

|

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

|

|

#3 |

|

Senior Member

Join Date: Apr 2011

Location: New Zealand

Posts: 444

|

I have converted my motor to Mains pressure fed following the instructions of Charlie Yapp in "The Secrets of Speed" magazine.

I felt that it was quite a complex conversion including improving the performance of the oil pump. I believe that the big ends are good for at least 3000rpm with the standard dipper set-up. With shell bearings and an F150 overdrive gearbox, I'm hoping that my speedster will cruise comfortably at 60mph. (the motor has been considerably improved but yet to run) |

|

|

|

|

|

#4 |

|

Senior Member

Join Date: Aug 2010

Location: Phoenix AZ/Bath UK

Posts: 481

|

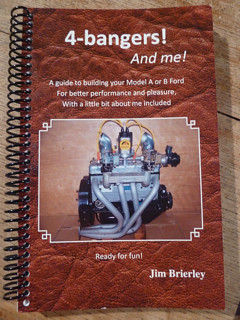

Have a look at Mr B's book

bangers by juggler29, on Flickr There is a whole chapter on pressurizing a B motor, but the principles are the same If you can't find anyone to drill your crank, Scat will sell you one for a price http://www.scatcrankshafts.com/ |

|

|

|

|

|

#5 |

|

Senior Member

Join Date: Jun 2014

Location: Melbourne, Australia

Posts: 7,496

|

DON'T DRILL A MODEL A CRANK SHAFT!

The original dippers work just fine up to about 5,000 rpm - more than you want to be doing with an A engine. The holes weaken the shaft some.

__________________

I'm part of the only ever generation with an analogue childhood and a digital adulthood. |

|

|

|

|

|

#6 |

|

Senior Member

Join Date: May 2010

Location: Southern Upstate New York

Posts: 1,160

|

Sponsored Links (Register now to hide all advertisements)

__________________

AL in NY |

|

|

|

|

|

#7 |

|

Senior Member

Join Date: May 2010

Location: Fort Worth, Texas

Posts: 1,055

|

I'll second this

__________________

Cowtown A's |

|

|

|

|

|

#8 |

|

Senior Member

Join Date: Mar 2013

Location: Australa Melbourne

Posts: 878

|

Model A dippers stop working somewhere between 3800-4000 rpm

You can drill the crank without a problem if you use the 3 angle method You will need the use modern style seal on the rear main there is a long list if work needed but it can be done If you really want a full pressure engine go with B model engine |

|

|

|

|

|

#9 | |

|

Senior Member

|

Quote:

With that said, the secrets of speed magazine is going to be your best bet. There have been numerous article written, search for FULL PRESSURE OILING on their web site and then ask if anyone has a copy of that article. http://www.secretsofspeed.com/secrets-of-speed-society

__________________

What's right about America is that although we have a mess of problems, we have great capacity - intellect and resources - to do some thing about them. - Henry Ford II |

|

|

|

|

|

|

#10 |

|

Senior Member

Join Date: Jun 2010

Location: Temecula, CA

Posts: 4,087

|

thanks juggler for the recommendation of my book. there is also a chapter on pressurizing the A block. anyone that wants the book can contact me at [email protected]

|

|

|

|

|

|

#11 |

|

Senior Member

Join Date: May 2010

Location: Nelson. New Zealand

Posts: 2,009

|

I will also endorse Jims book. & its also cheep to purchase, tons of info, Thanks for taking the time Jim to pass on your knowledge,

|

|

|

|

|

|

#12 | |

|

Senior Member

Join Date: May 2010

Location: South California

Posts: 6,188

|

Quote:

As far as drilling crank for full pressure, good luck if trying this yourself. Unless you are experienced , and good, at this....the job is best done by a crank shop, IMO. Otherwise, you may/will end up with what is in last picture and you do not need / want that, eh ! |

|

|

|

|

|

|

#13 |

|

Member

Join Date: May 2010

Location: Brum...

Posts: 51

|

I wouldn't have an A crank cross-drilled again either. Mine also ended up in two. Horrible noise when they go too...

|

|

|

|

|

|

#14 |

|

Senior Member

Join Date: May 2010

Location: NC

Posts: 2,975

|

DON'T DRILL A MODEL A CRANK SHAFT!

The original dippers work just fine up to about 5,000 rpm - more than you want to be doing with an A engine. The holes weaken the shaft some. I third this. Model A cranks are not that strong to start with. I broke two at the hill climb. They were both done right. The A crank is fine for a stock engine, but weak for a very strong engine. Drilling them just makes it easier for them to break. I'm not sure what RPMS the dippers stop working, but you won't be running 5000 RPMS long. The piston speed at 5000 RPMS with this long stroke engine is out of this world. The piston has to start and stop twice in every stroke, so good by crank. |

|

|

|

|

|

#15 |

|

Senior Member

Join Date: Jun 2010

Location: 34.22 N 118.36 W

Posts: 1,054

|

If you are dead set on fully pressurized Mod "A" I would do it this way;

Start with counterweighted "B" crank (commonly mis-labeled "C") Have the mains taken down to 1.85 dia with min .13 fillet rad. Grind rod journals if necessary. Drill for oil. Block align bore for Saturn bearing in mains. Use "B" rods of your choice. John |

|

|

|

|

|

#16 |

|

Senior Member

Join Date: Apr 2011

Location: New Zealand

Posts: 444

|

Looking at the photos, I can't see a pressure reducing valve and I can't see how the valve chamber remains full of oil (probably my lack of engineering knowledge?)

The Charlie Yapp set-up has a 25lbs pressure reducing valve in the valve chamber and with the improved oil pump the excess oil is dumped into the valve chamber keeping it full of oil. At least that's how it's supposed to work. After much searching, I found that Charlie sold the appropriate pressure reducing valve for a very reasonable price Keith |

|

|

|

|

|

#17 |

|

Senior Member

Join Date: May 2010

Location: NorCal

Posts: 2,617

|

Also looking at the pics, I'm not sure i like the epoxy. Will this hold over time and vibration?

|

|

|

|

|

|

#18 | |

|

Senior Member

Join Date: May 2010

Location: South California

Posts: 6,188

|

Quote:

Yeah, this A block was 'done' by a pretty well known A/B engine rebuilder. It was done a long number of years ago, put away and recently re-enlisted for work. It has a broken crankshaft that was drilled and the maker would be recognized by all here. I also question the epoxy use, but think that if used on clean metal it would adhere. BTW this crank broke one of the 'cut down' to A size rod throws ! I know, there are those here who state that this is a great and safe crank to use a cut down B crank. I would/will not spend any money on such a drilled crank. Heck , they cost a LOT of $ ! |

|

|

|

|

|

|

#19 | |

|

Senior Member

Join Date: Aug 2010

Location: Phoenix AZ/Bath UK

Posts: 481

|

Quote:

I've got the C crank and planned to take it down as you say, but not come across a reference to Saturn bearings before |

|

|

|

|

|

|

#20 | |

|

Senior Member

Join Date: Jun 2010

Location: 34.22 N 118.36 W

Posts: 1,054

|

Quote:

I did this a couple years ago for a Friend in his touring coupe. It was the biggest bearing I could find that did not require moving the mains bolt holes nor require cutting a notch in the bolts. You have to remember that most of the work done on Model A's was done a long time ago. I think the only Saturn back then was a planet. John |

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

|

|

| Sponsored Links (Register now to hide all advertisements) |

|

|

All times are GMT -5. The time now is 11:19 AM.

Linear Mode

Linear Mode